Mercerized finishing enhances fabric strength, luster, and dye affinity by treating cotton fibers with a caustic soda solution under tension, resulting in a smoother, more lustrous surface. Caustic finishing also uses caustic soda but focuses on swelling and shrinking fibers to improve fabric texture and durability, often making your textiles more resilient and comfortable.

Table of Comparison

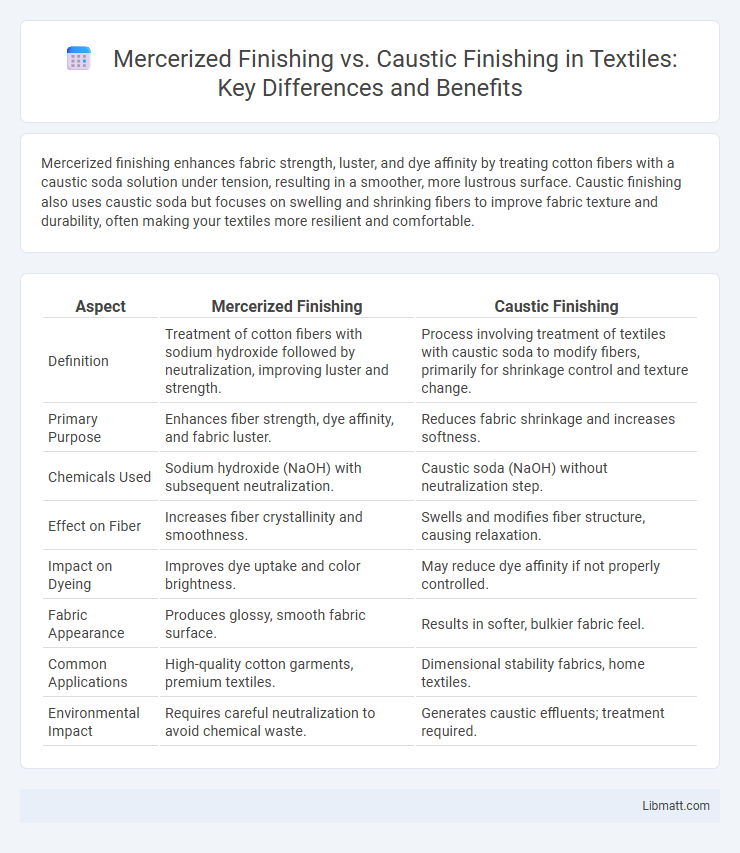

| Aspect | Mercerized Finishing | Caustic Finishing |

|---|---|---|

| Definition | Treatment of cotton fibers with sodium hydroxide followed by neutralization, improving luster and strength. | Process involving treatment of textiles with caustic soda to modify fibers, primarily for shrinkage control and texture change. |

| Primary Purpose | Enhances fiber strength, dye affinity, and fabric luster. | Reduces fabric shrinkage and increases softness. |

| Chemicals Used | Sodium hydroxide (NaOH) with subsequent neutralization. | Caustic soda (NaOH) without neutralization step. |

| Effect on Fiber | Increases fiber crystallinity and smoothness. | Swells and modifies fiber structure, causing relaxation. |

| Impact on Dyeing | Improves dye uptake and color brightness. | May reduce dye affinity if not properly controlled. |

| Fabric Appearance | Produces glossy, smooth fabric surface. | Results in softer, bulkier fabric feel. |

| Common Applications | High-quality cotton garments, premium textiles. | Dimensional stability fabrics, home textiles. |

| Environmental Impact | Requires careful neutralization to avoid chemical waste. | Generates caustic effluents; treatment required. |

Introduction to Mercerized and Caustic Finishing

Mercerized finishing involves treating cotton fabrics with a caustic soda solution under tension to enhance luster, strength, and dye affinity. Caustic finishing, commonly used on fibers like viscose and cotton blends, applies controlled alkali treatment to improve fabric texture and absorbency. Understanding these treatments helps you select the right finishing process for optimal fabric performance and appearance.

