Fabric luster refers to the overall sheen and shine of the finished textile, influenced by the weaving technique, fiber type, and fabric finish, while yarn luster specifically describes the natural glossiness of the individual yarn fibers before weaving or knitting. Understanding the difference between yarn luster and fabric luster helps you choose materials that enhance the visual appeal and texture of your final garment or textile product.

Table of Comparison

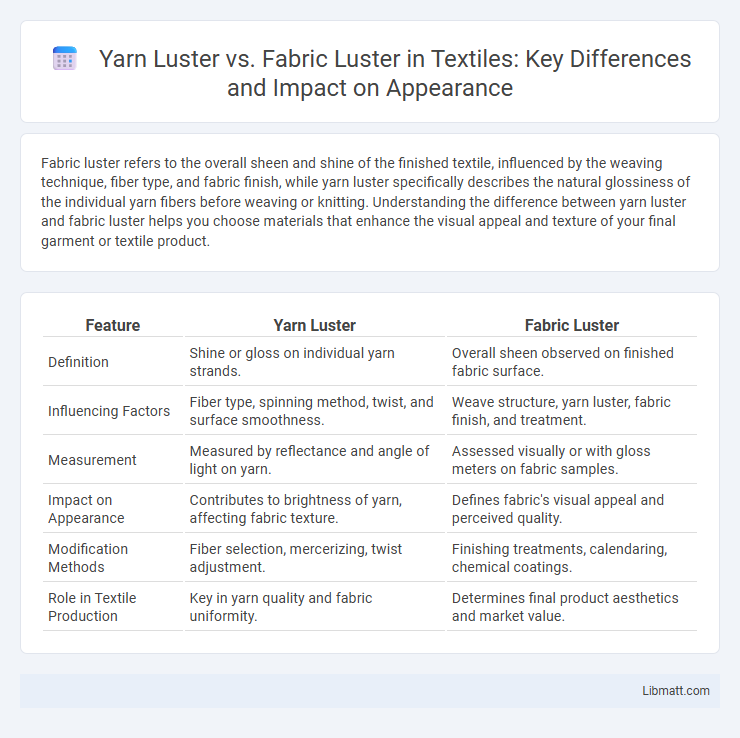

| Feature | Yarn Luster | Fabric Luster |

|---|---|---|

| Definition | Shine or gloss on individual yarn strands. | Overall sheen observed on finished fabric surface. |

| Influencing Factors | Fiber type, spinning method, twist, and surface smoothness. | Weave structure, yarn luster, fabric finish, and treatment. |

| Measurement | Measured by reflectance and angle of light on yarn. | Assessed visually or with gloss meters on fabric samples. |

| Impact on Appearance | Contributes to brightness of yarn, affecting fabric texture. | Defines fabric's visual appeal and perceived quality. |

| Modification Methods | Fiber selection, mercerizing, twist adjustment. | Finishing treatments, calendaring, chemical coatings. |

| Role in Textile Production | Key in yarn quality and fabric uniformity. | Determines final product aesthetics and market value. |

Introduction to Yarn Luster and Fabric Luster

Yarn luster refers to the shine and gloss exhibited by individual fibers or yarns before weaving, influenced by fiber type, spinning techniques, and surface smoothness. Fabric luster emerges from how these yarns are woven or knitted, combined with finishing processes that enhance reflectivity and texture uniformity. Understanding the difference between yarn luster and fabric luster helps you select materials for specific visual and tactile effects in textile products.

Defining Yarn Luster: Characteristics and Importance

Yarn luster refers to the natural shine or gloss exhibited by individual yarn fibers, influenced by factors such as fiber type, smoothness, and twist tightness. This characteristic affects the yarn's ability to reflect light, contributing significantly to the aesthetic appeal and perceived quality of textile products. Understanding yarn luster is crucial for manufacturers and designers aiming to achieve specific fabric appearances and enhance the final product's visual impact.

Understanding Fabric Luster: Key Features

Fabric luster refers to the shine or gloss seen on the surface of a finished textile, influenced by the fiber type, yarn twist, and weaving technique. Unlike yarn luster, which is the inherent shine of individual yarns, fabric luster depends on how light reflects off the fabric's structure and finish. Your choice of fabric luster impacts the garment's aesthetic appeal and perceived quality, making it crucial for design decisions.

Factors Influencing Yarn Luster

Yarn luster is primarily influenced by fiber type, filament length, and the smoothness of the yarn surface, which determine how light reflects off individual fibers. The spinning method and tension also affect yarn luster by altering fiber alignment and compactness, impacting overall brightness and sheen. Understanding these factors allows you to select or produce yarns with desired luster for specific fabric aesthetics.

Factors Affecting Fabric Luster

Factors affecting fabric luster include fiber type, yarn twist, and fabric construction. Natural fibers like silk and polyester offer higher inherent luster due to their smooth surface and light-reflecting properties. Yarn twist influences how light reflects off the fabric, with low twist yarns enhancing luster, while fabric weave or knit structure determines surface texture and overall sheen.

Differences Between Yarn Luster and Fabric Luster

Yarn luster refers to the sheen or shine observed on individual yarns before they are woven or knitted, influenced by fiber type, twist, and surface smoothness. Fabric luster is the overall reflective quality of the finished textile, affected by fabric construction, finishing processes, and surface texture. Differences between yarn luster and fabric luster arise because fabric luster depends not only on the yarn's inherent shine but also on how yarns interact with light once combined and treated in the fabric form.

How Manufacturing Processes Impact Luster

Yarn luster is primarily influenced by the fiber type, spinning technique, and filament length used in manufacturing, which determines the yarn's surface smoothness and light reflectance. Fabric luster results from weaving or knitting methods, finishing treatments, and fabric structure, affecting how light interacts with the fabric as a whole. Understanding these manufacturing processes helps you select the right material with desired sheen for your textile projects.

Effects of Luster on Textile Appearance

Yarn luster significantly influences the texture's visual depth by enhancing the reflection properties of individual fibers, creating a more glossy and vibrant fabric appearance. Fabric luster, determined by the yarn's luster combined with the weaving or knitting technique, affects the overall sheen and smoothness, contributing to a luxurious and polished textile surface. Differences in yarn and fabric luster impact the perceived quality and aesthetic appeal, with high luster fabrics often used in formal wear and high-end upholstery for their elegant shine.

Applications and Significance in the Textile Industry

Yarn luster significantly impacts the aesthetics and hand-feel of finished textiles, making it crucial in applications like fashion apparel and high-end upholstery where visual appeal and tactile quality drive consumer preference. Fabric luster, shaped by both yarn properties and weave or knit structure, influences the durability and light reflectance of textiles, thus playing a key role in home furnishings, sportswear, and technical fabrics that demand functionality alongside appearance. The textile industry's emphasis on balancing yarn luster with fabric construction enhances product differentiation, consumer satisfaction, and market competitiveness.

Choosing the Right Luster for End-Use Products

Yarn luster refers to the shine or sheen of the individual fibers, influencing fabric luster, which is the overall glossiness of the finished textile surface. High yarn luster enhances fabric aesthetics for luxury apparel and evening wear, while moderate fabric luster suits casual clothing, providing subtle elegance and practicality. Selecting the right luster depends on end-use requirements like visual appeal, garment style, and maintenance needs, ensuring optimal product performance and consumer satisfaction.

Yarn Luster vs Fabric Luster Infographic

libmatt.com

libmatt.com