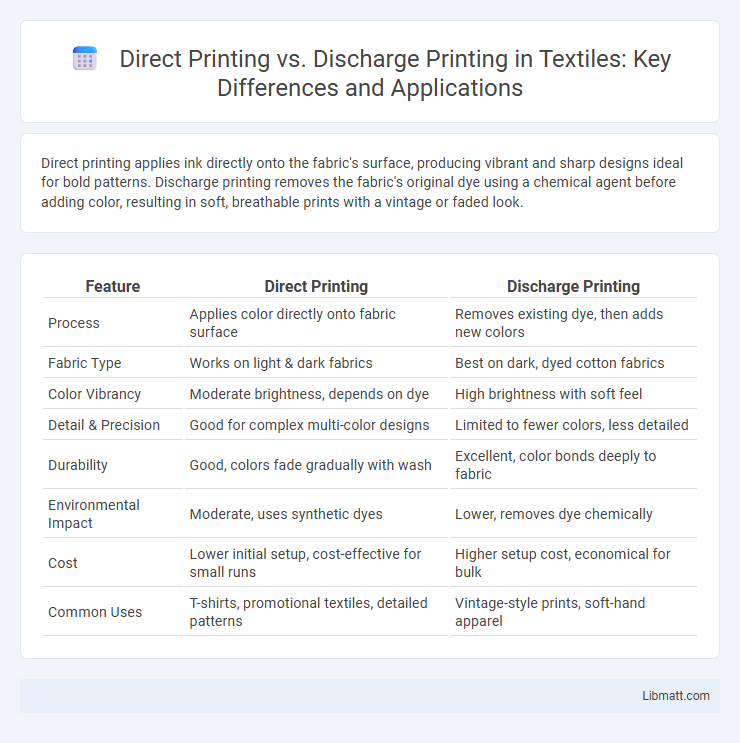

Direct printing applies ink directly onto the fabric's surface, producing vibrant and sharp designs ideal for bold patterns. Discharge printing removes the fabric's original dye using a chemical agent before adding color, resulting in soft, breathable prints with a vintage or faded look.

Table of Comparison

| Feature | Direct Printing | Discharge Printing |

|---|---|---|

| Process | Applies color directly onto fabric surface | Removes existing dye, then adds new colors |

| Fabric Type | Works on light & dark fabrics | Best on dark, dyed cotton fabrics |

| Color Vibrancy | Moderate brightness, depends on dye | High brightness with soft feel |

| Detail & Precision | Good for complex multi-color designs | Limited to fewer colors, less detailed |

| Durability | Good, colors fade gradually with wash | Excellent, color bonds deeply to fabric |

| Environmental Impact | Moderate, uses synthetic dyes | Lower, removes dye chemically |

| Cost | Lower initial setup, cost-effective for small runs | Higher setup cost, economical for bulk |

| Common Uses | T-shirts, promotional textiles, detailed patterns | Vintage-style prints, soft-hand apparel |

Introduction to Fabric Printing Techniques

Direct printing deposits dye or pigment directly onto the fabric surface, creating vibrant and precise designs ideal for intricate patterns. Discharge printing removes color from dyed fabrics using chemicals, resulting in soft, breathable prints with a vintage or washed-out look. Understanding these techniques helps you choose the best method for achieving your desired fabric texture and visual effect.

What is Direct Printing?

Direct printing is a textile printing technique where dye or pigment is applied directly onto the fabric's surface, creating patterns or designs without the need for intermediate transfer. This method allows for vibrant colors and sharp details, making it suitable for various fibers including cotton, polyester, and blends. Unlike discharge printing, direct printing does not remove or alter the base fabric color but adds the design on top, providing versatility in artistic expression.

What is Discharge Printing?

Discharge printing is a textile printing method that removes color from dyed fabric using a chemical agent, creating vibrant designs by bleaching specific areas. Unlike direct printing, which applies pigment or dye onto fabric surfaces, discharge printing selectively removes the original dye, resulting in soft, bright patterns with excellent color fastness. Your choice between direct and discharge printing depends on the desired fabric texture, color intensity, and design complexity.

Key Differences Between Direct and Discharge Printing

Direct printing applies pigment or dye directly onto the fabric's surface, resulting in vibrant, detailed designs suitable for various textile types. Discharge printing involves removing dye from a pre-dyed fabric using a chemical agent, producing softer prints with vintage or muted tones on dark-colored materials. The key differences lie in color vibrancy, fabric compatibility, and the printing method's impact on fabric texture and durability.

Materials and Fabric Suitability

Direct printing works well on a variety of fabrics including cotton, polyester, and blends, offering versatility for different textile types but may have limited color vibrancy on darker materials. Discharge printing is specifically suited for 100% cotton fabrics, as it involves removing dye to create vibrant designs on dark textiles without adding additional layers of ink. Choosing between these methods depends on your fabric type and the desired print quality, with discharge printing providing softer, more breathable prints on natural fibers.

Color Vibrancy and Design Complexity

Direct printing delivers high color vibrancy by applying ink directly onto fabric, preserving bold and vivid hues ideal for intricate designs. Discharge printing removes dye from the fabric base before adding color, producing softer, vintage-style shades but excels at maintaining fine design details on darker textiles. Your choice depends on whether you prioritize bright, vibrant colors or subtle tones with high design complexity.

Environmental Impact and Chemical Usage

Direct printing typically uses plastisol inks that contain PVC and phthalates, leading to higher chemical waste and environmental concerns during production and disposal. Discharge printing employs water-based inks with discharge agents that remove dye from fabric fibers, reducing plastic waste but involving hazardous chemicals like zinc formaldehyde sulfoxylate. You can minimize environmental impact by choosing discharge printing with proper chemical handling and waste treatment practices.

Durability and Wash Fastness

Direct printing applies dye or pigment directly onto the fabric surface, offering vibrant colors but may have lower durability and wash fastness compared to discharge printing. Discharge printing removes dye from the fabric with a chemical agent, creating soft, breathable designs with superior color retention and enhanced wash fastness over time. Your choice depends on the desired fabric feel and longevity, with discharge printing excelling in durability and resistance to fading after multiple washes.

Cost Comparison and Production Considerations

Direct printing generally incurs lower setup costs and faster turnaround times, making it ideal for small to medium production runs. Discharge printing demands higher initial investment due to complex processes but offers superior color vibrancy and softness, enhancing product quality in large-scale orders. Your choice depends on balancing budget constraints with the desired fabric feel and volume efficiency.

Choosing the Right Printing Method for Your Project

Direct printing offers vibrant, detailed designs by applying ink directly onto fabric, making it ideal for small runs and complex graphics. Discharge printing removes dye from the fabric, creating soft, breathable prints with a vintage look, best suited for darker textiles and large production runs. Evaluating fabric type, design complexity, budget, and desired texture ensures selecting the optimal printing method for your project's success.

Direct printing vs Discharge printing Infographic

libmatt.com

libmatt.com