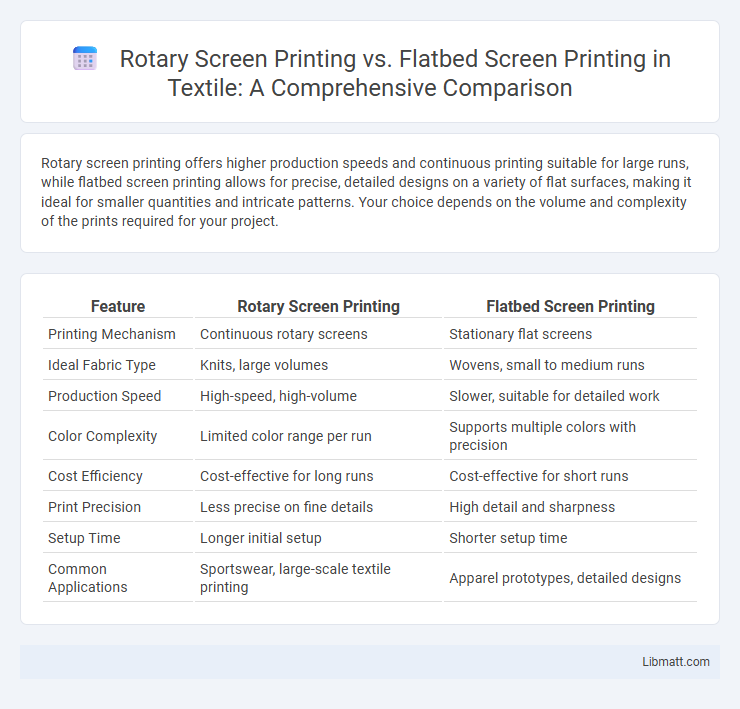

Rotary screen printing offers higher production speeds and continuous printing suitable for large runs, while flatbed screen printing allows for precise, detailed designs on a variety of flat surfaces, making it ideal for smaller quantities and intricate patterns. Your choice depends on the volume and complexity of the prints required for your project.

Table of Comparison

| Feature | Rotary Screen Printing | Flatbed Screen Printing |

|---|---|---|

| Printing Mechanism | Continuous rotary screens | Stationary flat screens |

| Ideal Fabric Type | Knits, large volumes | Wovens, small to medium runs |

| Production Speed | High-speed, high-volume | Slower, suitable for detailed work |

| Color Complexity | Limited color range per run | Supports multiple colors with precision |

| Cost Efficiency | Cost-effective for long runs | Cost-effective for short runs |

| Print Precision | Less precise on fine details | High detail and sharpness |

| Setup Time | Longer initial setup | Shorter setup time |

| Common Applications | Sportswear, large-scale textile printing | Apparel prototypes, detailed designs |

Overview of Rotary Screen Printing

Rotary screen printing uses cylindrical screens that rotate continuously to apply designs, enabling high-speed production and efficient printing on long fabric rolls. This method excels in large-scale manufacturing, offering consistent print quality and reduced setup times compared to flatbed screen printing. Your choice of rotary screen printing is ideal for seamless patterns and mass production in textile industries.

Overview of Flatbed Screen Printing

Flatbed screen printing uses a stationary flat screen through which ink is pressed onto a substrate, ideal for precise, high-detail designs on rigid or flat materials. This technique supports high-resolution prints on items like circuit boards, glass panels, and signage, with excellent color accuracy and layering capabilities. Its slower production speed compared to rotary screen printing makes it suitable for short runs and customized prints.

Key Differences Between Rotary and Flatbed Screen Printing

Rotary screen printing uses cylindrical screens that rotate continuously, making it ideal for high-speed production on textiles and long fabric runs. Flatbed screen printing employs stationary flat screens pressing ink through mesh onto flat surfaces, offering precise detail and is best suited for short runs or multi-color designs. The primary difference lies in the printing method and speed, where rotary excels in efficiency for continuous patterns, and flatbed provides superior accuracy and versatility for complex, multi-layer prints.

Printing Speed and Production Efficiency

Rotary screen printing offers significantly higher printing speeds, reaching up to 100 meters per minute, making it ideal for large-volume production runs. Flatbed screen printing operates at slower speeds, typically around 5-10 meters per minute, but provides greater precision for detailed designs. Your choice depends on balancing the need for rapid output with the desired print quality and complexity.

Design Capabilities and Flexibility

Rotary screen printing excels in high-speed production of continuous patterns and complex color gradients, offering superior design flexibility for large-scale textile printing. Flatbed screen printing provides precise control over intricate, multi-color designs on various materials, making it ideal for detailed artwork and smaller production runs. Your choice between these methods should consider the complexity of your design and the production volume required.

Suitable Fabrics and Materials

Rotary screen printing excels with continuous fabric printing, making it ideal for lightweight to medium-weight textiles such as cotton, polyester, and blends commonly used in fashion and home decor. Flatbed screen printing suits heavier or more rigid fabrics like denim, leather, and canvas, offering precise and detailed prints with shorter runs and varied designs. Both methods accommodate dyes and inks for natural and synthetic fibers, but rotary printing favors high-volume production on smooth, flexible materials.

Print Quality and Precision Comparison

Rotary screen printing excels in high-speed production with consistent print quality on cylindrical or continuous materials, offering precise registration for detailed designs over long runs. Flatbed screen printing delivers superior print precision for intricate and multi-color patterns on flat surfaces, ensuring sharp edges and vivid colors with better control over ink deposition. Your choice depends on the substrate and detail level, as flatbed printing provides enhanced accuracy for complex graphics, while rotary printing balances speed with acceptable quality for simpler designs.

Setup, Operation, and Maintenance

Rotary screen printing features continuous cylindrical screens enabling high-speed production with minimal setup time, while flatbed screen printing uses stationary flat screens requiring longer setup and alignment processes. Operation of rotary systems is automated, providing consistent ink application suitable for large runs, whereas flatbed printing often involves manual or semi-automated steps, ideal for short runs and detailed designs. Maintenance of rotary screens demands precise cleaning to avoid screen clogging and frequent inspection of cylinders, whereas flatbed screens require thorough cleaning of mesh and frames, with simpler repair procedures due to their stationary design.

Cost Considerations: Rotary vs Flatbed

Rotary screen printing generally offers lower cost per unit in high-volume production due to its continuous printing process and faster output. Flatbed screen printing incurs higher setup costs and slower speeds, making it more suitable for small runs or detailed prints where precision outweighs speed. Your choice between rotary and flatbed methods will depend on balancing initial investment against long-term production efficiency and budget constraints.

Choosing the Right Screen Printing Method

Rotary screen printing offers high-speed production suitable for continuous patterns and large-volume runs, making it ideal for textiles and cylindrical objects. Flatbed screen printing provides precise, high-quality prints with better control over details, perfect for flat surfaces and small to medium batches. Choosing the right screen printing method depends on factors like material type, print complexity, production volume, and cost efficiency.

Rotary screen printing vs Flatbed screen printing Infographic

libmatt.com

libmatt.com