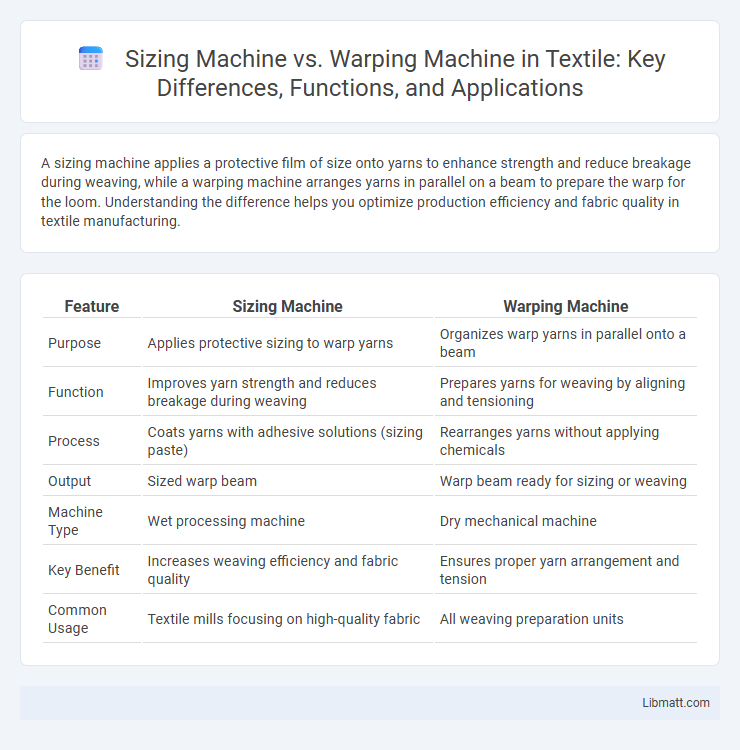

A sizing machine applies a protective film of size onto yarns to enhance strength and reduce breakage during weaving, while a warping machine arranges yarns in parallel on a beam to prepare the warp for the loom. Understanding the difference helps you optimize production efficiency and fabric quality in textile manufacturing.

Table of Comparison

| Feature | Sizing Machine | Warping Machine |

|---|---|---|

| Purpose | Applies protective sizing to warp yarns | Organizes warp yarns in parallel onto a beam |

| Function | Improves yarn strength and reduces breakage during weaving | Prepares yarns for weaving by aligning and tensioning |

| Process | Coats yarns with adhesive solutions (sizing paste) | Rearranges yarns without applying chemicals |

| Output | Sized warp beam | Warp beam ready for sizing or weaving |

| Machine Type | Wet processing machine | Dry mechanical machine |

| Key Benefit | Increases weaving efficiency and fabric quality | Ensures proper yarn arrangement and tension |

| Common Usage | Textile mills focusing on high-quality fabric | All weaving preparation units |

Introduction to Sizing and Warping Machines

Sizing machines apply protective coatings to yarns, enhancing tensile strength and abrasion resistance before weaving, crucial for maintaining fabric quality. Warping machines organize yarns into parallel bundles on beams, preparing them for the weaving process by ensuring uniform tension and alignment. Both machines are essential in textile manufacturing, optimizing yarn properties and arrangement for efficient loom operation.

Key Functions of Sizing Machines

Sizing machines apply a protective adhesive coating to yarns, enhancing their strength and reducing breakage during weaving. They improve fabric quality by ensuring uniform yarn tension and smoothness, which minimizes warp defects. Your textile production benefits from sizing machines by increasing efficiency and reducing downtime caused by yarn damage.

Main Purpose of Warping Machines

Warping machines primarily focus on preparing yarns by aligning and winding them onto a warp beam, ensuring uniform tension and organization for weaving. This process establishes the foundational structure of warp threads, crucial for the fabric's strength and pattern accuracy. Your fabric's quality heavily depends on the precise performance of the warping machine before it reaches the sizing stage.

Process Differences: Sizing vs Warping

Sizing machines apply a protective adhesive coating to warp yarns, enhancing their strength and reducing breakage during weaving, whereas warping machines arrange yarns in parallel order onto a warp beam without additional treatment. The sizing process involves the application, drying, and heat-setting of size agents, while warping focuses on precisely measuring and aligning yarns based on fabric specifications. Sizing is crucial for yarn durability, whereas warping ensures proper yarn tension and layout for efficient loom operation.

Components and Materials Used

Sizing machines primarily utilize rollers, drying chambers, and tanks designed to apply sizing agents like starch or synthetic polymers to yarns, often incorporating stainless steel and heat-resistant materials to withstand high temperatures and chemical exposure. Warping machines consist of creels, beams, tension devices, and guide bars, typically made from durable metals such as aluminum or steel, engineered to align and wind yarns onto warp beams efficiently without damage. Choosing between these machines depends on Your production needs, as sizing machines enhance yarn strength and smoothness before weaving, while warping machines focus on organizing yarns precisely for the loom.

Advantages of Sizing Machines

Sizing machines enhance yarn strength and abrasion resistance by applying a protective film, reducing breakage during weaving processes. These machines improve fabric quality and consistency through uniform sizing application, leading to increased production efficiency. Energy-efficient designs and advanced tension control systems in sizing machines minimize waste and operational costs compared to traditional warping machines.

Benefits of Warping Machines

Warping machines enhance yarn alignment and tension control, resulting in improved fabric uniformity and reduced defects during weaving. They increase production efficiency by preparing multiple yarn ends simultaneously, minimizing machine downtime. The consistent tension from warping machines also extends the lifespan of weaving equipment and lowers maintenance costs.

Applications in Textile Manufacturing

Sizing machines enhance yarn strength and reduce breakage by applying protective coatings before weaving, essential for warp yarn preparation in textile manufacturing. Warping machines organize and align yarns into beams, ensuring consistent tension and structure critical for the weaving process. Both machines are integral to efficient fabric production, each targeting specific stages in preparing yarns for weaving.

Efficiency and Productivity Comparison

Sizing machines enhance yarn strength and reduce breakage during weaving, directly improving fabric quality and machine efficiency by minimizing downtime. Warping machines organize yarns onto the warp beam, enabling rapid setup for weaving but typically require more manual adjustment, affecting overall productivity. Your choice depends on whether optimizing yarn durability (sizing) or accelerating loom preparation (warping) aligns best with your production priorities.

Choosing Between Sizing and Warping Machines

Choosing between sizing and warping machines depends on the specific fabric preparation needs in your textile production process. Sizing machines apply protective coatings to warp yarns, enhancing strength and durability, while warping machines organize yarns into precise patterns on beams for weaving. Your decision should consider fabric type, production scale, and desired textile quality to optimize efficiency and product performance.

Sizing machine vs Warping machine Infographic

libmatt.com

libmatt.com