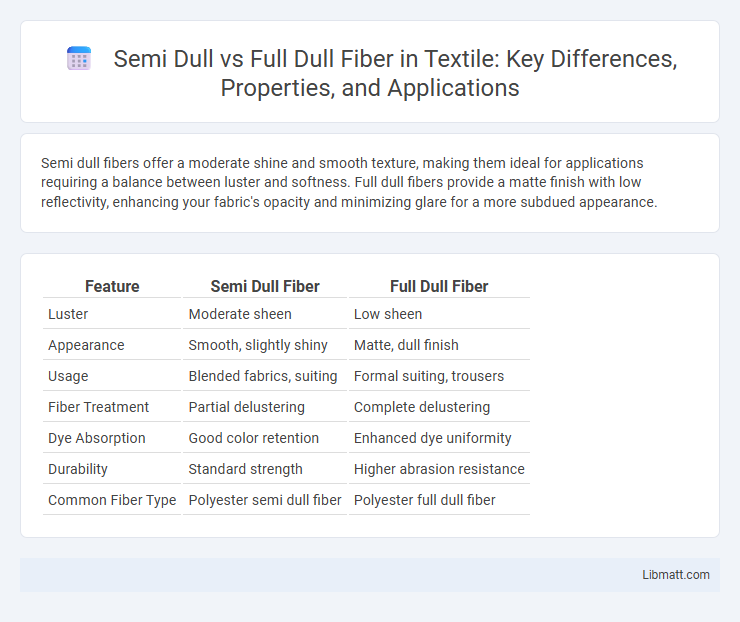

Semi dull fibers offer a moderate shine and smooth texture, making them ideal for applications requiring a balance between luster and softness. Full dull fibers provide a matte finish with low reflectivity, enhancing your fabric's opacity and minimizing glare for a more subdued appearance.

Table of Comparison

| Feature | Semi Dull Fiber | Full Dull Fiber |

|---|---|---|

| Luster | Moderate sheen | Low sheen |

| Appearance | Smooth, slightly shiny | Matte, dull finish |

| Usage | Blended fabrics, suiting | Formal suiting, trousers |

| Fiber Treatment | Partial delustering | Complete delustering |

| Dye Absorption | Good color retention | Enhanced dye uniformity |

| Durability | Standard strength | Higher abrasion resistance |

| Common Fiber Type | Polyester semi dull fiber | Polyester full dull fiber |

Introduction to Semi Dull and Full Dull Fibers

Semi dull fibers exhibit a moderate level of sheen, offering a balance between gloss and matte appearance ideal for textiles requiring subtle luster. Full dull fibers have minimal reflectance, providing a matte finish favored in applications demanding low shine and a natural look. Both fiber types differ primarily in their surface treatment and polymer morphology, which influence their optical properties and end-use suitability.

Definition of Semi Dull Fiber

Semi dull fiber refers to a type of synthetic yarn with a moderate luster level, positioned between bright and dull finishes, commonly used in textile manufacturing for blended, semi-lustrous fabrics. It offers a balanced sheen that enhances fabric appearance while minimizing glare and providing better dye absorption compared to full bright yarns. Semi dull fibers are preferred in garments requiring a subtle shine and good texture, differing from full dull fibers that have a matte finish with minimal luster and a softer hand feel.

Definition of Full Dull Fiber

Full dull fiber refers to synthetic fibers that have a low luster or shine, making them appear matte or non-reflective. These fibers are created by incorporating opacifying agents during the manufacturing process, which scatter light and reduce glossiness. Commonly used in textiles requiring a muted, natural appearance, full dull fibers provide enhanced dye uptake and better fabric opacity compared to their semi dull counterparts.

Key Differences Between Semi Dull and Full Dull Fibers

Semi dull fibers possess a moderate luster, offering a balance between shine and matte appearance, while full dull fibers exhibit minimal reflectivity, resulting in a completely matte finish. The key differences include their surface texture, with semi dull fibers having a partially smooth surface and full dull fibers featuring a rougher texture that enhances dye absorption. Choosing between semi dull and full dull fibers influences the visual effect and tactile feel of your fabric, impacting final product aesthetics and performance.

Manufacturing Process Comparison

Semi dull fiber undergoes a manufacturing process where the polymer filament is partially drawn and heat-set, resulting in a fiber with a subtle matte finish and moderate strength. Full dull fiber is produced through a more intensive drawing and heat-setting process, incorporating additional steps like gelation and extensive stretching to achieve a fully opaque, coarse surface and enhanced durability. Your choice between semi dull and full dull fibers depends on desired fabric texture and end-use performance characteristics influenced by these distinct manufacturing methods.

Physical Properties: Luster, Texture, and Strength

Semi dull fibers exhibit a moderate luster that balances between the high shine of bright fibers and the matte finish of full dull fibers, providing a smooth texture with less reflectivity. Full dull fibers have a matte appearance with minimal shine, resulting in a softer, more natural feel and slightly reduced surface smoothness. In terms of strength, semi dull fibers generally offer better tensile strength and durability compared to full dull fibers, making them suitable for applications requiring a combination of aesthetic appeal and resilience.

Common Applications of Semi Dull Fiber

Semi dull fiber is widely used in applications such as carpets, upholstery, and automotive interiors due to its moderate luster and improved dye affinity compared to full dull fiber. It provides a balance of aesthetics and durability, making it suitable for textiles that require a soft sheen without excessive shine. When you need fibers that enhance color depth and maintain a subdued appearance, semi dull fiber offers an ideal solution.

Common Applications of Full Dull Fiber

Full dull fiber is commonly used in the production of textiles requiring a matte finish, such as formal wear, work uniforms, and upholstery fabrics where reduced shine is essential. It offers enhanced dye uptake and uniform coloration, making it ideal for premium-quality suiting and drapery. The fiber's natural luster reduction also benefits athletic apparel and technical textiles by improving appearance and comfort.

Advantages and Disadvantages of Each Fiber Type

Semi dull fiber offers a subtle sheen and smoother surface ideal for blending and creating lustrous fabrics, with advantages including better dye uptake and reduced static; however, it tends to be less durable and may show wear faster than full dull fiber. Full dull fiber provides a matte finish favored for its superior durability, enhanced resistance to pilling, and excellent moisture-wicking properties, but it has disadvantages such as lower dye affinity and a rougher feel, which can affect comfort. Choosing between semi dull and full dull fibers depends on the desired fabric appearance, performance requirements, and end-use applications.

Choosing the Right Fiber for Your Application

Choosing between semi dull and full dull fiber depends on the specific requirements of your textile application, including desired fabric texture and sheen. Semi dull fiber offers a subtle luster ideal for garments needing a slightly glossy finish, while full dull fiber provides a matte appearance suited for more casual, non-reflective fabrics. Your choice impacts dye uptake, fabric durability, and aesthetic appeal, ensuring optimal performance in the final product.

Semi dull vs Full dull fiber Infographic

libmatt.com

libmatt.com