Stitch bonding creates strong, flexible fabrics by interlocking fibers with needle-punched stitches, offering enhanced durability and dimensional stability compared to traditional needle punching, which mechanically entangles fibers without added stitching. Your choice depends on the need for a more robust, stable textile or a quicker, cost-effective material primarily used for filtration or insulation.

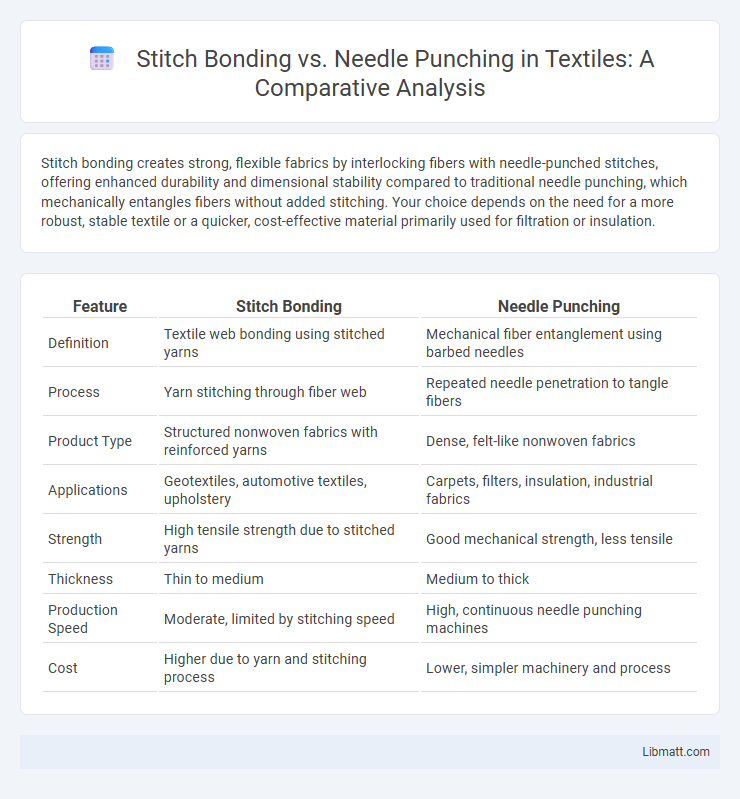

Table of Comparison

| Feature | Stitch Bonding | Needle Punching |

|---|---|---|

| Definition | Textile web bonding using stitched yarns | Mechanical fiber entanglement using barbed needles |

| Process | Yarn stitching through fiber web | Repeated needle penetration to tangle fibers |

| Product Type | Structured nonwoven fabrics with reinforced yarns | Dense, felt-like nonwoven fabrics |

| Applications | Geotextiles, automotive textiles, upholstery | Carpets, filters, insulation, industrial fabrics |

| Strength | High tensile strength due to stitched yarns | Good mechanical strength, less tensile |

| Thickness | Thin to medium | Medium to thick |

| Production Speed | Moderate, limited by stitching speed | High, continuous needle punching machines |

| Cost | Higher due to yarn and stitching process | Lower, simpler machinery and process |

Introduction to Nonwoven Fabric Technologies

Nonwoven fabric technologies include stitch bonding and needle punching, both essential for creating durable textile materials without traditional weaving or knitting. Stitch bonding involves interlocking fibers through sewing threads, producing strong, flexible fabrics ideal for automotive and upholstery applications. Needle punching mechanically entangles fibers using barbed needles, resulting in dense, felt-like materials commonly used in geotextiles and filtration products.

What is Stitch Bonding?

Stitch bonding is a textile manufacturing technique that involves interlocking layers of fibers or nonwoven fabrics using stitching with strong threads, creating a durable and flexible material. This method provides enhanced structural integrity and resilience compared to needle punching, which mechanically entangles fibers without thread. Stitch bonding is commonly used in geotextiles, automotive textiles, and upholstery for its superior strength and dimensional stability.

What is Needle Punching?

Needle punching is a mechanical bonding process that entangles fibers using barbed needles to create nonwoven fabrics with enhanced strength and durability. This technique is widely used in filtration, insulation, and geotextiles due to its ability to produce dense, uniform mats without adhesives or heat. Your choice between stitch bonding and needle punching depends on the required fabric properties, as needle punching offers superior thickness and resilience.

Stitch Bonding: Process Overview

Stitch bonding is a textile manufacturing process where fiber webs are mechanically interlaced using stitching threads to form a strong, flexible fabric. This technique employs multi-needle stitching machines that create a stable network of threads, enhancing the material's dimensional stability and durability. Unlike needle punching, stitch bonding allows for precise control over thread density and pattern, resulting in tailored fabric properties for various industrial applications.

Needle Punching: Process Overview

Needle punching is a mechanical process where barbed needles repeatedly punch fibers through a web to entangle and bond them, creating a durable nonwoven fabric. This technique enhances fabric strength and thickness by interlocking fibers without the need for adhesives or heat. Your choice of needle punching allows for versatile applications in geotextiles, automotive, and filtration industries due to its robust fabric properties.

Key Differences Between Stitch Bonding and Needle Punching

Stitch bonding involves using thread to interlock layers of fabric, creating strong, flexible textiles often used in automotive and upholstery applications. Needle punching mechanically entangles fibers through barbed needles, producing dense, durable nonwoven mats commonly utilized in geotextiles and filtration. The key differences lie in the bonding technique--stitch bonding uses thread loops, while needle punching relies on fiber entanglement--affecting product strength, texture, and application suitability.

Performance Comparison: Durability, Strength, and Flexibility

Stitch bonding offers enhanced durability and strength due to its interlooping technique, which creates a more uniform and stable fabric structure compared to needle punching. Needle punching provides superior flexibility and softness, making it ideal for applications requiring pliability, but it may exhibit lower tensile strength and abrasion resistance. The choice between stitch bonding and needle punching depends on the specific performance requirements, with stitch bonding favored in heavy-duty uses and needle punching preferred for flexible, cushioning materials.

Applications of Stitch Bonded Fabrics

Stitch bonded fabrics are widely used in automotive upholstery, geotextiles, and mattress covers due to their enhanced durability and dimensional stability. These fabrics offer superior strength and breathability, making them ideal for filtration media and insulation products. Their ability to combine different fiber types also supports applications in furniture padding and protective clothing.

Applications of Needle Punched Fabrics

Needle punched fabrics are widely used in filtration, geotextiles, automotive interiors, and upholstery due to their durability and permeability. These nonwoven textiles provide excellent mechanical strength and abrasion resistance, making them ideal for industrial applications such as insulation and carpet backing. Your choice of needle punched fabric ensures high performance in environments requiring robust and stable materials.

Choosing the Right Method: Factors to Consider

Choosing between stitch bonding and needle punching depends primarily on the desired fabric strength, texture, and application. Stitch bonding offers superior dimensional stability and tensile strength, making it ideal for technical textiles and geotextiles. Needle punching provides a bulkier, more textured fabric suitable for filtration, insulation, and carpeting, where porosity and cushioning are key factors.

Stitch bonding vs Needle punching Infographic

libmatt.com

libmatt.com