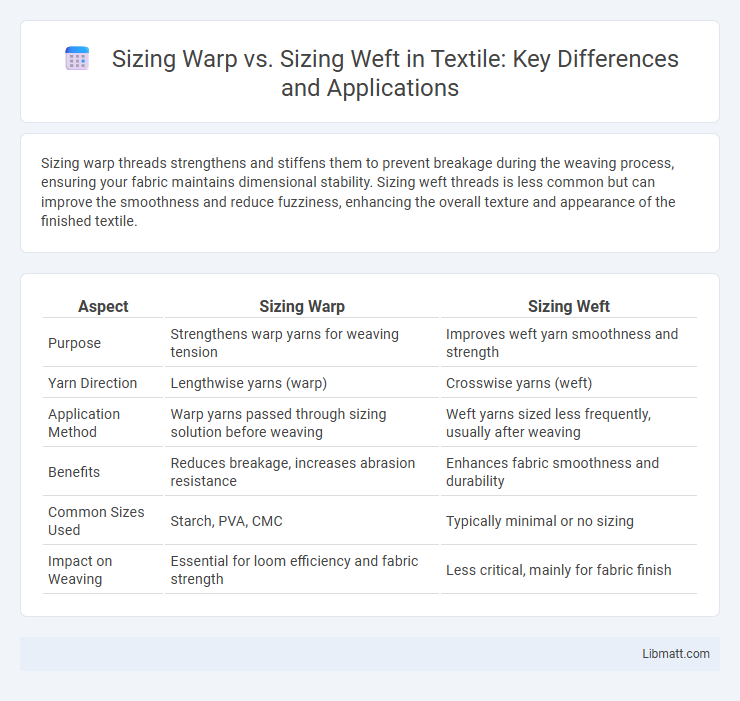

Sizing warp threads strengthens and stiffens them to prevent breakage during the weaving process, ensuring your fabric maintains dimensional stability. Sizing weft threads is less common but can improve the smoothness and reduce fuzziness, enhancing the overall texture and appearance of the finished textile.

Table of Comparison

| Aspect | Sizing Warp | Sizing Weft |

|---|---|---|

| Purpose | Strengthens warp yarns for weaving tension | Improves weft yarn smoothness and strength |

| Yarn Direction | Lengthwise yarns (warp) | Crosswise yarns (weft) |

| Application Method | Warp yarns passed through sizing solution before weaving | Weft yarns sized less frequently, usually after weaving |

| Benefits | Reduces breakage, increases abrasion resistance | Enhances fabric smoothness and durability |

| Common Sizes Used | Starch, PVA, CMC | Typically minimal or no sizing |

| Impact on Weaving | Essential for loom efficiency and fabric strength | Less critical, mainly for fabric finish |

Introduction to Sizing in Textile Manufacturing

Sizing in textile manufacturing involves applying a protective adhesive coating primarily to warp yarns to enhance their strength and abrasion resistance during weaving. Warp yarn sizing differs significantly from weft sizing due to the higher tension and continuous exposure to loom stress experienced by warp threads. Proper sizing optimizes fabric quality, reduces breakage, and improves overall weaving efficiency, emphasizing the critical role of warp sizing in production processes.

What is Sizing Warp?

Sizing warp involves applying a protective adhesive coating to the warp yarns before weaving to enhance strength, reduce breakage, and improve abrasion resistance during loom operations. This process is critical because warp yarns endure significant tension and stress, requiring a smooth, uniform coating to maintain fabric quality and weaving efficiency. Compared to sizing weft, which is less common and involves the weft yarns, warp sizing demands precise formulation and thorough application to ensure optimal performance in high-speed weaving machines.

What is Sizing Weft?

Sizing weft refers to the application of a protective adhesive coating on the weft yarns in textile production to enhance their strength and reduce friction during weaving. Unlike warp sizing, which strengthens the longitudinal threads, sizing weft specifically targets the horizontal yarns, improving overall fabric durability and uniformity. Your fabric's finish and performance significantly benefit from properly sized weft threads, ensuring smoother loom operation and minimizing yarn breakage.

Key Differences Between Sizing Warp and Sizing Weft

Sizing warp involves applying protective coatings to warp yarns, enhancing strength and abrasion resistance during weaving, whereas sizing weft focuses on stabilizing weft yarns to reduce friction and breakage. Warp sizing typically uses stronger, more viscous agents due to warp yarns bearing higher tension, while weft sizing employs lighter formulations to maintain fabric flexibility. These key differences in application and formulation optimize yarn performance and fabric quality in the weaving process.

Importance of Sizing Warp Yarns

Sizing warp yarns is crucial because warp threads endure significant tension during weaving, requiring enhanced strength and reduced abrasion. Proper sizing minimizes yarn breakage and improves fabric quality by providing smoothness and uniformity essential for efficient loom performance. Your fabric's durability and appearance largely depend on the effectiveness of warp yarn sizing compared to the relatively less critical sizing of weft yarns.

Importance of Sizing Weft Yarns

Sizing weft yarns enhances fabric strength and abrasion resistance by improving their dimensional stability during weaving. Unlike warp sizing, which primarily supports tension, sizing weft yarns minimizes float and retraction, ensuring uniform fabric texture and minimizing defects. Properly sized weft yarns contribute to improved fabric performance and reduced breakage rates in high-speed weaving machines.

Materials Used in Warp Sizing vs. Weft Sizing

Sizing warp involves applying stronger, more durable materials such as starch, PVA (polyvinyl alcohol), or acrylics to enhance yarn strength and abrasion resistance during weaving. Weft sizing often uses lighter, less adhesive substances since weft yarns experience less tension, allowing for easier penetration and flexibility. Your choice of sizing materials directly impacts fabric quality, with warp sizing prioritizing durability and weft sizing balancing smoothness and flexibility.

Application Techniques: Warp Sizing vs. Weft Sizing

Warp sizing typically involves applying a protective adhesive coating to yarns before they are woven, using techniques like size box coating, spraying, or foam application to enhance tensile strength and reduce breakage during weaving. Weft sizing is less common and often applied through localized methods such as padding or brushing to improve weft yarn cohesion and abrasion resistance after weaving. The selection of warp versus weft sizing techniques depends on yarn type, weaving machinery, and desired fabric performance characteristics.

Effects on Fabric Quality: Warp vs. Weft Sizing

Sizing warp yarns enhances fabric strength and abrasion resistance, improving dimensional stability and reducing weaving defects. Weft sizing, though less common, can also increase fabric smoothness and reduce pilling, but its impact on tensile strength is generally lower compared to warp sizing. The differential sizing of warp and weft yarns directly influences fabric uniformity, hand feel, and overall durability, critical factors in textile performance and quality control.

Conclusion: Choosing the Right Sizing Method

Sizing warp yarns enhances tensile strength and abrasion resistance, critical for weaving durability, while sizing weft yarns improves fabric stability and reduces shrinkage. Your choice should align with the fabric's end-use, machinery type, and desired quality attributes to optimize performance and cost-efficiency. Evaluating the balance between warp and weft sizing ensures tailored production outcomes for specific textile applications.

Sizing warp vs Sizing weft Infographic

libmatt.com

libmatt.com