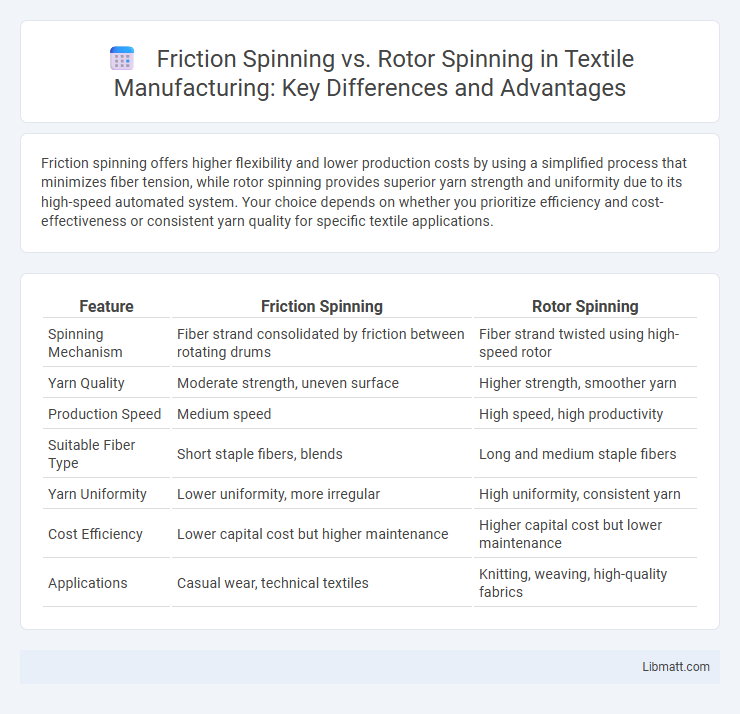

Friction spinning offers higher flexibility and lower production costs by using a simplified process that minimizes fiber tension, while rotor spinning provides superior yarn strength and uniformity due to its high-speed automated system. Your choice depends on whether you prioritize efficiency and cost-effectiveness or consistent yarn quality for specific textile applications.

Table of Comparison

| Feature | Friction Spinning | Rotor Spinning |

|---|---|---|

| Spinning Mechanism | Fiber strand consolidated by friction between rotating drums | Fiber strand twisted using high-speed rotor |

| Yarn Quality | Moderate strength, uneven surface | Higher strength, smoother yarn |

| Production Speed | Medium speed | High speed, high productivity |

| Suitable Fiber Type | Short staple fibers, blends | Long and medium staple fibers |

| Yarn Uniformity | Lower uniformity, more irregular | High uniformity, consistent yarn |

| Cost Efficiency | Lower capital cost but higher maintenance | Higher capital cost but lower maintenance |

| Applications | Casual wear, technical textiles | Knitting, weaving, high-quality fabrics |

Introduction to Friction Spinning and Rotor Spinning

Friction spinning uses high-speed rotating drums to twist fibers into yarn by frictional forces, producing yarns with high bulk and strength suitable for heavy-duty textiles. Rotor spinning, also known as open-end spinning, involves feeding fibers into a rapidly rotating rotor where they are drawn out and twisted to form yarn, offering higher production speeds and cost efficiency for medium to coarse yarns. Both techniques contrast with traditional ring spinning by eliminating the spindle, resulting in varying yarn properties and manufacturing applications.

Historical Development of Spinning Technologies

Friction spinning emerged in the mid-20th century as an innovative method designed to produce yarns with higher bulk and improved uniformity compared to traditional rotor spinning, which dates back to the early 20th century and revolutionized spinning with its high-speed, centrifugal process. Rotor spinning's development marked a significant shift from ring spinning by enabling faster production rates and reduced labor costs, while friction spinning introduced unique fiber entanglement through friction forces, catering to specialty yarn markets. The historical evolution of these technologies reflects the textile industry's ongoing pursuit of efficiency, yarn quality, and adaptability to diverse fiber types and end-use applications.

