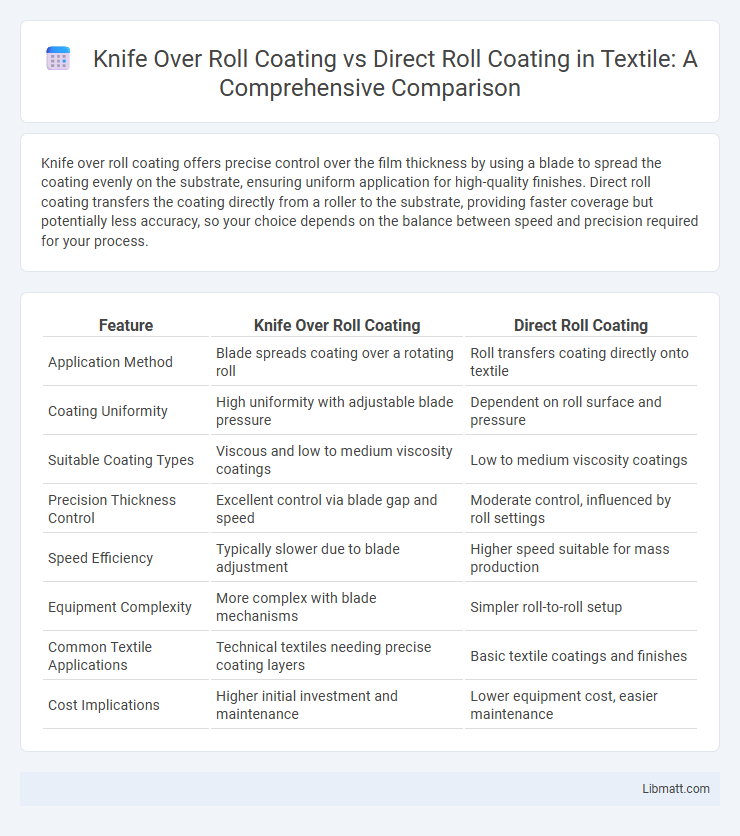

Knife over roll coating offers precise control over the film thickness by using a blade to spread the coating evenly on the substrate, ensuring uniform application for high-quality finishes. Direct roll coating transfers the coating directly from a roller to the substrate, providing faster coverage but potentially less accuracy, so your choice depends on the balance between speed and precision required for your process.

Table of Comparison

| Feature | Knife Over Roll Coating | Direct Roll Coating |

|---|---|---|

| Application Method | Blade spreads coating over a rotating roll | Roll transfers coating directly onto textile |

| Coating Uniformity | High uniformity with adjustable blade pressure | Dependent on roll surface and pressure |

| Suitable Coating Types | Viscous and low to medium viscosity coatings | Low to medium viscosity coatings |

| Precision Thickness Control | Excellent control via blade gap and speed | Moderate control, influenced by roll settings |

| Speed Efficiency | Typically slower due to blade adjustment | Higher speed suitable for mass production |

| Equipment Complexity | More complex with blade mechanisms | Simpler roll-to-roll setup |

| Common Textile Applications | Technical textiles needing precise coating layers | Basic textile coatings and finishes |

| Cost Implications | Higher initial investment and maintenance | Lower equipment cost, easier maintenance |

Introduction to Roll Coating Techniques

Roll coating techniques involve applying a uniform layer of liquid materials onto substrates, critical for industries like printing, packaging, and electronics. Knife over roll coating uses a fixed blade that meters the coating thickness by controlling the gap between the knife and the substrate, providing precise film thickness and smooth surface finish. Direct roll coating employs a roller immersed in the coating solution that directly transfers the liquid onto the substrate, enabling high-speed application with good wetting properties and minimal waste.

Overview of Knife Over Roll Coating

Knife over roll coating involves a precision steel or polymer knife positioned closely above a rotating roll to control the thickness of the applied liquid or viscous coating on substrates such as paper, film, or metal. This method ensures uniform coating layers with high accuracy, making it ideal for processes requiring strict thickness tolerances. The technique's ability to adjust the knife gap and pressure provides versatility in producing varied coating weights while maintaining consistent surface quality.

Understanding Direct Roll Coating

Direct roll coating involves applying a liquid or slurry directly onto a substrate using a roll in constant contact, enabling precise control over coating thickness and uniformity. Unlike knife over roll coating, which uses a blade to meter the coating, the direct roll method reduces material waste by minimizing excess and spillage. Your production process can benefit from improved speed and efficiency when leveraging direct roll coating for thin, consistent film applications.

Key Differences Between Knife Over Roll and Direct Roll Coating

Knife over roll coating uses a blade to control film thickness by shearing excess liquid off a rotating roll, ensuring precise, consistent coating thickness. Direct roll coating applies the coating directly from one roll to another without a blade, resulting in thicker, less uniform layers suitable for viscous materials. Key differences include film thickness control, coating uniformity, and suitability for different viscosities.

Advantages of Knife Over Roll Coating

Knife over roll coating offers precise control over the film thickness, ensuring uniform application and consistent quality in high-speed production processes. This method reduces material waste by allowing accurate metering of coatings, enhancing cost efficiency and minimizing defects. The ability to handle a wide range of viscosities and coatings increases versatility across industries such as packaging, electronics, and automotive manufacturing.

Benefits of Direct Roll Coating

Direct roll coating offers superior coating uniformity and reduced material waste compared to knife over roll coating, enhancing product quality and cost-efficiency. The process minimizes the risk of coating defects by applying the material directly with controlled pressure, which boosts production speed and consistency. Your manufacturing line benefits from simplified setup and maintenance, ensuring faster turnaround times and less downtime.

Common Applications for Each Coating Method

Knife over roll coating is commonly used for precise application of adhesive films, protective coatings, and decorative laminates on substrates requiring uniform thickness, such as in packaging, automotive, and electronics industries. Direct roll coating is preferred for high-speed applications involving paints, varnishes, and inks on paper, metal, and plastic surfaces, typical in printing, metal finishing, and textile manufacturing. Both methods optimize material usage and surface quality but cater to different production speeds and coating uniformity requirements.

Material and Substrate Compatibility

Knife over roll coating offers superior control for applying viscous materials and thicker coatings on rigid or semi-rigid substrates, ensuring even distribution and precise thickness. Direct roll coating excels with low to medium viscosity liquids and is ideal for smooth, flexible substrates where surface tension and adhesion are critical. Your choice between these methods depends on matching the coating material's viscosity and the substrate's surface properties to achieve optimal adhesion and finish quality.

Factors Influencing Coating Method Selection

Factors influencing the selection between knife over roll coating and direct roll coating include the viscosity and composition of the coating material, substrate type, and desired film thickness. Knife over roll coating offers precise thickness control, making it ideal for uniform coatings on smooth substrates, while direct roll coating suits higher viscosity materials and textured surfaces. Your choice depends on production speed requirements, cost constraints, and the final product's quality specifications.

Future Trends in Roll Coating Technologies

Future trends in roll coating technologies emphasize enhancing precision and efficiency, with knife over roll coating offering superior control over film thickness compared to direct roll coating. Innovations in intelligent sensor integration and automation aim to optimize coating uniformity and reduce material waste, benefiting Your manufacturing processes. Advances in eco-friendly coatings and energy-efficient curing methods are also driving industry adoption toward more sustainable and cost-effective roll coating solutions.

Knife over roll coating vs Direct roll coating Infographic

libmatt.com

libmatt.com