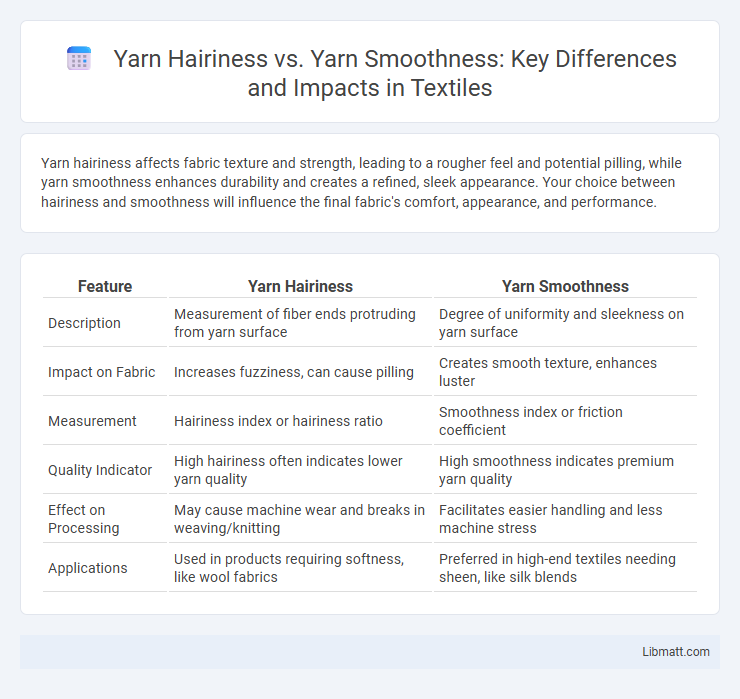

Yarn hairiness affects fabric texture and strength, leading to a rougher feel and potential pilling, while yarn smoothness enhances durability and creates a refined, sleek appearance. Your choice between hairiness and smoothness will influence the final fabric's comfort, appearance, and performance.

Table of Comparison

| Feature | Yarn Hairiness | Yarn Smoothness |

|---|---|---|

| Description | Measurement of fiber ends protruding from yarn surface | Degree of uniformity and sleekness on yarn surface |

| Impact on Fabric | Increases fuzziness, can cause pilling | Creates smooth texture, enhances luster |

| Measurement | Hairiness index or hairiness ratio | Smoothness index or friction coefficient |

| Quality Indicator | High hairiness often indicates lower yarn quality | High smoothness indicates premium yarn quality |

| Effect on Processing | May cause machine wear and breaks in weaving/knitting | Facilitates easier handling and less machine stress |

| Applications | Used in products requiring softness, like wool fabrics | Preferred in high-end textiles needing sheen, like silk blends |

Introduction to Yarn Hairiness and Smoothness

Yarn hairiness refers to the presence of fiber ends protruding from the yarn surface, influencing fabric texture, appearance, and pilling tendency. Yarn smoothness describes the uniformity and compactness of the yarn structure, affecting fabric strength, sheen, and hand feel. Both hairiness and smoothness are critical parameters in textile production, impacting processing efficiency and end-product quality.

Defining Yarn Hairiness: Key Characteristics

Yarn hairiness refers to the protrusion of short fibers from the yarn surface, affecting its texture and appearance by creating a fuzzy or rough feel. Key characteristics include fiber length distribution, spinning method, and fiber type, which influence the amount of hairiness and its impact on fabric properties such as pilling and friction. Understanding yarn hairiness helps you optimize fabric performance and aesthetic by balancing softness and durability against smoothness.

Understanding Yarn Smoothness: Core Attributes

Yarn smoothness is determined by fiber alignment, twist level, and consistent fiber length, which reduce protruding fibers that cause hairiness. Core attributes include the yarn's surface evenness and the tightly bound fibers that enhance fabric texture and durability. Your choice of a smoother yarn improves fabric softness, appearance, and reduces pilling during wear and washing.

Factors Influencing Yarn Hairiness

Yarn hairiness is primarily influenced by fiber length, fiber fineness, and spinning process parameters, where shorter fibers and coarser fibers increase hairiness by producing more protruding fiber ends. Fiber alignment during spinning and the twist level also affect yarn smoothness, as higher twist and better fiber parallelization reduce hairiness, enhancing yarn compactness and surface uniformity. Environmental factors such as humidity and fiber treatments, including chemical finishes, further modify yarn hairiness by altering fiber surface friction and flexibility.

Determinants of Yarn Smoothness

Yarn smoothness is primarily determined by fiber length, fineness, and the degree of fiber alignment within the yarn structure. Longer, finer fibers with consistent alignment reduce protruding fiber ends, minimizing hairiness and enhancing smoothness. The spinning technique and finishing processes also play crucial roles in controlling fiber cohesion and surface texture, directly impacting yarn smoothness.

Measurement Techniques for Yarn Hairiness and Smoothness

Measuring yarn hairiness typically involves advanced imaging techniques such as digital microscopy or high-speed cameras that count protruding fibers per unit length, providing precise quantification of surface fiber length and density. Yarn smoothness is often assessed using frictional coefficient testers or tension analyzers that evaluate the yarn's surface irregularities and resistance to movement under controlled conditions. Your choice of measurement techniques directly influences fabric quality by identifying yarn attributes critical for processing efficiency and end-product performance.

Impact of Fiber Type on Hairiness and Smoothness

Fiber type significantly influences yarn hairiness and smoothness, with natural fibers like cotton and wool typically producing higher hairiness due to their irregular surface structures, while synthetic fibers such as polyester and nylon often yield smoother yarns because of their uniform filament shape. The inherent length, fineness, and surface properties of the fiber determine the degree of fiber protrusion and friction, directly affecting yarn texture and fabric appearance. Understanding your fiber selection allows for better control over yarn performance and fabric quality in textile applications.

Effects on Textile Processing and Product Quality

Yarn hairiness significantly impacts textile processing by increasing friction and causing frequent machine stoppages due to fiber entanglement, which reduces production efficiency. In contrast, yarn smoothness enhances processing performance by minimizing fiber protrusions, resulting in fewer breaks and smoother fabric surfaces. Product quality is improved with smoother yarns, yielding textiles with better appearance, durability, and comfort, while excessive hairiness often leads to pilling and uneven texture.

Comparative Analysis: Hairy Yarns vs Smooth Yarns

Hairy yarns exhibit increased fiber ends protruding from the surface, enhancing fabric warmth and texture but potentially causing pilling and reduced durability. Smooth yarns feature tightly twisted fibers with minimal protrusion, resulting in sleek, lustrous fabrics favored for strength, abrasion resistance, and a polished appearance. Your selection between hairy and smooth yarns directly impacts fabric performance, influencing comfort, longevity, and aesthetic appeal based on the intended textile application.

Strategies for Controlling Yarn Hairiness and Enhancing Smoothness

Controlling yarn hairiness involves optimizing fiber selection, using combing and carding techniques to remove short fibers, and adjusting spinning parameters such as twist level and tension to reduce fiber protrusion. Enhancing yarn smoothness can be achieved by employing ring spinning or compact spinning methods, applying appropriate finishing treatments like singeing or calendaring, and selecting fibers with longer staple length and uniform fineness. Your choice of these strategies directly impacts the fabric's texture, appearance, and performance, ensuring higher quality and improved end-use characteristics.

Yarn Hairiness vs Yarn Smoothness Infographic

libmatt.com

libmatt.com