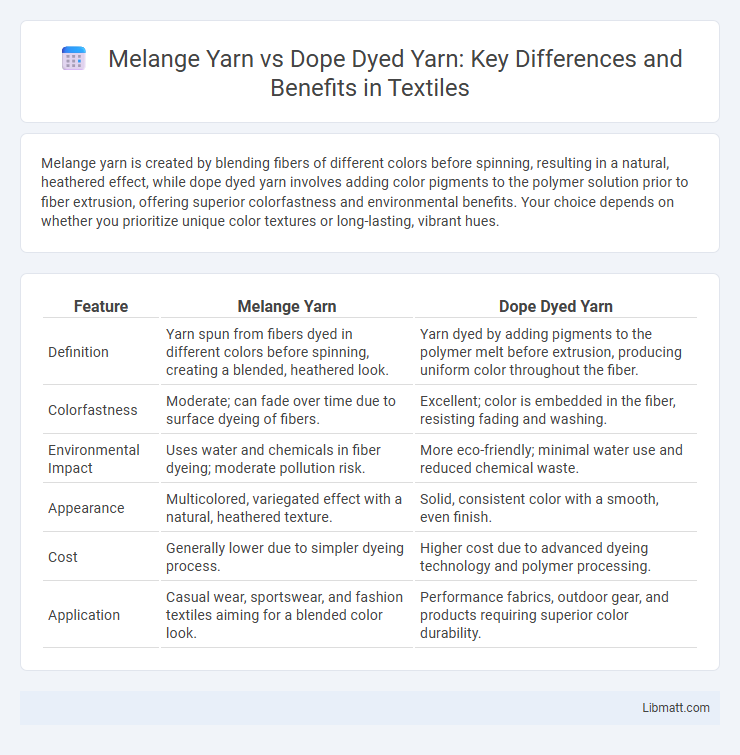

Melange yarn is created by blending fibers of different colors before spinning, resulting in a natural, heathered effect, while dope dyed yarn involves adding color pigments to the polymer solution prior to fiber extrusion, offering superior colorfastness and environmental benefits. Your choice depends on whether you prioritize unique color textures or long-lasting, vibrant hues.

Table of Comparison

| Feature | Melange Yarn | Dope Dyed Yarn |

|---|---|---|

| Definition | Yarn spun from fibers dyed in different colors before spinning, creating a blended, heathered look. | Yarn dyed by adding pigments to the polymer melt before extrusion, producing uniform color throughout the fiber. |

| Colorfastness | Moderate; can fade over time due to surface dyeing of fibers. | Excellent; color is embedded in the fiber, resisting fading and washing. |

| Environmental Impact | Uses water and chemicals in fiber dyeing; moderate pollution risk. | More eco-friendly; minimal water use and reduced chemical waste. |

| Appearance | Multicolored, variegated effect with a natural, heathered texture. | Solid, consistent color with a smooth, even finish. |

| Cost | Generally lower due to simpler dyeing process. | Higher cost due to advanced dyeing technology and polymer processing. |

| Application | Casual wear, sportswear, and fashion textiles aiming for a blended color look. | Performance fabrics, outdoor gear, and products requiring superior color durability. |

Introduction to Melange Yarn and Dope Dyed Yarn

Melange yarn is created by blending fibers of different colors before spinning, resulting in a unique, heathered appearance with rich texture and depth. Dope dyed yarn, also known as solution-dyed yarn, involves adding pigments directly to the polymer solution before fiber extrusion, ensuring vibrant, long-lasting colors with superior colorfastness. Understanding these distinct manufacturing processes helps you choose the right yarn for durability, aesthetics, and eco-friendly textile production.

What is Melange Yarn?

Melange yarn is produced by blending fibers of different colors before spinning, creating a unique, multi-tonal effect in the fabric. This technique enhances depth and texture in textiles, often used in fashion and home decor for its distinctive, heathered appearance. Unlike dope dyed yarn, which involves adding color to polymers before fiber extrusion, melange yarn achieves its visual appeal through fiber blending.

