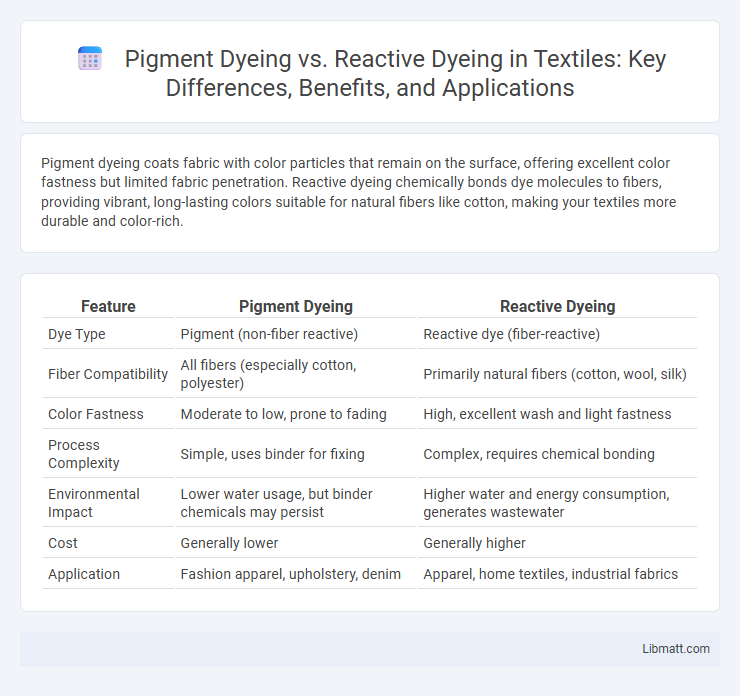

Pigment dyeing coats fabric with color particles that remain on the surface, offering excellent color fastness but limited fabric penetration. Reactive dyeing chemically bonds dye molecules to fibers, providing vibrant, long-lasting colors suitable for natural fibers like cotton, making your textiles more durable and color-rich.

Table of Comparison

| Feature | Pigment Dyeing | Reactive Dyeing |

|---|---|---|

| Dye Type | Pigment (non-fiber reactive) | Reactive dye (fiber-reactive) |

| Fiber Compatibility | All fibers (especially cotton, polyester) | Primarily natural fibers (cotton, wool, silk) |

| Color Fastness | Moderate to low, prone to fading | High, excellent wash and light fastness |

| Process Complexity | Simple, uses binder for fixing | Complex, requires chemical bonding |

| Environmental Impact | Lower water usage, but binder chemicals may persist | Higher water and energy consumption, generates wastewater |

| Cost | Generally lower | Generally higher |

| Application | Fashion apparel, upholstery, denim | Apparel, home textiles, industrial fabrics |

Introduction to Pigment and Reactive Dyeing

Pigment dyeing involves applying color particles that adhere to the fabric surface without chemically bonding, offering vibrant hues and excellent colorfastness on various materials. Reactive dyeing uses reactive dyes that form covalent bonds with cellulose fibers, producing bright, long-lasting colors ideal for cotton and other natural fibers. Your choice between pigment and reactive dyeing depends on fabric type, desired color intensity, and wash durability.

Key Differences Between Pigment and Reactive Dyeing

Pigment dyeing uses color pigments that adhere to fabric surfaces via binders, resulting in less colorfastness but vibrant shades suitable for diverse materials. Reactive dyeing forms covalent bonds between dye and fiber, offering superior wash and light fastness, especially on cellulose fibers like cotton. Your choice depends on desired durability, fabric type, and end-use requirements.

Overview of Pigment Dyeing Process

Pigment dyeing involves applying color pigments to the fabric surface using a binder to fix the pigment, unlike reactive dyeing which forms a chemical bond with the fiber. This process offers vibrant colors and good coverage on different fabric types, including cotton and synthetics, but may have lower wash fastness compared to reactive dyes. Your choice of pigment dyeing is ideal for achieving unique, textured effects and durable color on a variety of materials without extensive chemical treatment.

Overview of Reactive Dyeing Process

Reactive dyeing involves the chemical bonding of dye molecules to cellulose fibers, primarily cotton, through a covalent bond formed during the fixation stage, ensuring high color fastness and vibrant hues. The process typically includes fiber pretreatment to remove impurities, immersion in an alkaline dye bath for dye fixation, followed by rinsing to eliminate unfixed dye and improve color durability. Compared to pigment dyeing, reactive dyeing offers superior wash and light fastness due to its molecular bonding with fabric fibers.

Colorfastness: Pigment vs Reactive Dyes

Pigment dyeing offers lower colorfastness compared to reactive dyeing, as pigments sit on the fabric surface rather than chemically bonding with fibers. Reactive dyes form strong covalent bonds with cellulose fibers, resulting in superior wash, light, and rub fastness. Your choice between pigment and reactive dyes should consider the durability of color required for the specific textile application.

Environmental Impact: Pigment vs Reactive Dyeing

Pigment dyeing has a lower environmental impact than reactive dyeing because it uses less water and fewer chemicals, reducing wastewater pollution. Reactive dyeing involves complex chemical reactions that consume significant amounts of water and energy, often resulting in effluents with harmful substances requiring extensive treatment. Choosing pigment dyeing can help your textile production minimize ecological footprint and conserve natural resources.

Fabric Compatibility and Applications

Pigment dyeing is compatible with a wide range of fabrics, including cotton, polyester, and blends, as it relies on pigments that adhere to the fabric surface rather than penetrating fibers. Reactive dyeing works best with cellulose fibers like cotton, linen, and rayon, providing strong colorfastness through a chemical reaction with the fabric. Pigment dyeing is commonly used for denim and upholstery due to its vibrant, resistant finish, while reactive dyeing is preferred in apparel and home textiles for its bright hues and wash durability.

Cost Analysis: Pigment Dyeing vs Reactive Dyeing

Pigment dyeing generally incurs lower costs due to simpler processing steps and reduced water and energy consumption compared to reactive dyeing, which requires more expensive chemicals and complex fixation processes. Reactive dyeing, while costlier, offers superior colorfastness and vibrancy, potentially reducing long-term expenses related to fading or color loss. Evaluating total production costs involves balancing initial dyeing expenses against product durability and quality demands in textile manufacturing.

Advantages and Disadvantages of Each Method

Pigment dyeing offers advantages such as vibrant colors and excellent colorfastness on a wide range of fabrics, with the added benefit of being environmentally friendly due to minimal water usage, but it often results in less softness and poor penetration compared to reactive dyeing. Reactive dyeing provides superior color brightness, better dye fixation, and strong fiber-reactive bonds, making it ideal for cotton and cellulose fibers; however, it requires more water, energy, and generates higher chemical waste, impacting environmental sustainability. Choosing between pigment and reactive dyeing depends on fabric type, desired color performance, and environmental considerations, balancing durability against ecological impact.

Choosing the Right Dyeing Technique for Your Needs

Pigment dyeing offers excellent color fastness and surface coloration, making it ideal for fabrics requiring vibrant, short-run designs with minimal water usage. Reactive dyeing chemically bonds dye to fibers, providing superior wash and light fastness, best suited for high-quality cotton fabrics demanding long-lasting, even coloration. Selecting between pigment and reactive dyeing depends on fabric type, desired durability, and environmental considerations, with reactive dyeing favored for cellulosic fibers and pigment dyeing preferred for quick, eco-friendly applications.

Pigment dyeing vs Reactive dyeing Infographic

libmatt.com

libmatt.com