Wet spinning uses a coagulating solvent to solidify polymer solutions into fibers, making it ideal for producing fibers with high tensile strength and uniformity. Dry spinning evaporates the solvent through heated air, enabling faster fiber formation and suitability for polymers that dissolve in volatile solvents, enhancing your choice based on material and production speed requirements.

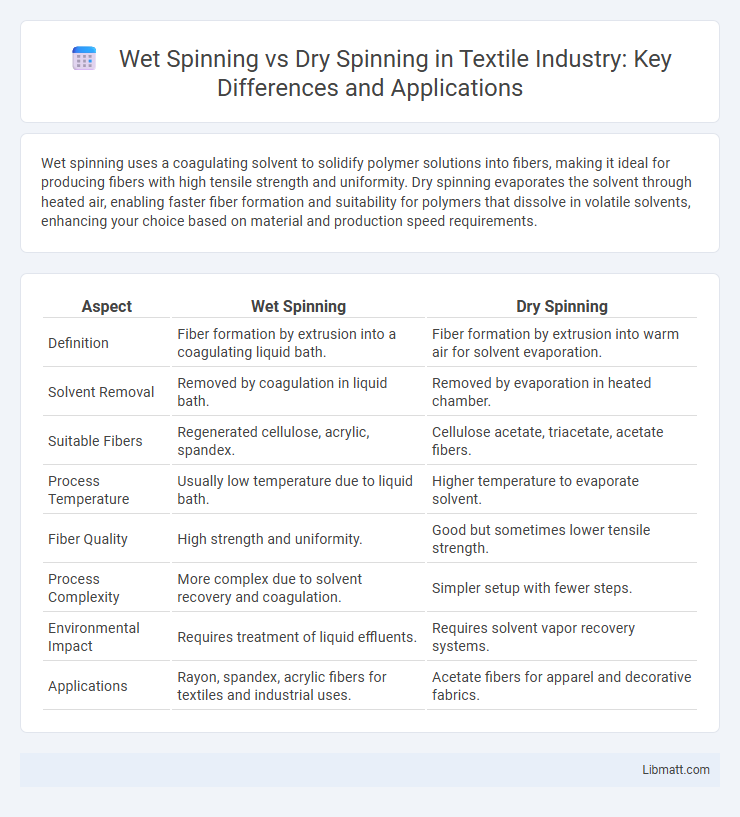

Table of Comparison

| Aspect | Wet Spinning | Dry Spinning |

|---|---|---|

| Definition | Fiber formation by extrusion into a coagulating liquid bath. | Fiber formation by extrusion into warm air for solvent evaporation. |

| Solvent Removal | Removed by coagulation in liquid bath. | Removed by evaporation in heated chamber. |

| Suitable Fibers | Regenerated cellulose, acrylic, spandex. | Cellulose acetate, triacetate, acetate fibers. |

| Process Temperature | Usually low temperature due to liquid bath. | Higher temperature to evaporate solvent. |

| Fiber Quality | High strength and uniformity. | Good but sometimes lower tensile strength. |

| Process Complexity | More complex due to solvent recovery and coagulation. | Simpler setup with fewer steps. |

| Environmental Impact | Requires treatment of liquid effluents. | Requires solvent vapor recovery systems. |

| Applications | Rayon, spandex, acrylic fibers for textiles and industrial uses. | Acetate fibers for apparel and decorative fabrics. |

Introduction to Spinning Techniques

Wet spinning involves extruding a polymer solution into a coagulation bath where fibers solidify, while dry spinning uses solvent evaporation in a heated chamber to form fibers. Both techniques are essential in producing synthetic fibers like rayon, acetate, and spandex, each offering distinct advantages depending on polymer solubility and desired fiber properties. Understanding these differences helps you select the optimal spinning method for specific textile applications.

What is Wet Spinning?

