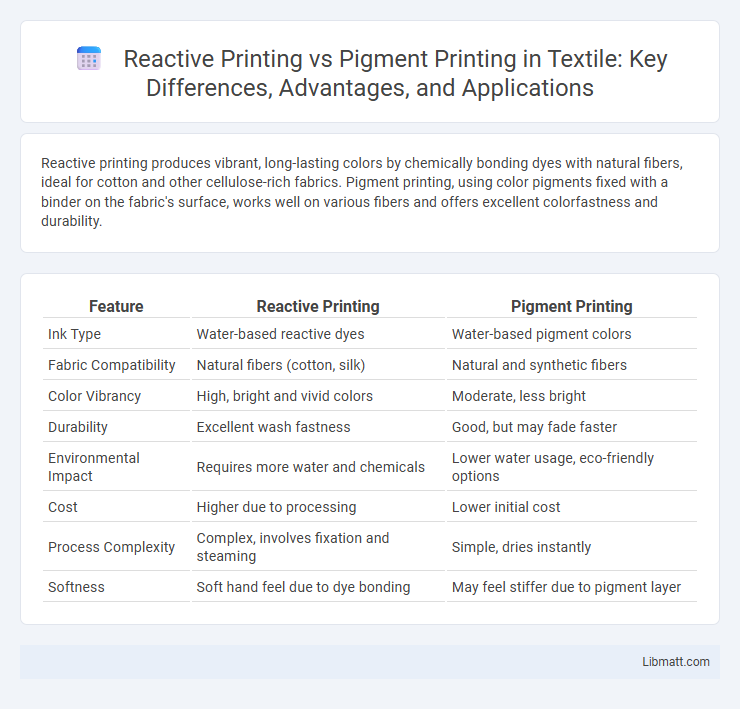

Reactive printing produces vibrant, long-lasting colors by chemically bonding dyes with natural fibers, ideal for cotton and other cellulose-rich fabrics. Pigment printing, using color pigments fixed with a binder on the fabric's surface, works well on various fibers and offers excellent colorfastness and durability.

Table of Comparison

| Feature | Reactive Printing | Pigment Printing |

|---|---|---|

| Ink Type | Water-based reactive dyes | Water-based pigment colors |

| Fabric Compatibility | Natural fibers (cotton, silk) | Natural and synthetic fibers |

| Color Vibrancy | High, bright and vivid colors | Moderate, less bright |

| Durability | Excellent wash fastness | Good, but may fade faster |

| Environmental Impact | Requires more water and chemicals | Lower water usage, eco-friendly options |

| Cost | Higher due to processing | Lower initial cost |

| Process Complexity | Complex, involves fixation and steaming | Simple, dries instantly |

| Softness | Soft hand feel due to dye bonding | May feel stiffer due to pigment layer |

Introduction to Textile Printing Methods

Reactive printing uses water-based dyes that chemically bond with the fabric fibers, producing vibrant and long-lasting colors ideal for natural textiles like cotton. Pigment printing relies on color pigments that adhere to the fabric surface with a binder, offering versatility across various materials but often resulting in less colorfastness. Your choice between these textile printing methods depends on the fabric type, desired color durability, and environmental considerations.

What is Reactive Printing?

Reactive printing is a textile dyeing process where reactive dyes chemically bond with cellulose fibers, resulting in vibrant, durable, and wash-fast colors on natural fabrics such as cotton. This method relies on a chemical reaction between the dye and fiber, forming a covalent bond that enhances colorfastness and brightness. Reactive printing is preferred for its eco-friendly properties and excellent print quality on natural textiles compared to pigment printing, which simply deposits color on the fabric surface without permanent bonding.

What is Pigment Printing?

Pigment printing is a textile printing technique where pigments are applied to the fabric surface and fixed using binders, creating a durable and vibrant design without penetrating the fibers. Unlike reactive printing, which bonds chemically with the fabric, pigment printing relies on adhesion, making it suitable for a wide range of materials including polyester and cotton blends. This method offers excellent color fastness and is often preferred for producing vivid patterns on dark or synthetic fabrics.

Chemical Processes in Reactive vs Pigment Printing

Reactive printing involves chemical reactions where dye molecules form covalent bonds with cellulose fibers, ensuring vibrant, durable colors that are wash-fast and resistant to fading. Pigment printing relies on coating fabric with color particles bound by a resin without bonding chemically to fibers, resulting in a less permeable print prone to cracking or peeling over time. Understanding these chemical processes helps you choose between the long-lasting vibrancy of reactive dyes and the versatility of pigment prints for your textile needs.

Color Vibrancy and Fastness Compared

Reactive printing offers superior color vibrancy and longer-lasting fastness because the dyes chemically bond with the fabric fibers, resulting in bright, vivid hues that resist fading through washing and sunlight exposure. Pigment printing, while providing good coverage and surface-level color, tends to have less intense vibrancy and lower fastness, as the pigments sit on top of the fabric and can wear off over time. Your choice between the two printing methods should consider the desired color longevity and brightness for the textile application.

Fabric Compatibility: Reactive vs Pigment Inks

Reactive printing inks are highly compatible with natural fibers such as cotton, linen, and silk due to their ability to form a chemical bond with cellulose fibers, resulting in vibrant colors and excellent wash fastness. Pigment printing inks offer broader fabric compatibility, being suitable for both natural and synthetic materials like polyester and nylon, but they sit on the fabric surface without forming a chemical bond, which may affect durability. The choice between reactive and pigment inks depends on the fabric type and desired longevity, with reactive inks preferred for natural fibers and pigment inks for diverse or synthetic textiles.

Environmental Impact and Sustainability

Reactive printing uses dye that chemically bonds with the fabric, resulting in vibrant colors and better wash durability while generating less water pollution compared to pigment printing. Pigment printing applies color on the fabric surface, often requiring more water and chemicals for fixation and washing, leading to higher environmental impact. Choosing reactive printing supports your sustainability goals by reducing harmful waste and conserving water resources in textile production.

Cost Considerations in Production

Reactive printing typically involves higher production costs due to the need for precise temperature control and longer fixation times, which increases energy consumption and labor expenses. Pigment printing is generally more cost-effective because it requires no steaming or washing steps, reducing water and chemical usage and enabling faster turnaround times. Your decision should weigh initial investment against long-term operational expenses and fabric compatibility to optimize production budgeting.

End-Use Applications and Performance

Reactive printing excels in textile applications requiring vibrant colors and soft fabric feel, making it ideal for fashion and home textiles. Pigment printing offers superior durability and color fastness on a variety of fabrics, suited for upholstery, outdoor gear, and industrial uses. Both methods differ in wash resistance and environmental impact, influencing their choice based on performance needs and end-use demands.

Choosing the Right Printing Method

Choosing the right printing method depends on the fabric type and desired durability; reactive printing is ideal for natural fibers like cotton, offering vibrant colors and excellent wash fastness due to its dye's chemical bonding. Pigment printing suits a wider range of fabrics, including synthetics, providing surface-level color saturation that allows quick drying but with lower wash resistance. Cost considerations and end-use, such as garment longevity and environmental impact, also play critical roles in selecting either reactive or pigment printing for textile production.

Reactive printing vs Pigment printing Infographic

libmatt.com

libmatt.com