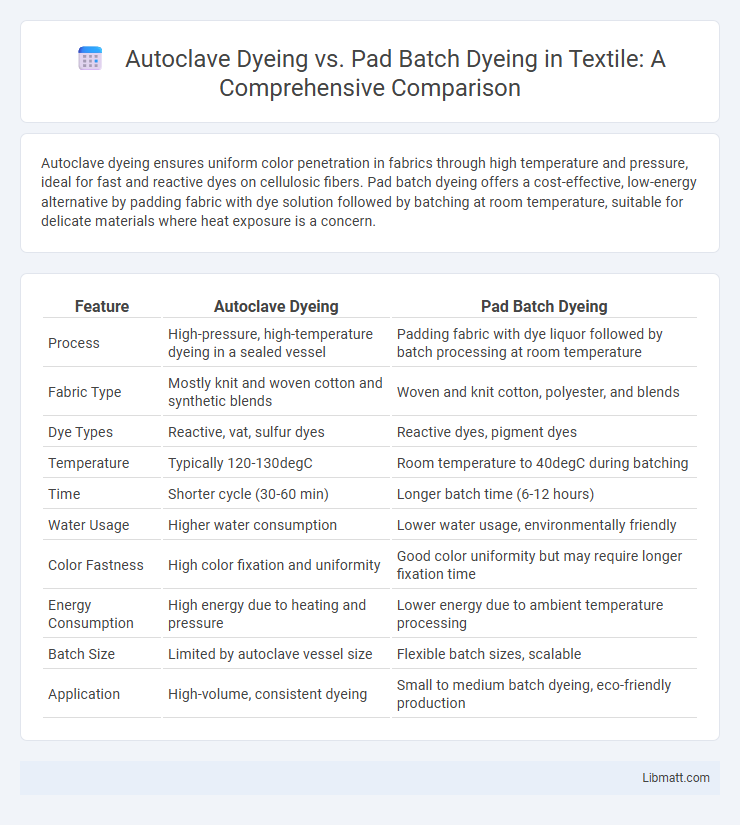

Autoclave dyeing ensures uniform color penetration in fabrics through high temperature and pressure, ideal for fast and reactive dyes on cellulosic fibers. Pad batch dyeing offers a cost-effective, low-energy alternative by padding fabric with dye solution followed by batching at room temperature, suitable for delicate materials where heat exposure is a concern.

Table of Comparison

| Feature | Autoclave Dyeing | Pad Batch Dyeing |

|---|---|---|

| Process | High-pressure, high-temperature dyeing in a sealed vessel | Padding fabric with dye liquor followed by batch processing at room temperature |

| Fabric Type | Mostly knit and woven cotton and synthetic blends | Woven and knit cotton, polyester, and blends |

| Dye Types | Reactive, vat, sulfur dyes | Reactive dyes, pigment dyes |

| Temperature | Typically 120-130degC | Room temperature to 40degC during batching |

| Time | Shorter cycle (30-60 min) | Longer batch time (6-12 hours) |

| Water Usage | Higher water consumption | Lower water usage, environmentally friendly |

| Color Fastness | High color fixation and uniformity | Good color uniformity but may require longer fixation time |

| Energy Consumption | High energy due to heating and pressure | Lower energy due to ambient temperature processing |

| Batch Size | Limited by autoclave vessel size | Flexible batch sizes, scalable |

| Application | High-volume, consistent dyeing | Small to medium batch dyeing, eco-friendly production |

Introduction to Autoclave and Pad Batch Dyeing

Autoclave dyeing uses pressurized vessels to achieve high-temperature dyeing, ensuring uniform color penetration and reduced processing time for textile fibers. Pad batch dyeing involves passing fabric through dye liquor and then resting for an extended period to develop color intensity without heat, ideal for delicate materials and energy savings. Your choice depends on fabric type, desired colorfastness, and production scale, as autoclave suits bulk processing while pad batch offers gentle, eco-friendly dye application.

Overview of the Dyeing Processes

Autoclave dyeing involves high-pressure and temperature conditions to ensure deep penetration of dye into fibers, making it suitable for synthetic and blended fabrics. Pad batch dyeing uses a padding mangle to impregnate fabric with dye at room temperature, followed by a resting period, ideal for delicate materials and cellulosic fibers. Your choice between these methods depends on fabric type, dye affinity, and production scale requirements.

