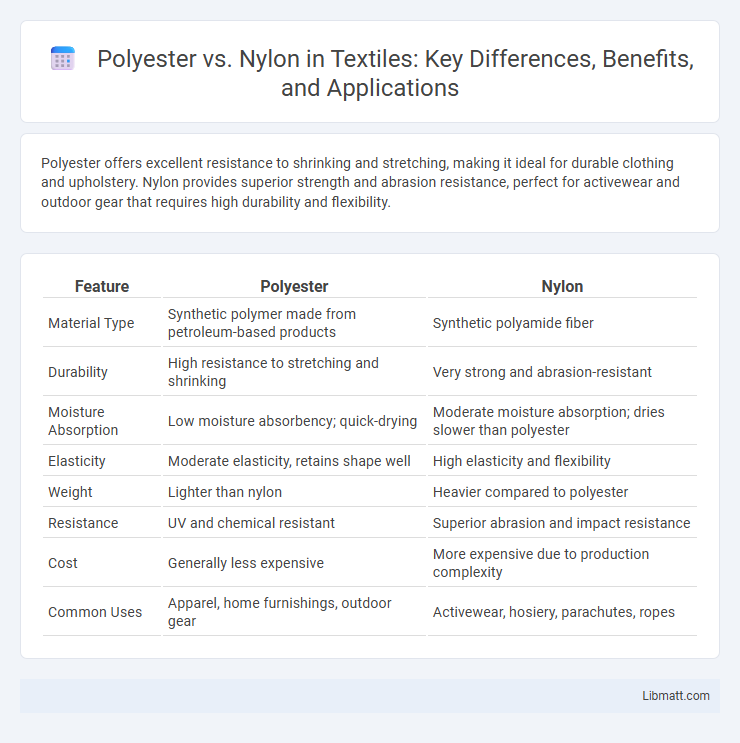

Polyester offers excellent resistance to shrinking and stretching, making it ideal for durable clothing and upholstery. Nylon provides superior strength and abrasion resistance, perfect for activewear and outdoor gear that requires high durability and flexibility.

Table of Comparison

| Feature | Polyester | Nylon |

|---|---|---|

| Material Type | Synthetic polymer made from petroleum-based products | Synthetic polyamide fiber |

| Durability | High resistance to stretching and shrinking | Very strong and abrasion-resistant |

| Moisture Absorption | Low moisture absorbency; quick-drying | Moderate moisture absorption; dries slower than polyester |

| Elasticity | Moderate elasticity, retains shape well | High elasticity and flexibility |

| Weight | Lighter than nylon | Heavier compared to polyester |

| Resistance | UV and chemical resistant | Superior abrasion and impact resistance |

| Cost | Generally less expensive | More expensive due to production complexity |

| Common Uses | Apparel, home furnishings, outdoor gear | Activewear, hosiery, parachutes, ropes |

Introduction to Polyester and Nylon

Polyester and nylon are synthetic fibers widely used in textiles and industrial applications due to their durability and resistance to stretching and shrinking. Polyester, derived from petroleum-based polymers, offers excellent moisture-wicking properties and UV resistance, making it ideal for outdoor apparel. Nylon, known for its superior elasticity and abrasion resistance, is commonly utilized in activewear, hosiery, and technical fabrics requiring high strength and resilience.

Chemical Composition and Structure

Polyester is a synthetic polymer primarily composed of terephthalic acid and ethylene glycol, forming a polyethylene terephthalate (PET) structure characterized by ester functional groups that contribute to its durability and resistance to UV degradation. Nylon, a polyamide, is synthesized from hexamethylene diamine and adipic acid, featuring amide linkages that provide strong hydrogen bonding, resulting in high tensile strength and elasticity. The chemical composition differences between polyester and nylon directly affect their moisture absorption, thermal properties, and fabric applications in textiles and industrial uses.

Manufacturing Processes

Polyester is produced through a chemical reaction involving purified terephthalic acid (PTA) and monoethylene glycol (MEG) in a process called polymerization, followed by melting and extrusion into fibers. Nylon manufacturing involves the polymerization of diamines and dicarboxylic acids, commonly hexamethylene diamine and adipic acid, forming long molecular chains that are then spun into fibers. Understanding these distinct manufacturing processes helps you choose the fabric based on desired durability, elasticity, and moisture-wicking properties.

Key Physical Properties

Polyester offers excellent resistance to stretching and shrinking, maintaining its shape well under various conditions, while nylon provides superior elasticity and a higher strength-to-weight ratio. Both fibers exhibit strong abrasion resistance, but nylon typically outperforms polyester in durability and moisture-wicking capabilities. Choosing between polyester and nylon depends on your specific needs for flexibility, strength, and moisture management in textiles or outdoor gear.

Durability and Strength Comparison

Polyester and nylon both offer high durability, but nylon generally provides greater tensile strength and better abrasion resistance, making it ideal for heavy-duty applications. Polyester excels in resisting UV damage and maintaining structural integrity in wet conditions, offering longevity in outdoor use. Nylon fibers absorb more water, which can reduce strength when wet, whereas polyester retains strength and dries faster, enhancing its durability in moist environments.

Moisture Absorption and Breathability

Polyester exhibits low moisture absorption, allowing it to dry quickly but often trapping heat and reducing breathability. Nylon absorbs slightly more moisture than polyester, enhancing comfort by improving air circulation and breathability during physical activities. Both fibers are durable, but nylon's superior moisture-wicking properties make it preferable for activewear demanding better ventilation.

Applications in Textile and Industry

Polyester and nylon are extensively used in textile and industrial applications due to their durability and versatility. Polyester is favored for upholstery, outdoor fabrics, and activewear because of its moisture resistance and UV stability, while nylon excels in hosiery, parachutes, and tire reinforcements due to its exceptional strength and elasticity. Both fibers contribute significantly to manufacturing automotive parts, conveyor belts, and industrial filters, demonstrating their importance across diverse sectors.

Environmental Impact and Sustainability

Polyester is derived from petroleum and has a higher carbon footprint due to energy-intensive production, while nylon also relies on fossil fuels but typically uses more water and emits nitrous oxide, a potent greenhouse gas. Both fabrics are non-biodegradable and contribute to microplastic pollution in oceans, but recycled polyester (rPET) offers a more sustainable alternative by reducing waste and energy consumption. Your choice for sustainable textiles should consider the source material and end-of-life impact to minimize environmental harm.

Cost and Availability

Polyester generally offers a lower cost and wider availability compared to nylon, making it a budget-friendly option for textiles and manufacturing. Nylon tends to be more expensive due to its complex production process and is less commonly found in general retail markets. Your choice between polyester and nylon will impact both the budget and accessibility of materials for your project.

Choosing Between Polyester and Nylon

Polyester offers greater UV resistance and color retention, making it ideal for outdoor applications, while nylon provides superior strength and elasticity, suitable for high-performance gear. Both fibers are durable and water-resistant, but nylon tends to absorb more moisture, impacting drying times. Selecting between polyester and nylon depends on the desired balance of durability, moisture management, and application-specific requirements.

Polyester vs Nylon Infographic

libmatt.com

libmatt.com