An overlock machine sews over the edge of fabric to prevent fraying, creating strong, professional seams ideal for stretch fabrics and garment construction. Your choice depends on whether you need secure edge finishing (overlock) or decorative, flat seams that lie smooth on both sides (flatlock).

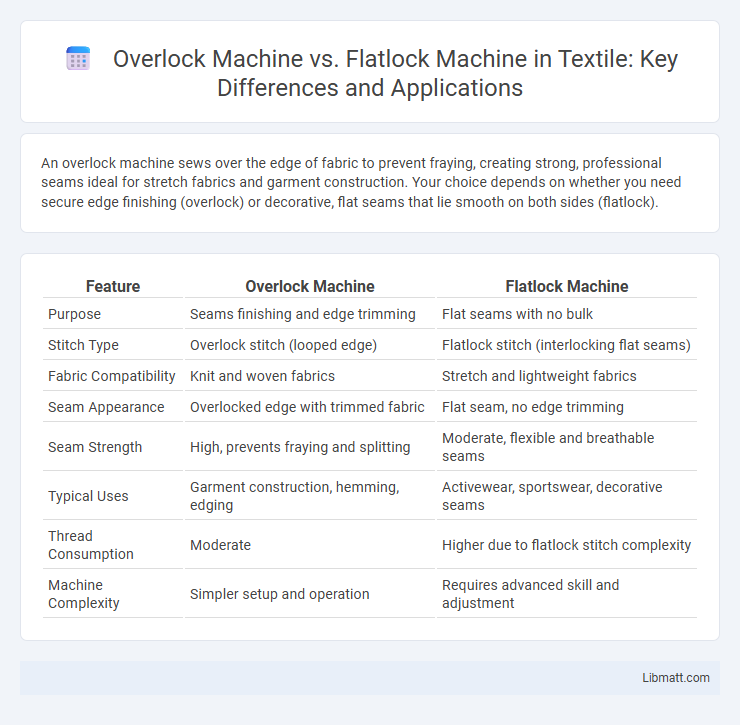

Table of Comparison

| Feature | Overlock Machine | Flatlock Machine |

|---|---|---|

| Purpose | Seams finishing and edge trimming | Flat seams with no bulk |

| Stitch Type | Overlock stitch (looped edge) | Flatlock stitch (interlocking flat seams) |

| Fabric Compatibility | Knit and woven fabrics | Stretch and lightweight fabrics |

| Seam Appearance | Overlocked edge with trimmed fabric | Flat seam, no edge trimming |

| Seam Strength | High, prevents fraying and splitting | Moderate, flexible and breathable seams |

| Typical Uses | Garment construction, hemming, edging | Activewear, sportswear, decorative seams |

| Thread Consumption | Moderate | Higher due to flatlock stitch complexity |

| Machine Complexity | Simpler setup and operation | Requires advanced skill and adjustment |

Introduction to Overlock and Flatlock Machines

Overlock machines specialize in stitching edges with multiple threads to prevent fabric fraying and create durable seams, making them essential for professional garment finishing. Flatlock machines, on the other hand, produce flat seams by overlapping fabric edges and stitching them together, commonly used in activewear and stretchy fabrics for comfort and flexibility. Understanding these machines' functions helps you choose the right equipment for precise seam types and fabric applications.

Key Differences Between Overlock and Flatlock Machines

Overlock machines specialize in edging fabric with strong, neat stitches ideal for preventing fraying, using multiple threads and loopers for durability and elasticity. Flatlock machines create flat seams by joining fabric edges with a stitch that lies flat on both sides, making them perfect for visible seams in sportswear and activewear. Understanding these key differences helps you choose the right machine for your sewing project, whether it's finishing raw edges or creating decorative, flat seams.

How Overlock Machines Work

Overlock machines use multiple threads and loopers to stitch over the edge of fabric, preventing fraying and creating a clean, durable seam ideal for knit and stretch fabrics. These machines simultaneously trim excess fabric while sewing, ensuring precise seam finishes and efficient production. Typically equipped with 3 to 5 threads, overlock machines provide elasticity and strong seam construction for garment manufacturing.

How Flatlock Machines Function

Flatlock machines create strong, flat seams by feeding two fabric edges together and stitching them with multiple needle threads that interlock on the underside, eliminating bulk and creating a smooth finish ideal for activewear and stretch fabrics. Unlike overlock machines that trim fabric edges while sewing, flatlock machines focus on joining fabrics edge-to-edge without trimming, allowing for reversible seams and greater flexibility. Your choice of a flatlock machine supports projects requiring durable, flat seams that enhance comfort and garment aesthetics.

Stitch Types: Overlock vs Flatlock

Overlock machines create strong, durable stitches by simultaneously trimming fabric edges and encasing them with thread, ideal for preventing fraying on seams. Flatlock machines produce flat seams by joining fabric edges with decorative, stretchable stitches that lie flat against the material, perfect for sportswear and activewear. Your choice depends on whether you need seam finishing strength or a smooth, flexible seam appearance.

Applications and Uses of Overlock Machines

Overlock machines are primarily used for finishing seams, trimming excess fabric, and preventing fraying in garment production, making them essential in mass apparel manufacturing and textile finishing. They excel in creating strong, stretchable seams ideal for knitwear, activewear, and lingerie that require elasticity and durability. Their ability to sew multiple threads simultaneously enhances productivity and seam quality compared to flatlock machines, which are better suited for decorative stitching and flat seams.

Applications and Uses of Flatlock Machines

Flatlock machines are primarily used for creating flat seams ideal for activewear, lingerie, and swimwear, where comfort and stretch are essential. These machines produce decorative or functional seams that lie flat against the fabric, reducing bulk and enhancing garment flexibility. You will find flatlock stitching beneficial for sportswear and seamless clothing designs due to its durability and smooth finish.

Pros and Cons: Overlock Machines

Overlock machines excel at creating strong, stretchy seams and finishing edges quickly, making them ideal for sewing knit fabrics and preventing fraying. Their main drawbacks include limited stitch variety and a learning curve for threading multiple threads correctly. Your sewing projects benefit from the overlock machine's speed and durability, but you may require a flatlock machine for decorative flat seams and wider stitch options.

Pros and Cons: Flatlock Machines

Flatlock machines offer excellent stitch strength and a clean finish ideal for activewear, but they are limited in fabric versatility, performing best on knit materials. They allow flat seams that reduce bulk and prevent chafing, enhancing garment comfort, yet their slower stitching speed may hinder mass production efficiency. Compared to overlock machines, flatlock machines lack seam trimming capabilities, requiring additional finishing steps.

Choosing the Right Machine for Your Sewing Needs

Overlock machines specialize in sewing seams, trimming fabric edges, and preventing fraying, making them ideal for finishing knit and woven fabrics with strong, elastic stitches. Flatlock machines create flat, seam-like joins without bulk, perfect for activewear, stretch fabrics, and decorative topstitching where comfort and minimal seam thickness are essential. Your choice should depend on whether you prioritize durable seam finishing with an overlocker or smooth, flat seams using a flatlock machine for your specific sewing projects.

Overlock machine vs Flatlock machine Infographic

libmatt.com

libmatt.com