Yarn strength refers to the tensile strength of individual fibers or yarns, determining their ability to withstand tension without breaking, while fabric strength describes the overall durability and resistance of the woven or knitted textile to stress and wear. Understanding the differences between yarn strength and fabric strength helps you choose materials that meet the performance requirements of your textile products.

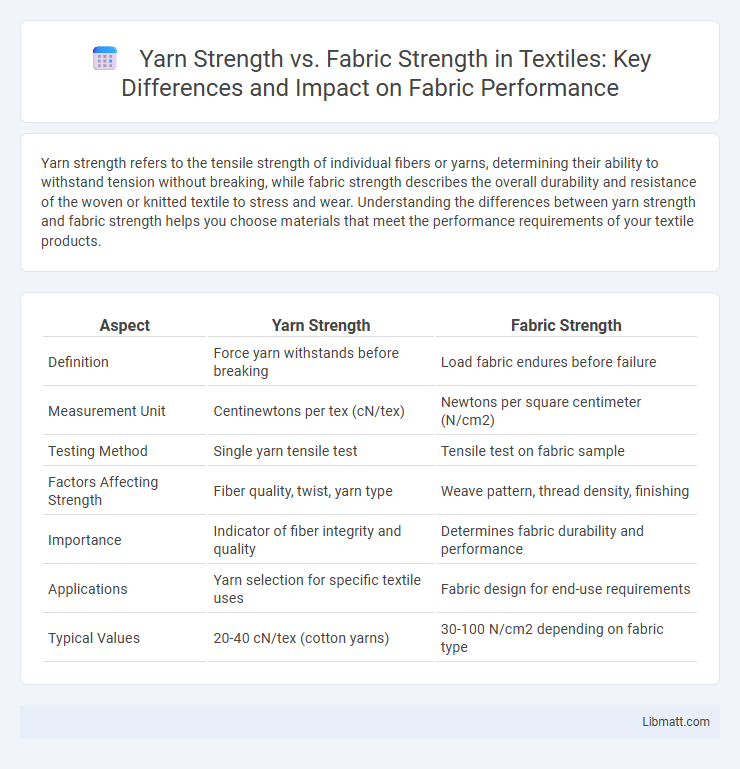

Table of Comparison

| Aspect | Yarn Strength | Fabric Strength |

|---|---|---|

| Definition | Force yarn withstands before breaking | Load fabric endures before failure |

| Measurement Unit | Centinewtons per tex (cN/tex) | Newtons per square centimeter (N/cm2) |

| Testing Method | Single yarn tensile test | Tensile test on fabric sample |

| Factors Affecting Strength | Fiber quality, twist, yarn type | Weave pattern, thread density, finishing |

| Importance | Indicator of fiber integrity and quality | Determines fabric durability and performance |

| Applications | Yarn selection for specific textile uses | Fabric design for end-use requirements |

| Typical Values | 20-40 cN/tex (cotton yarns) | 30-100 N/cm2 depending on fabric type |

Introduction to Yarn and Fabric Strength

Yarn strength measures the force required to break individual yarns, directly influencing fabric durability and performance. Fabric strength depends on both yarn strength and the weaving or knitting structure, which distributes stress across the textile. Understanding the interplay between yarn tensile properties and fabric construction is essential for optimizing overall material resilience and quality.

Defining Yarn Strength

Yarn strength refers to the maximum tensile force a single yarn can withstand before breaking, determined by factors such as fiber quality, twist level, and yarn structure. Fabric strength, on the other hand, measures the overall durability of the woven or knitted textile, influenced by yarn strength, fabric construction, and finishing processes. Understanding yarn strength is crucial for ensuring your fabric meets the desired performance and durability standards in applications ranging from apparel to industrial textiles.

Understanding Fabric Strength

Understanding fabric strength involves recognizing how yarn strength contributes to the overall durability of the textile. Fabric strength depends on the tensile strength of individual yarns and the method of construction, such as weaving or knitting, which affects how stress is distributed. Your choice of yarn with higher tensile strength enhances fabric performance, making it more resistant to tearing and abrasion.

Factors Affecting Yarn Strength

Yarn strength depends on fiber quality, twist level, and spinning method, directly influencing fabric durability and performance. Fiber type, length, and uniformity play a crucial role in determining yarn tensile strength, while higher twist increases yarn cohesion but may reduce flexibility. Understanding these factors helps you optimize fabric strength for specific textile applications by selecting the appropriate yarn characteristics.

Elements Influencing Fabric Strength

Fabric strength is primarily influenced by the tensile strength and elongation properties of the yarns used in weaving or knitting. Factors such as fiber type, yarn twist, yarn count, and yarn uniformity significantly impact how the individual yarns interlock and distribute stress throughout the fabric. Additionally, weave tightness and fabric construction methods determine load distribution, contributing to the overall durability and resistance to tearing or abrasion in finished textiles.

Relationship Between Yarn Strength and Fabric Strength

Yarn strength directly influences fabric strength because stronger yarns provide better resistance to tension and tearing, resulting in more durable textiles. Fabric strength depends on yarn strength, yarn twist, and fabric construction factors like weave or knit tightness, which collectively determine the final material performance. Understanding this relationship helps you select appropriate yarns for fabrics designed to withstand specific stress and usage conditions.

Testing Methods for Yarn and Fabric Strength

Tensile testing machines measure yarn strength by applying controlled tension until the fiber breaks, providing data on tensile strength, elongation, and breaking force. Fabric strength is often assessed using methods like the grab test, tongue tear test, or bursting strength test, which evaluate resistance to different forces and simulate real-world wear conditions. Understanding both yarn and fabric strength testing results helps you optimize material selection for durability and performance in textile applications.

Importance of Yarn Strength in Textile Manufacturing

Yarn strength is a critical factor in textile manufacturing as it directly influences the durability and quality of the final fabric. Strong yarns withstand the stresses of weaving and knitting processes, reducing breakage and production downtime. Consequently, fabric strength largely depends on the tensile properties of the constituent yarns, making yarn strength essential for ensuring high-performance, long-lasting textiles.

Impact of Fabric Structure on Overall Strength

Fabric structure significantly influences overall fabric strength by determining how yarns interact and distribute stress under tension. Tight weaves like satin and twill enhance strength by increasing yarn interlacing, while looser weaves reduce fabric durability despite high yarn strength. Your fabric's performance depends on both yarn tensile properties and the structural design that governs load transfer and resistance to tearing.

Practical Applications: Selecting the Right Strength for End Use

Yarn strength directly impacts fabric durability, with high-strength yarns essential for heavy-duty applications like industrial workwear and outdoor gear, ensuring longevity under stress. Fabric strength depends not only on yarn quality but also on weave construction and finishing processes, influencing performance in applications such as upholstery or sportswear. Your choice of yarn and fabric strength should align with the specific end use, balancing flexibility, abrasion resistance, and load-bearing capacity to optimize product performance and lifespan.

Yarn strength vs Fabric strength Infographic

libmatt.com

libmatt.com