Selvedge denim features tightly woven edges that prevent fraying, offering a durable and premium finish often favored for high-quality jeans. Non-selvedge denim, commonly produced on modern shuttleless looms, provides more variety and typically costs less, making it suitable for everyday casual wear without the distinct edge detail.

Table of Comparison

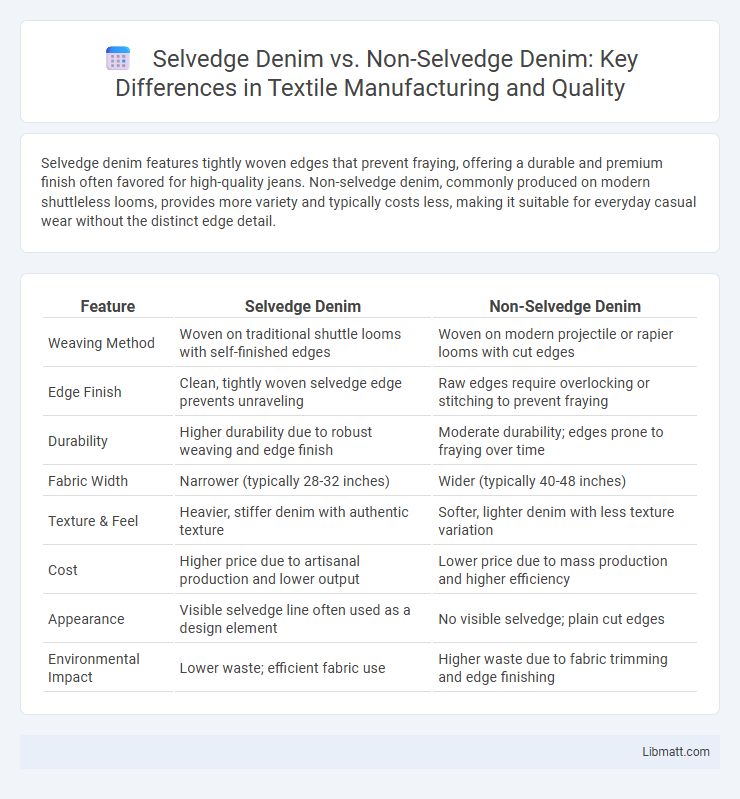

| Feature | Selvedge Denim | Non-Selvedge Denim |

|---|---|---|

| Weaving Method | Woven on traditional shuttle looms with self-finished edges | Woven on modern projectile or rapier looms with cut edges |

| Edge Finish | Clean, tightly woven selvedge edge prevents unraveling | Raw edges require overlocking or stitching to prevent fraying |

| Durability | Higher durability due to robust weaving and edge finish | Moderate durability; edges prone to fraying over time |

| Fabric Width | Narrower (typically 28-32 inches) | Wider (typically 40-48 inches) |

| Texture & Feel | Heavier, stiffer denim with authentic texture | Softer, lighter denim with less texture variation |

| Cost | Higher price due to artisanal production and lower output | Lower price due to mass production and higher efficiency |

| Appearance | Visible selvedge line often used as a design element | No visible selvedge; plain cut edges |

| Environmental Impact | Lower waste; efficient fabric use | Higher waste due to fabric trimming and edge finishing |

Introduction to Selvedge and Non-Selvedge Denim

Selvedge denim is woven on traditional shuttle looms, producing tightly woven edges that prevent unraveling and provide a clean, finished look prized for durability and aesthetics. Non-selvedge denim is typically made on modern projectile looms, allowing faster production but resulting in edges that fray without additional stitching. The distinctive characteristics of selvedge denim, such as its selvage ID and slower production process, make it a premium choice compared to the mass-produced non-selvedge denim.

What is Selvedge Denim?

Selvedge denim is a high-quality fabric woven on traditional shuttle looms, characterized by its tightly woven edges that prevent unraveling and fraying. This denim features a clean, finished edge with a distinct colored thread, often red, running along the selvage, making it easily recognizable and preferred for premium jeans. When choosing denim, your decision between selvedge and non-selvedge impacts durability, comfort, and style due to differences in production methods and fabric quality.

