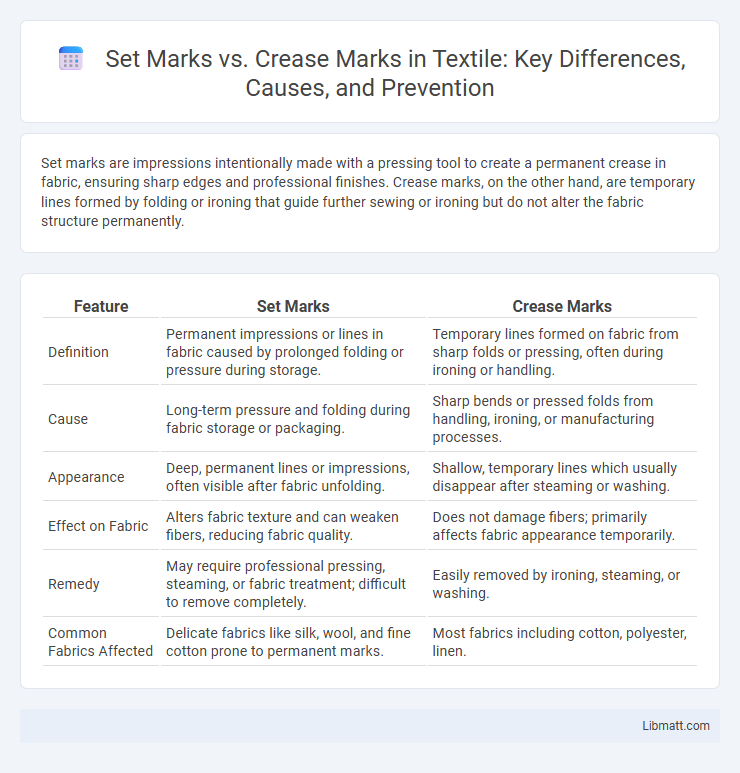

Set marks are impressions intentionally made with a pressing tool to create a permanent crease in fabric, ensuring sharp edges and professional finishes. Crease marks, on the other hand, are temporary lines formed by folding or ironing that guide further sewing or ironing but do not alter the fabric structure permanently.

Table of Comparison

| Feature | Set Marks | Crease Marks |

|---|---|---|

| Definition | Permanent impressions or lines in fabric caused by prolonged folding or pressure during storage. | Temporary lines formed on fabric from sharp folds or pressing, often during ironing or handling. |

| Cause | Long-term pressure and folding during fabric storage or packaging. | Sharp bends or pressed folds from handling, ironing, or manufacturing processes. |

| Appearance | Deep, permanent lines or impressions, often visible after fabric unfolding. | Shallow, temporary lines which usually disappear after steaming or washing. |

| Effect on Fabric | Alters fabric texture and can weaken fibers, reducing fabric quality. | Does not damage fibers; primarily affects fabric appearance temporarily. |

| Remedy | May require professional pressing, steaming, or fabric treatment; difficult to remove completely. | Easily removed by ironing, steaming, or washing. |

| Common Fabrics Affected | Delicate fabrics like silk, wool, and fine cotton prone to permanent marks. | Most fabrics including cotton, polyester, linen. |

Introduction to Set Marks and Crease Marks

Set marks and crease marks are essential indicators used in metal fabrication and woodworking to ensure precise alignment and bending. Set marks refer to the intentional indentations or impressions made to guide where a material should be folded or manipulated, while crease marks are the lines or grooves created during the bending process to reinforce the fold. Understanding the differences between these marks helps improve the accuracy and quality of your finished project.

Defining Set Marks: Meaning and Origin

Set marks refer to subtle impressions or indentations left on fabric after pressing or ironing, often resulting from the pressure and heat used to shape the material. Originating in tailoring and garment manufacturing, set marks serve as guides for folds, seams, or creases to maintain the desired form and structure of clothing. Understanding set marks helps you preserve garment quality by preventing unwanted permanent creases during care or storage.

Understanding Crease Marks in Material Handling

Crease marks are visible indentations or lines caused by improper folding or pressure on materials during handling, affecting their surface integrity and aesthetic quality. Unlike set marks, which are permanent impressions from pressure or tooling, crease marks often indicate weaker structural points and potential damage. Understanding crease marks helps you identify material stress, ensuring better handling practices to maintain product quality and durability.

Key Differences Between Set Marks and Crease Marks

Set marks are permanent indentations made on the fabric during the finishing process to create sharp folds or pleats, while crease marks are temporary lines formed by pressing, intended to be removed after use. Set marks result from prolonged heat and pressure to establish a lasting crease, whereas crease marks arise from short-term ironing and may fade after washing or wear. The key difference lies in durability: set marks provide a permanent shape, whereas crease marks offer reversible shaping.

Causes of Set Marks in Manufacturing Processes

Set marks in manufacturing processes commonly arise from uneven cooling rates, improper die temperature control, or excessive pressure during forming, which cause localized material deformation and surface irregularities. These defects often result from inconsistent equipment settings, material properties, or processing parameters that disrupt smooth material flow. Understanding the causes of set marks allows you to optimize production conditions, enhancing product quality and reducing scrap rates.

Common Factors Leading to Crease Marks

Crease marks commonly result from improper paper handling, such as folding, bending, or stacking under heavy weight, which compresses fibers and leaves permanent indentations. Environmental factors like high humidity and temperature fluctuations can weaken paper integrity, making it more susceptible to creasing. Additionally, mechanical errors during printing or packaging processes, including misaligned rollers or excessive pressure, frequently contribute to the formation of crease marks.

Impacts of Set Marks vs Crease Marks on Product Quality

Set marks, typically caused by improper folding or pressure during manufacturing, lead to visible depressions that can weaken material integrity and reduce aesthetic appeal. Crease marks, resulting from intentional folding or scoring, create controlled lines that enhance product flexibility without compromising structural strength. Differentiating between set marks and crease marks is critical for maintaining high product quality standards, as set marks often indicate defects while crease marks are part of the design process.

Best Practices for Preventing Set and Crease Marks

To prevent set marks, use low-pressure steam and ensure garments are evenly tensioned on the ironing board or press. Avoid excessive heat exposure and properly support fabric fibers by adjusting iron settings according to material type. For crease marks, employ protective pressing cloths and utilize rolling or padding techniques on seams and edges to maintain fabric integrity while applying controlled pressure.

Industry Applications Affected by Set and Crease Marks

Set marks and crease marks significantly impact industries such as packaging, printing, and textiles, where surface quality and precision are critical for product appearance and functionality. In packaging, these marks can lead to product defects, affecting brand perception and customer satisfaction, while in printing, they influence the clarity and finish of printed materials. Textile manufacturing is also affected, as set and crease marks can compromise fabric smoothness, reducing the aesthetic and structural integrity of garments and upholstery.

Conclusion: Managing and Minimizing Set and Crease Marks

Effective management and minimization of set marks and crease marks rely on proper fabric handling, including optimizing ironing temperature and pressure to prevent permanent fabric deformation. Utilizing quality pressing equipment and employing pressing cloths can reduce the risk of unwanted marks, preserving garment integrity and fabric texture. Consistent maintenance of machinery and adherence to fabric-specific care instructions ensure reduced occurrence of both set and crease marks during production and finishing processes.

Set Marks vs Crease Marks Infographic

libmatt.com

libmatt.com