Rapier looms excel in versatility and fabric width, making them ideal for lightweight to medium-weight textiles, while projectile looms offer high-speed weaving suited for heavier fabrics and industrial applications. Your choice depends on fabric type and production speed requirements, as rapier looms provide precision and flexibility, whereas projectile looms deliver robust performance for dense materials.

Table of Comparison

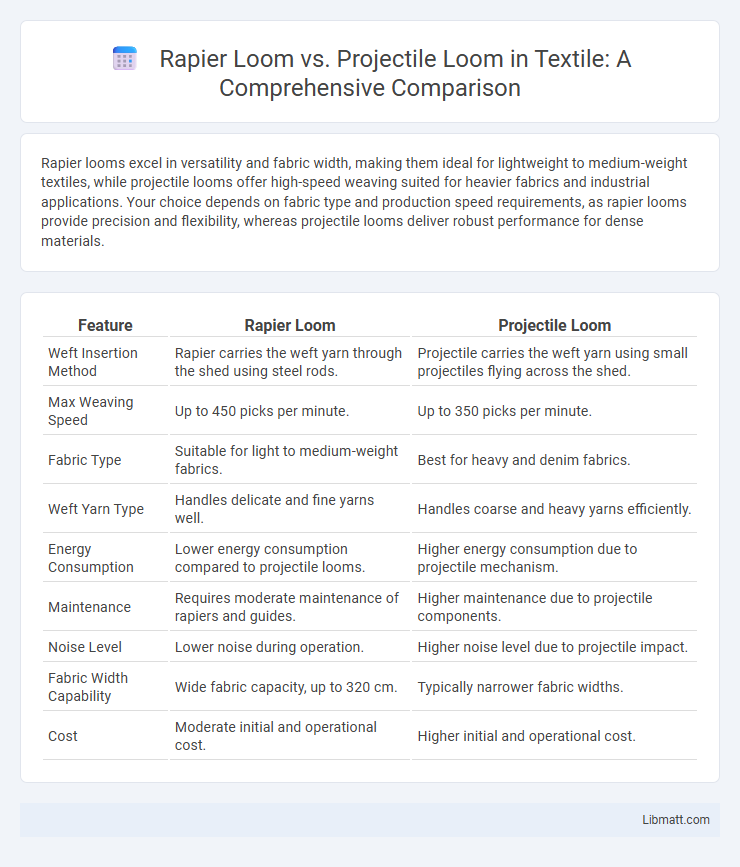

| Feature | Rapier Loom | Projectile Loom |

|---|---|---|

| Weft Insertion Method | Rapier carries the weft yarn through the shed using steel rods. | Projectile carries the weft yarn using small projectiles flying across the shed. |

| Max Weaving Speed | Up to 450 picks per minute. | Up to 350 picks per minute. |

| Fabric Type | Suitable for light to medium-weight fabrics. | Best for heavy and denim fabrics. |

| Weft Yarn Type | Handles delicate and fine yarns well. | Handles coarse and heavy yarns efficiently. |

| Energy Consumption | Lower energy consumption compared to projectile looms. | Higher energy consumption due to projectile mechanism. |

| Maintenance | Requires moderate maintenance of rapiers and guides. | Higher maintenance due to projectile components. |

| Noise Level | Lower noise during operation. | Higher noise level due to projectile impact. |

| Fabric Width Capability | Wide fabric capacity, up to 320 cm. | Typically narrower fabric widths. |

| Cost | Moderate initial and operational cost. | Higher initial and operational cost. |

Overview of Rapier and Projectile Looms

Rapier looms use flexible or rigid rods (rapiers) to carry the weft yarn through the shed, enabling high versatility in fabric types and yarns. Projectile looms employ small projectiles that shoot across the shed to insert the weft, offering superior speed and efficiency for heavier and longer weft yarns. Your choice depends on fabric complexity and production speed, with rapier looms excelling in adaptability and projectile looms providing faster output for specific materials.