What is Non-Selvedge Denim?

Non-selvedge denim is a type of denim fabric produced on modern, wider shuttleless looms, resulting in a fabric without the tightly woven edges characteristic of selvedge denim. Unlike selvedge denim, non-selvedge denim edges are typically finished with overlock stitching to prevent unraveling, which makes them easier and faster to produce. This denim is often used in mass-market jeans due to its lower production cost and availability in wider rolls.

Key Differences Between Selvedge and Non-Selvedge Denim

Selvedge denim is woven on traditional shuttle looms, producing tightly woven edges that prevent fraying, while non-selvedge denim is made on modern projectile looms with a looser weave and unfinished edges. The narrow width of selvedge fabric leads to a higher quality, denser denim with distinctive colored edge lines visible when cuffed, contrasting with the wider, mass-produced non-selvedge fabric that lacks these signature edges. Selvedge denim is typically more durable and ages uniquely due to its construction, whereas non-selvedge denim offers more variety in texture and stretch but may wear out faster over time.

Weaving Techniques and Fabric Construction

Selvedge denim is crafted using traditional shuttle looms that create tightly woven fabric with clean, finished edges, preventing unraveling and showcasing a distinctive selvedge ID. Non-selvedge denim employs modern projectile looms for faster, wider fabric production but results in unfinished edges requiring additional stitching to prevent fraying. Your choice between these fabrics impacts durability, texture, and the authenticity of the denim's construction.

Durability and Longevity Comparison

Selvedge denim is renowned for its exceptional durability due to its tightly woven edges that prevent fraying and unraveling, extending the garment's lifespan significantly. Non-selvedge denim, often produced on wider, modern looms, lacks these self-finished edges, making it more prone to wear and tear over time. The dense weave and high-quality cotton used in selvedge denim contribute to enhanced longevity, making it a preferred choice for those seeking long-lasting jeans.

Aesthetic and Style Differences

Selvedge denim features tightly woven edges that create a clean, finished look often revealed in cuffed jeans, appealing to those who value craftsmanship and vintage-inspired style. Non-selvedge denim lacks this distinctive edge, typically produced on modern looms, resulting in a softer fabric with less structural rigidity and a more casual, mainstream appearance. Your choice between the two affected by preference for sharp, authentic detailing versus versatility and ease of wear in everyday fashion.

Pricing and Value Considerations

Selvedge denim typically commands a higher price due to its traditional shuttle loom production, superior craftsmanship, and durability, offering long-term value for denim enthusiasts. Non-selvedge denim is often less expensive and mass-produced on modern projectile looms, making it more accessible but generally less durable and unique in character. Your choice depends on whether you prioritize premium quality and longevity or affordability and availability in denim options.

Environmental and Ethical Impacts

Selvedge denim is often crafted using traditional shuttle looms, resulting in less fabric waste and a lower environmental footprint compared to the mass-produced, non-selvedge denim made on modern projectile looms. The slow, artisanal production of selvedge denim supports fair labor practices by emphasizing quality over quantity, while many non-selvedge denim manufacturers prioritize speed and volume, often leading to questionable ethical standards. Choosing selvedge denim aligns with your values by promoting sustainability and responsible manufacturing in the fashion industry.

Choosing the Right Denim for You

Selvedge denim features tightly woven edges that prevent fraying, providing superior durability and a premium look, ideal for those seeking longevity and a vintage aesthetic. Non-selvedge denim, produced on wider modern looms, is more affordable and widely available, suitable for casual wear and mass-market fashion. Choosing the right denim depends on desired longevity, budget, and style preferences, with selvedge denim favored for quality and craftsmanship, while non-selvedge denim offers versatility and accessibility.

Selvedge denim vs Non-selvedge denim Infographic

libmatt.com

libmatt.com