Understanding Dope Dyed Yarn

Dope dyed yarn is created by adding color pigments directly into the polymer solution before the fiber is spun, ensuring vibrant and long-lasting colors that resist fading and washing out. This method contrasts with melange yarn, which is produced by blending fibers of different colors prior to spinning, resulting in a heathered or mixed color effect. Understanding dope dyed yarn highlights its eco-friendly benefits due to reduced water and chemical use, offering your textiles enhanced durability and sustainability.

Key Differences Between Melange and Dope Dyed Yarns

Melange yarn is created by blending fibers of different colors before spinning, resulting in a heathered, multi-tonal effect, whereas dope dyed yarn involves adding pigments to the polymer solution before extrusion, producing vibrant, colorfast fibers with consistent coloration. Melange yarn offers unique visual texture and depth due to the fiber mix, while dope dyed yarn excels in environmental sustainability by reducing water and chemical use in the dyeing process. Understanding these key differences helps you choose the right yarn based on aesthetic preference and eco-friendly manufacturing priorities.

Color Consistency and Variety

Melange yarn offers rich color variety by blending different dyed fibers before spinning, resulting in unique, heathered effects but less precise color consistency. Dope dyed yarn exhibits superior color consistency and durability since pigments are added to the polymer solution prior to fiber formation, ensuring uniform coloration throughout. Brands seeking vibrant yet stable colors in textiles often prefer dope dyed yarn for its long-lasting hues and environmental benefits.

Environmental Impact: Melange vs Dope Dyed Yarn

Melange yarn production typically involves dyeing fibers before spinning, leading to higher water and chemical usage compared to dope dyed yarn, which integrates color into fibers during polymer extrusion, significantly reducing water pollution and chemical waste. Dope dyed yarns offer superior sustainability by minimizing energy consumption and emissions associated with traditional dyeing processes. Consequently, dope dyed yarns present a more environmentally responsible choice for textile manufacturing focused on reducing ecological footprint.

Production Processes Compared

Melange yarn is produced by blending fibers of different colors before spinning, creating a heathered or mottled effect, while Dope dyed yarn involves adding color pigments to the polymer solution before the fiber is formed, resulting in deeply saturated and colorfast fibers. Melange yarn production allows for greater variety and subtle color combinations but often requires more energy and water during fiber blending and dyeing stages. Your choice between these yarns impacts sustainability, with Dope dyed yarn generally offering better environmental performance due to reduced water usage and fewer chemicals in the dyeing process.

Applications and Usage in Textiles

Melange yarn, created by blending fibers of different colors before spinning, is widely used in fashion textiles for achieving subtle heathered effects in garments like t-shirts, sweaters, and activewear. Dope dyed yarn, where color pigments are added during the fiber extrusion process, is preferred in eco-friendly textiles due to its superior colorfastness and reduced water usage, making it ideal for outdoor apparel, upholstery, and technical fabrics. Your choice between melange and dope dyed yarn should consider the end-use requirements, including aesthetic appeal, durability, and environmental impact in textile applications.

Cost and Market Availability

Melange yarn typically incurs higher production costs due to the intricate dyeing of fibers before spinning, resulting in limited scalability and higher market prices. Dope dyed yarn offers cost-efficiency through pigment incorporation during fiber extrusion, enabling mass production with consistent colorfastness and greater market availability. Manufacturers and textile buyers often favor dope dyed yarn for budget-sensitive projects requiring uniform coloration and sustainable dyeing processes.

Choosing the Right Yarn for Your Needs

Melange yarn combines fibers of different colors spun together, offering a unique, textured appearance ideal for fashion garments requiring a natural, variegated look. Dope dyed yarn is colored during the fiber extrusion process, providing vibrant, long-lasting hues with excellent colorfastness and environmental benefits due to reduced water usage. Choosing the right yarn depends on whether you prioritize aesthetic depth with melange yarn or durability and sustainability with dope dyed yarn for your textile projects.

Melange yarn vs Dope dyed yarn Infographic

libmatt.com

libmatt.com