Wet spinning is a fiber production method where a polymer solution is extruded into a coagulation bath, causing the fibers to solidify as the solvent diffuses out. This technique is commonly used for fibers like acrylic, rayon, and spandex, offering better control over fiber properties such as strength and elasticity. You benefit from wet spinning's ability to produce high-quality, uniform fibers suitable for applications requiring durability and flexibility.

What is Dry Spinning?

Dry spinning is a fiber production process where a polymer solution is extruded through spinnerets into a heated chamber, causing the solvent to evaporate and solid fibers to form. This method is ideal for producing materials like acetate, acrylic, and spandex, where solvent recovery and fiber uniformity are critical. Understanding dry spinning helps you choose the right technique for applications requiring high-quality synthetic fibers with controlled porosity and strength.

Key Differences between Wet and Dry Spinning

Wet spinning involves extruding a polymer solution into a coagulation bath where fibers solidify through solvent exchange, while dry spinning extrudes the polymer solution into a heated chamber causing solvent evaporation to form fibers. Wet spinning suits polymers insoluble in common solvents and produces fibers with high tensile strength and uniformity, whereas dry spinning is ideal for polymers soluble in volatile solvents and achieves faster production rates but may result in lower fiber uniformity. The key differences lie in the solvent removal method, fiber properties, and applicable polymer types, impacting industrial applications in textiles and advanced materials manufacturing.

Process Steps in Wet Spinning

Wet spinning involves extruding a polymer solution through a spinneret into a coagulation bath where the fibers solidify by solvent removal and filament regeneration. The process steps include preparing the polymer dope, pumping it through spinnerets, passing the filaments into a liquid coagulation medium, washing to remove residual solvent, and drying the filaments. This method is essential for fibers like rayon and spandex, which require liquid phase solidification for proper fiber formation.

Process Steps in Dry Spinning

Dry spinning involves dissolving a polymer in a volatile solvent, then extruding the solution through spinnerets into a heated chamber where the solvent evaporates, leaving behind solid fibers. Key process steps include solution preparation, extrusion, solvent evaporation in the drying zone, and fiber collection on a winder. This method is widely used for producing fibers like acetate, spandex, and certain acrylics due to its ability to control fiber diameter and properties effectively.

Advantages of Wet Spinning

Wet spinning produces fibers with superior tensile strength and uniformity due to controlled coagulation in a liquid bath, enhancing fiber durability and quality. This method allows spinning of polymers insoluble in common solvents, expanding material versatility for applications like acrylics and spandex. Wet spinning also offers better control over fiber morphology and diameter, resulting in improved mechanical properties and consistent fiber production.

Advantages of Dry Spinning

Dry spinning offers several advantages, including faster production rates due to rapid solvent evaporation, which eliminates the need for coagulation baths used in wet spinning. This method allows better control over fiber structure, resulting in enhanced mechanical properties and improved surface smoothness. Your choice of dry spinning can lead to cost savings by reducing water usage and simplifying waste management processes.

Common Applications of Wet and Dry Spinning

Wet spinning is commonly used for producing fibers such as rayon, acrylic, and spandex, which require coagulation in a chemical bath to solidify. Dry spinning is typically applied to manufacture fibers like acetate, triacetate, and some synthetic fibers where solvent evaporation solidifies the filaments. Your choice between wet and dry spinning depends on the fiber type and desired material properties for applications in textiles, medical sutures, or specialty fabrics.

Choosing the Right Spinning Method

Choosing the right spinning method depends on the fiber type and desired yarn properties, with wet spinning ideal for cellulose and acrylic fibers due to its ability to handle high molecular weight polymers and produce fine, strong filaments. Dry spinning suits thermoplastics like acetate, where solvent evaporation solidifies the fiber quickly, enabling efficient production with smoother surface textures. Your selection should consider processing speed, fiber durability, and end-use applications to optimize performance and cost-effectiveness.

Wet spinning vs Dry spinning Infographic

libmatt.com

libmatt.com