Equipment and Technology Used

Autoclave dyeing utilizes a sealed pressure vessel equipped with precise temperature and pressure controls to ensure even dye penetration, making it ideal for batch processing of woven and knitted fabrics. Pad batch dyeing employs padding mangle machines that impregnate fabric with dye solutions followed by batch resting, relying on lower energy consumption and simpler technology compared to autoclaves. Your choice between these methods depends on fabric type, production scale, and equipment investment considerations linked to autoclave reactors versus padding mangle systems.

Process Time and Efficiency Comparison

Autoclave dyeing typically requires high-temperature and high-pressure conditions, resulting in process times ranging from 30 to 60 minutes, which enables rapid dye fixation and uniform color penetration. Pad batch dyeing operates at ambient or slightly elevated temperatures, requiring longer process times of 6 to 12 hours for effective dye fixation, but offers greater energy efficiency and lower equipment costs. In terms of efficiency, autoclave dyeing offers faster throughput and better control over dye uniformity, whereas pad batch dyeing excels in energy savings and simpler operational requirements, making each suitable for different production scales and fabric types.

Dye Penetration and Color Uniformity

Autoclave dyeing ensures deep dye penetration through high-temperature and pressure conditions, resulting in superior color uniformity across fabric surfaces. Pad batch dyeing relies on sustained diffusion at ambient or moderate temperatures, which may lead to less consistent dye uptake and slight variations in color tone. Your choice between these methods depends on the fabric type and desired uniformity, with autoclave dyeing offering more reliable and even coloration.

Energy Consumption and Environmental Impact

Autoclave dyeing consumes significantly more energy due to high temperature and pressure requirements, increasing its environmental footprint through elevated greenhouse gas emissions. In contrast, pad batch dyeing operates at ambient temperatures, resulting in lower energy usage and reduced carbon emissions, making it a more sustainable option. Wastewater generated from autoclave dyeing contains higher concentrations of chemicals and dyes, further intensifying environmental pollution compared to the milder effluents from pad batch processes.

Cost Analysis: Autoclave vs Pad Batch

Autoclave dyeing generally involves higher initial capital investment and operational costs due to energy consumption and sophisticated machinery, making it suitable for medium to large-scale production. Pad batch dyeing offers lower operational costs and reduced energy usage, optimal for small to medium quantities with extended dye fixation times compensating for lower temperature processes. Cost analysis reveals pad batch dyeing as more cost-effective for batch sizes with flexible timelines, while autoclave dyeing benefits bulk production demanding rapid processing and higher precision.

Fabric Types Suitable for Each Method

Autoclave dyeing is ideal for knit fabrics, particularly synthetic fibers like polyester and nylon, due to its high-temperature and pressure conditions that ensure deep dye penetration and consistent color. Pad batch dyeing suits woven fabrics made from natural fibers such as cotton and linen, as it operates at room temperature and relies on prolonged fixation time, which is gentler on delicate textiles. Your choice between these methods should align with the fabric's fiber composition and desired colorfastness to achieve optimal dyeing results.

Quality Control and Consistency

Autoclave dyeing offers superior quality control through precise temperature and pressure regulation, resulting in uniform dye penetration and consistent fabric color. Pad batch dyeing relies on controlled dwell time and pad pressure, ensuring even dye application but may exhibit slight variations in color intensity across batches. Both methods provide reliable consistency, with autoclave dyeing favored for high-volume production requiring stringent quality standards.

Choosing the Right Dyeing Method

Selecting the right dyeing method depends on fabric type, production scale, and colorfastness requirements; autoclave dyeing excels in achieving uniform deep shades on durable fabrics like cotton under high-pressure steam conditions. Pad batch dyeing suits delicate or sensitive textiles such as silk and polyester blends, offering low-temperature, energy-efficient processing with minimal fabric distortion. Evaluating factors like fabric composition, desired color intensity, and environmental impact ensures optimal dyeing performance and sustainable textile finishing.

Autoclave dyeing vs Pad batch dyeing Infographic

libmatt.com

libmatt.com