Working Principle of Rapier Looms

Rapier looms operate by using a flexible or rigid rapier to carry the weft yarn through the shed, maneuvering the filling yarn across the warp threads with precision and high speed. The rapier system offers excellent fabric quality and versatility, handling delicate or heavy yarns without damage. Your choice of rapier looms can enhance productivity in weaving complex patterns while reducing yarn breakage compared to projectile looms.

Working Principle of Projectile Looms

Projectile looms operate by using small, bullet-shaped projectiles to carry the weft yarn through the warp shed, propelled mechanically across the loom width. This mechanism enables high-speed weaving of heavy and dense fabrics with minimal yarn tension and reduced breakage risk. The precise control of projectile motion enhances fabric uniformity and supports efficient production of wide and complex textile patterns.

Key Technological Differences

Rapier looms utilize flexible steel or carbon fiber tapes to carry the weft yarn through the shed, enabling high-speed weaving with low energy consumption. Projectile looms use small, bullet-like projectiles to shoot the weft yarn across wide, heavy warp fabrics, providing excellent suitability for dense and heavy materials. The primary technological difference lies in the weft insertion method, with rapier looms favoring precision and versatility, while projectile looms excel in handling tougher fabrics at moderate speeds.

Yarn and Fabric Compatibility

Rapier looms offer superior versatility in handling a wide range of yarn types, including fine, delicate fibers and heavier yarns, making them ideal for producing diverse fabric qualities with high precision. Projectile looms are better suited for heavier and coarser yarns, often used in denim and upholstery fabrics, due to their robust mechanism that can manage thicker materials without damage. Your choice depends on the specific fabric requirements and yarn compatibility, with rapier looms providing more finesse and projectile looms excelling in durability and speed for heavy textiles.

Production Speed Comparison

Rapier looms typically achieve production speeds ranging from 250 to 350 picks per minute, making them suitable for medium to heavy fabrics with moderate production demands. Projectile looms can reach speeds up to 350 picks per minute but excel in weaving finer and more delicate fabrics with higher precision. While both looms offer competitive speeds, rapier looms provide greater versatility in yarn types, whereas projectile looms prioritize consistent high-speed performance for lighter materials.

Maintenance and Operational Costs

Rapier looms generally incur lower maintenance and operational costs due to fewer moving parts and less complex shuttle mechanisms compared to projectile looms. Projectile looms experience higher wear and frequent replacement of projectiles and grippers, increasing downtime and maintenance expenses. The energy consumption of rapier looms is also typically reduced, contributing to overall cost efficiency in textile manufacturing.

Energy Efficiency and Power Consumption

Rapier looms exhibit higher energy efficiency compared to projectile looms due to their lighter weft insertion mechanisms that require less power. Projectile looms consume more energy because they rely on heavy metal projectiles propelled at high speeds, increasing power consumption significantly. Your choice of loom impacts operational costs, with rapier looms offering lower power consumption and better energy savings for fabric production.

Advantages and Disadvantages of Each Loom

Rapier looms offer high versatility and can handle a wide range of yarn types and fabric widths, making them ideal for producing delicate and complex textiles with minimal yarn breakage; however, their slower speed compared to projectile looms may limit efficiency in large-scale production. Projectile looms excel in high-speed weaving and robustness, delivering faster output and better performance with heavy or coarse yarns, but they tend to consume more energy and generate greater noise, which could impact your operational environment. Choosing between rapier and projectile looms depends on your specific fabric requirements, production volume, and tolerance for operational conditions.

Choosing the Right Loom for Textile Manufacturing

Selecting the right loom for textile manufacturing hinges on fabric type and production speed requirements. Rapier looms excel in weaving fine and delicate fabrics with high precision, offering versatility across yarn types, while projectile looms are favored for heavyweight and coarse materials due to their robust mechanism and durability. Evaluating factors such as production volume, fabric complexity, and operational cost ensures optimal performance and quality in textile manufacturing.

Rapier loom vs Projectile loom Infographic

libmatt.com

libmatt.com