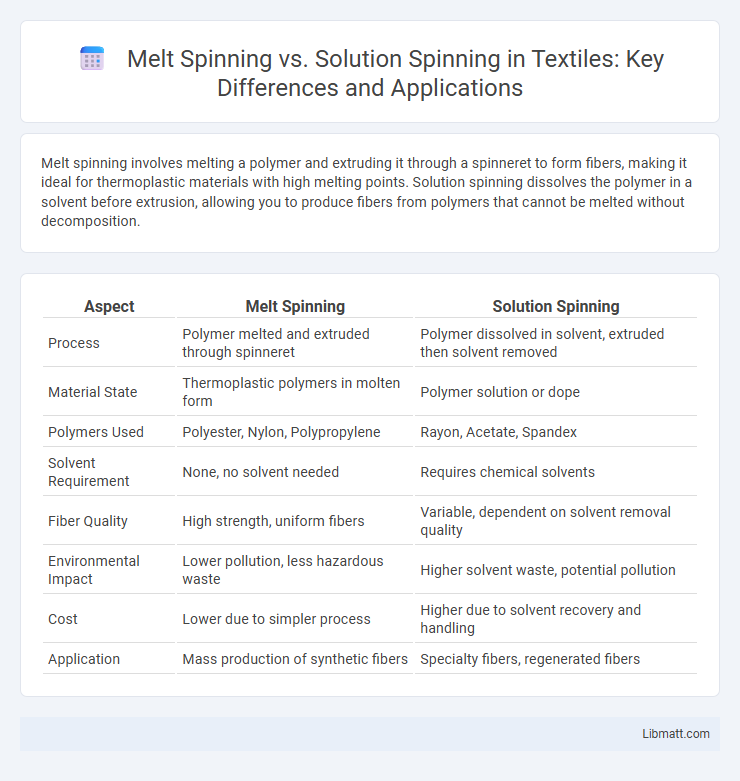

Melt spinning involves melting a polymer and extruding it through a spinneret to form fibers, making it ideal for thermoplastic materials with high melting points. Solution spinning dissolves the polymer in a solvent before extrusion, allowing you to produce fibers from polymers that cannot be melted without decomposition.

Table of Comparison

| Aspect | Melt Spinning | Solution Spinning |

|---|---|---|

| Process | Polymer melted and extruded through spinneret | Polymer dissolved in solvent, extruded then solvent removed |

| Material State | Thermoplastic polymers in molten form | Polymer solution or dope |

| Polymers Used | Polyester, Nylon, Polypropylene | Rayon, Acetate, Spandex |

| Solvent Requirement | None, no solvent needed | Requires chemical solvents |

| Fiber Quality | High strength, uniform fibers | Variable, dependent on solvent removal quality |

| Environmental Impact | Lower pollution, less hazardous waste | Higher solvent waste, potential pollution |

| Cost | Lower due to simpler process | Higher due to solvent recovery and handling |

| Application | Mass production of synthetic fibers | Specialty fibers, regenerated fibers |

Introduction to Melt Spinning and Solution Spinning

Melt spinning involves melting a polymer and extruding it through a spinneret to form fibers, which rapidly cool and solidify, making it ideal for thermoplastic polymers like nylon and polyester. Solution spinning dissolves polymers in a solvent before extrusion, followed by solvent evaporation or coagulation to form fibers, suitable for polymers that degrade at high temperatures such as aramid and cellulose. Understanding the differences in these processes helps you select the appropriate fiber production method based on polymer properties and desired fiber characteristics.

Overview of Fiber Spinning Technologies

Melt spinning involves melting a polymer and extruding it through a spinneret to form fibers, ideal for thermoplastics like polyester and nylon due to its high production speed and cost-effectiveness. Solution spinning, including wet and dry spinning, dissolves polymers in solvents and extrudes them to form fibers, suitable for polymers that degrade at high temperatures, such as acrylic and rayon, offering finer control over fiber morphology. These spinning technologies are fundamental to textile manufacturing, influencing fiber properties like strength, elasticity, and durability based on polymer type and processing conditions.

Principles of Melt Spinning

Melt spinning involves melting a polymer and extruding it through a spinneret to form fibers as the material cools and solidifies, relying on thermal processes without solvents. The polymer's viscosity and cooling rate critically affect fiber formation and properties, making melt spinning efficient for thermoplastic polymers. You can achieve high production rates and consistent filament quality due to its solvent-free, continuous processing method.

Principles of Solution Spinning

Solution spinning relies on dissolving polymers into a suitable solvent to create a viscous solution, which is then extruded through a spinneret into a coagulation bath or evaporative environment to form continuous fibers. This method allows precise control over fiber diameter, morphology, and properties by adjusting parameters such as polymer concentration, solvent type, and spinning conditions. Your choice of solution spinning can significantly influence fiber uniformity and mechanical performance, making it ideal for producing specialized synthetic and natural polymer fibers.

Key Materials Used in Melt vs Solution Spinning

Melt spinning primarily uses thermoplastic polymers such as nylon, polyester, and polypropylene, which can be melted and solidified to form fibers. Solution spinning utilizes polymers dissolved in a solvent, with common materials including cellulose acetate, polyacrylonitrile (PAN), and aramid fibers, enabling the production of fibers that do not melt easily. You should choose the spinning method based on the polymer's thermal properties and solubility to optimize fiber quality and application.

Process Steps: Melt Spinning vs Solution Spinning

Melt spinning involves melting a polymer and extruding it through a spinneret into cool air, where the filament solidifies rapidly. Solution spinning dissolves the polymer in a solvent to create a viscous solution that is extruded through a spinneret, followed by coagulation or evaporation steps to solidify the fiber. Key differences lie in melt spinning eliminating solvents, relying on thermal solidification, while solution spinning requires solvent removal either by evaporation (dry spinning) or coagulation (wet spinning).

Advantages of Melt Spinning

Melt spinning offers significant advantages such as faster production speeds and the elimination of solvents, making it more environmentally friendly and cost-effective than solution spinning. It enables the creation of uniform fibers with high tensile strength due to precise control over cooling rates and fiber formation. Your manufacturing process benefits from reduced chemical handling and improved scalability when choosing melt spinning for fiber production.

Advantages of Solution Spinning

Solution spinning offers superior control over fiber morphology and diameter, enabling the production of ultra-fine and uniform fibers critical for high-performance applications. It allows the processing of polymers with high melting points or those that degrade upon heating, expanding the range of materials available for fiber production. Your ability to tailor fiber properties through solution spinning enhances material functionality in industries like filtration, medical textiles, and composites.

Challenges and Limitations of Both Methods

Melt spinning faces challenges such as high energy consumption due to the need for melting polymers at elevated temperatures and limitations in processing heat-sensitive materials, which can degrade under intense heat. Solution spinning encounters issues with solvent recovery and environmental concerns, alongside slower production rates and potential fiber contamination from residual solvents. Your choice between these methods must consider these constraints to balance efficiency, material compatibility, and environmental impact.

Applications and Industry Use Cases

Melt spinning is primarily used in the production of synthetic fibers like polyester and nylon, widely applied in textiles, automotive components, and industrial filtration due to its high-speed fiber formation and cost efficiency. Solution spinning, including wet and dry spinning, is essential for manufacturing specialty fibers such as aramid, spandex, and carbon fibers, catering to high-performance applications in aerospace, medical textiles, and protective clothing. Both techniques play crucial roles in advanced material manufacturing, with melt spinning dominating commodity fiber markets and solution spinning addressing niche markets requiring enhanced fiber properties.

Melt spinning vs Solution spinning Infographic

libmatt.com

libmatt.com