Definition and Process of Mercerized Finishing

Mercerized finishing is a textile treatment process that involves soaking cotton fibers or fabrics in a strong sodium hydroxide (caustic soda) solution, followed by washing and neutralizing, to enhance their luster, strength, and dye affinity. This chemical treatment causes the fibers to swell, resulting in a smoother surface and increased tensile strength, which improves fabric quality and appearance. Compared to caustic finishing, which generally focuses on fabric dimensional stability and cleanliness, mercerization specifically targets fiber structure transformation to elevate aesthetic and functional properties.

Definition and Process of Caustic Finishing

Caustic finishing involves treating cotton fabrics with a concentrated sodium hydroxide solution, causing the fibers to swell and partially dissolve, which results in a smoother, more lustrous surface. This chemical process alters the fiber structure by transforming cellulose into alkali cellulose, enhancing fabric strength, dye affinity, and resistance to shrinkage. Unlike mercerized finishing, which uses milder alkali and tension to improve luster and dye uptake, caustic finishing aggressively modifies the fabric at a molecular level for distinct performance benefits.

Key Chemical Agents Involved

Mercerized finishing involves treating cotton fibers with a strong caustic soda (sodium hydroxide) solution followed by neutralization, enhancing luster, strength, and dye affinity. Caustic finishing primarily uses sodium hydroxide to swell and modify fiber structure without subsequent neutralization, focusing more on dimensional stability and texture changes. Understanding these key chemical agents helps optimize your fabric's durability and aesthetic properties based on the finishing technique used.

Textile Fiber Types Affected

Mercerized finishing primarily enhances cellulosic fibers such as cotton and flax by increasing luster, strength, and dye affinity through swelling of the fiber. Caustic finishing targets synthetic fibers like polyester and polypropylene, improving surface texture and dye uptake by altering the fiber's molecular structure. Both processes modify the physical and chemical properties of fibers but are selectively applied based on the fiber type to achieve optimal textile performance.

Impact on Fabric Strength and Appearance

Mercerized finishing enhances fabric strength by causing fibers to swell, increasing tensile strength and giving cotton a smoother, more lustrous appearance with improved dye uptake. In contrast, caustic finishing uses sodium hydroxide to modify fiber properties, which can slightly weaken fabric strength but significantly increases fabric absorbency and improves texture by making fibers more flexible. Mercerized fabric generally exhibits superior durability and sheen, while caustic finishing prioritizes softness and water absorbency at some cost to tensile integrity.

Dye Affinity and Color Vibrancy Differences

Mercerized finishing significantly enhances dye affinity by increasing fiber's surface area and reactivity, resulting in deeper, more uniform color penetration and vibrant hues. Caustic finishing modifies fiber morphology by swelling the fibers, improving dye uptake but often yielding less color intensity compared to mercerization. The superior luster and colorfastness of mercerized cotton distinguish it from caustic-treated fibers, making it preferable for high-quality textile applications demanding vivid and long-lasting colors.

Environmental and Safety Considerations

Mercerized finishing involves the use of strong caustic soda, which requires careful handling and disposal to minimize environmental impact and ensure worker safety due to its corrosive nature. Caustic finishing also involves sodium hydroxide but often in higher concentrations, increasing risks of chemical burns and environmental hazards if waste is not properly treated. You should prioritize facilities that implement stringent waste management and use protective measures to reduce potential harm during both finishing processes.

Cost and Industrial Applications

Mercerized finishing involves treating cotton fibers with a strong alkali to enhance luster, strength, and dye uptake, typically resulting in higher production costs due to additional processing steps and chemical usage. Caustic finishing, commonly used for fabrics like polyester-cotton blends, is generally more cost-effective as it simplifies fiber treatment by swelling and softening fibers without extensive processing. Your choice between these finishes should consider budget constraints and the specific industrial application, with mercerization favored for premium textiles and caustic finishing suited for mass-produced, durable fabrics.

Choosing Between Mercerized and Caustic Finishing

Choosing between mercerized and caustic finishing depends on the desired fabric characteristics and end-use applications. Mercerized finishing enhances cotton strength, improves luster, and increases dye affinity by treating the fabric with caustic soda under tension, ideal for high-quality garments. Caustic finishing, on the other hand, primarily alters fabric texture by swelling fibers and increasing absorbency, commonly used in denim production to achieve softness and improved dye penetration.

Mercerized finishing vs Caustic finishing Infographic

libmatt.com

libmatt.com