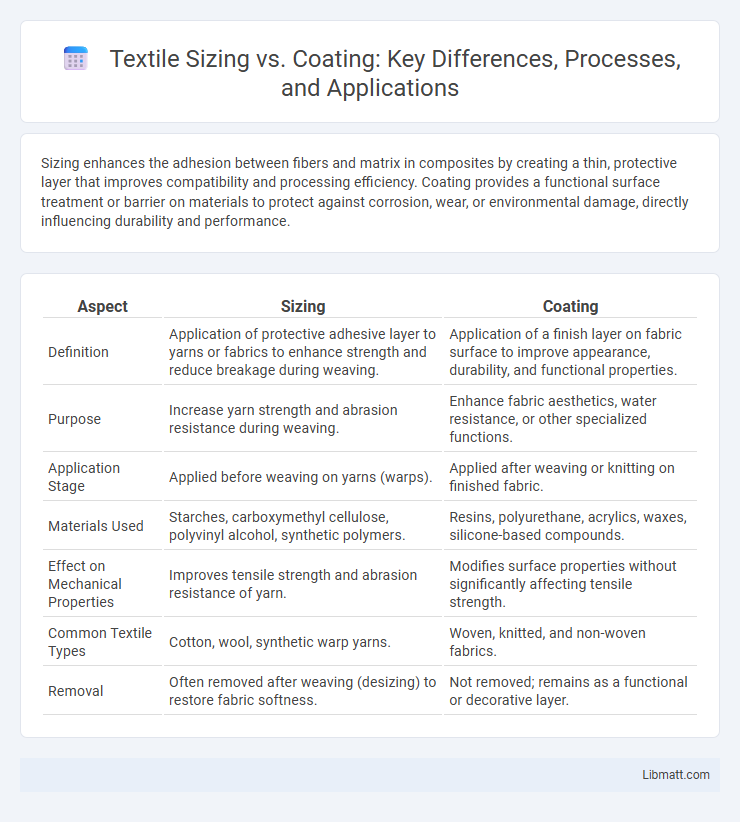

Sizing enhances the adhesion between fibers and matrix in composites by creating a thin, protective layer that improves compatibility and processing efficiency. Coating provides a functional surface treatment or barrier on materials to protect against corrosion, wear, or environmental damage, directly influencing durability and performance.

Table of Comparison

| Aspect | Sizing | Coating |

|---|---|---|

| Definition | Application of protective adhesive layer to yarns or fabrics to enhance strength and reduce breakage during weaving. | Application of a finish layer on fabric surface to improve appearance, durability, and functional properties. |

| Purpose | Increase yarn strength and abrasion resistance during weaving. | Enhance fabric aesthetics, water resistance, or other specialized functions. |

| Application Stage | Applied before weaving on yarns (warps). | Applied after weaving or knitting on finished fabric. |

| Materials Used | Starches, carboxymethyl cellulose, polyvinyl alcohol, synthetic polymers. | Resins, polyurethane, acrylics, waxes, silicone-based compounds. |

| Effect on Mechanical Properties | Improves tensile strength and abrasion resistance of yarn. | Modifies surface properties without significantly affecting tensile strength. |

| Common Textile Types | Cotton, wool, synthetic warp yarns. | Woven, knitted, and non-woven fabrics. |

| Removal | Often removed after weaving (desizing) to restore fabric softness. | Not removed; remains as a functional or decorative layer. |

Introduction to Sizing and Coating

Sizing and coating are essential processes in papermaking that enhance the paper's surface properties and durability. Sizing involves applying a substance to paper fibers to reduce absorbency and improve printability, while coating adds a layer on the surface to enhance smoothness, brightness, and barrier properties. Understanding the differences between sizing and coating helps you select the right paper quality for your specific printing or packaging needs.

Definitions: What is Sizing vs. Coating?

Sizing is a chemical treatment applied to fibers or materials to improve adhesion, control absorbency, and enhance strength during processing. Coating refers to the application of a layer of material on a substrate's surface to provide protection, improve appearance, or impart functional properties like water resistance or durability. While sizing primarily modifies internal fiber characteristics, coating mainly affects surface properties.

Key Differences Between Sizing and Coating

Sizing involves applying a thin adhesive layer to fibers or paper surfaces to enhance strength and reduce absorbency, improving printability and durability. Coating adds a thicker, often pigmented layer to the material's surface, enhancing gloss, smoothness, and visual appeal while also providing barrier properties. The main difference lies in sizing's function to modify internal fiber interactions and coating's role in altering surface characteristics for aesthetic and protective purposes.

Functions and Purposes of Sizing

Sizing primarily enhances fiber adhesion, improving the bonding between the fiber and the resin matrix in composite materials, which is crucial for mechanical strength and durability. It also protects fibers from damage during handling and processing, reducing breakage and maintaining fiber integrity. Your choice of sizing directly impacts the performance, longevity, and quality of the final composite product.

Functions and Purposes of Coating

Coating on paper primarily enhances surface properties such as smoothness, gloss, and printability, enabling sharper images and vibrant colors. It serves as a protective barrier against moisture, dirt, and wear, extending the paper's durability and usability in various applications. Your choice of coating directly influences the final aesthetic and functional quality of printed materials, distinguishing it from sizing which mainly controls absorbency.

Common Materials Used in Sizing and Coating

Common materials used in sizing include starches, polyvinyl alcohol, and alkyl ketene dimer (AKD), which enhance fiber bonding and surface strength of paper products. Coating materials often consist of pigments like calcium carbonate, kaolin clay, and titanium dioxide combined with binders such as latex or starch to improve gloss, brightness, and printability. Selecting the right combination of sizing and coating materials ensures your paper meets desired performance and aesthetic standards.

Applications in Paper and Textile Industries

Sizing enhances paper and textile products by improving surface strength, water resistance, and printability, essential for high-quality printing and durability. Coating provides a protective layer that enhances gloss, smoothness, and resistance to wear, crucial in packaging and decorative textiles. Both processes are extensively used in the paper industry for improved printing surfaces and in textiles to achieve functional finishes like water repellency and abrasion resistance.

Performance Impact: Sizing vs. Coating

Sizing enhances fiber-matrix adhesion in composites by providing a chemical bond and improving wetting properties, directly impacting mechanical strength and durability. Coating primarily adds functional properties such as corrosion resistance, electrical conductivity, or UV protection without significantly altering the fiber's tensile strength. The performance impact of sizing is critical for structural integrity, whereas coating optimizes surface characteristics for specific environmental or application needs.

Environmental Considerations

Sizing and coating both impact environmental sustainability, with natural and biodegradable sizing agents reducing ecological footprints compared to synthetic coatings that may contain volatile organic compounds (VOCs). Your choice should consider life cycle assessments, including raw material sourcing, production emissions, and end-of-life disposal or recyclability. Opting for eco-friendly sizing can minimize pollution and promote sustainable paper and textile manufacturing processes.

Conclusion: Choosing Between Sizing and Coating

Selecting between sizing and coating depends on the intended application and desired material properties, where sizing primarily enhances fiber-matrix adhesion in composites, and coating provides surface protection and functional features such as hydrophobicity or UV resistance. Sizing typically improves mechanical strength and durability of composites, while coatings offer customizable surface characteristics critical for wear resistance or aesthetic purposes. Evaluating the specific performance requirements and environmental exposure conditions guides the optimal choice between these two surface treatment methods.

Sizing vs Coating Infographic

libmatt.com

libmatt.com