Principle and Process of Friction Spinning

Friction spinning operates by feeding fiber tufts onto a rotating drum where friction forces twist and bind the fibers into yarn, enabling rapid production of coarse and bulky yarns ideal for technical textiles. The process involves simultaneous fiber feeding and twisting without the need for a spindle, distinguishing it from rotor spinning, which utilizes a rotating rotor to insert twist into the fiber strand. Understanding the principle of friction spinning can help you select the optimal spinning method for applications requiring high-speed yarn formation and textured yarn characteristics.

Principle and Process of Rotor Spinning

Rotor spinning operates on the principle of using a high-speed rotating open rotor to twist and insert the yarn twist simultaneously while fibers are fed into the rotor chamber. During the process, fibers are continuously fed through a carding system and pneumatically transported into the rotor, where centrifugal force aligns and twists them into yarn. This method enables high production speeds and is well-suited for spinning coarse and medium counts with improved yarn uniformity and tensile strength.

Key Differences Between Friction and Rotor Spinning

Friction spinning utilizes frictional forces between rotating drums to wrap fibers around a core, producing yarn with high bulk and excellent stretch properties, while rotor spinning incorporates centrifugal force inside a rotating rotor to draft and twist fibers into yarn, resulting in higher productivity and more uniform yarn strength. Friction spinning excels in spinning short-staple fibers and creating textured yarns with good elasticity, whereas rotor spinning is preferred for longer staple fibers and produces smoother, more consistent yarn suitable for a wide range of textile applications. The key differences lie in their mechanisms of fiber integration, yarn characteristics, and suitability for specific fiber types and end-use requirements.

Yarn Structure and Properties Comparison

Friction spinning produces yarn with a core-sheath structure, where the sheath fibers are wrapped around the core, resulting in higher bulkiness and better cover factor compared to rotor spinning, which forms yarn by condensing fibers through centrifugal force, producing more uniform and finer yarn. Yarn from friction spinning exhibits increased hairiness and lower twist, enhancing softness but reducing tensile strength relative to rotor-spun yarn, known for higher strength and lower hairiness due to its compact fiber arrangement. These structural differences make friction-spun yarns suitable for textured, bulky fabrics, while rotor-spun yarns serve applications requiring strength and smooth surface appearance.

Advantages of Friction Spinning

Friction spinning offers faster production speeds and greater flexibility in fiber blend ratios compared to rotor spinning, enabling more efficient manufacturing of specialty yarns. It produces yarns with superior bulk and softness, ideal for knitwear and textured fabrics, enhancing fabric comfort and aesthetics. The process also allows for lower energy consumption and reduced waste, contributing to cost-effective and sustainable textile production.

Advantages of Rotor Spinning

Rotor spinning offers higher production speeds and greater yarn uniformity compared to friction spinning, making it ideal for large-scale textile manufacturing. The process reduces yarn hairiness, resulting in smoother fabrics with improved strength and durability. Your choice of rotor spinning can enhance efficiency and product quality in high-volume yarn production.

Applications in the Textile Industry

Friction spinning excels in producing bulky yarns ideal for home textiles, upholstery, and carpet manufacturing due to its ability to handle coarse and multi-component fibers efficiently. Rotor spinning offers higher production speeds and consistent quality, making it preferable for mass-producing fine and medium yarns used in apparel and industrial fabrics. Your choice between friction and rotor spinning depends on the desired fabric texture, fiber type, and end-use application within the textile industry.

Future Trends in Spinning Technologies

Friction spinning is expected to advance with innovations in fiber blending and automation, offering enhanced yarn uniformity and eco-friendly processing. Rotor spinning continues to evolve by integrating high-speed rotors and digital monitoring systems that improve productivity and reduce waste. Both technologies are converging towards sustainable manufacturing with smart sensors and AI-driven quality control shaping the future of yarn production.

Friction Spinning vs Rotor Spinning Infographic

libmatt.com

libmatt.com