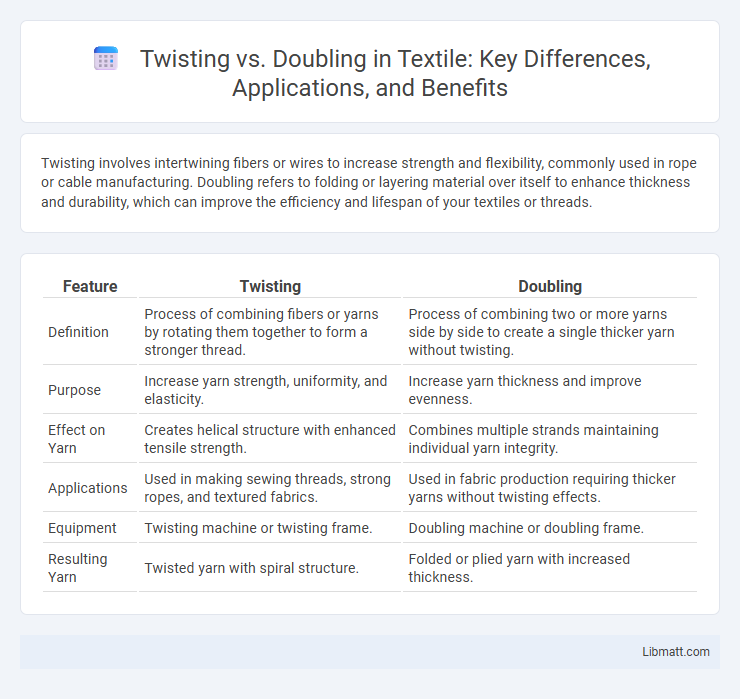

Twisting involves intertwining fibers or wires to increase strength and flexibility, commonly used in rope or cable manufacturing. Doubling refers to folding or layering material over itself to enhance thickness and durability, which can improve the efficiency and lifespan of your textiles or threads.

Table of Comparison

| Feature | Twisting | Doubling |

|---|---|---|

| Definition | Process of combining fibers or yarns by rotating them together to form a stronger thread. | Process of combining two or more yarns side by side to create a single thicker yarn without twisting. |

| Purpose | Increase yarn strength, uniformity, and elasticity. | Increase yarn thickness and improve evenness. |

| Effect on Yarn | Creates helical structure with enhanced tensile strength. | Combines multiple strands maintaining individual yarn integrity. |

| Applications | Used in making sewing threads, strong ropes, and textured fabrics. | Used in fabric production requiring thicker yarns without twisting effects. |

| Equipment | Twisting machine or twisting frame. | Doubling machine or doubling frame. |

| Resulting Yarn | Twisted yarn with spiral structure. | Folded or plied yarn with increased thickness. |

Introduction to Twisting and Doubling

Twisting and doubling are essential textile manufacturing processes that enhance yarn strength and uniformity. Twisting intertwines fibers to increase tensile strength, while doubling combines multiple yarns to improve consistency and volume. Understanding the difference between twisting and doubling helps optimize your fabric quality and production efficiency.

Defining Twisting: Concepts and Applications

Twisting involves intertwining two or more strands of fibers or wires to form a stronger, cohesive unit, enhancing tensile strength and flexibility in materials like ropes, cables, and textiles. This mechanical process optimizes load distribution and resistance to wear, making it essential in industrial applications such as electrical wiring, climbing ropes, and fabric manufacturing. Twisting improves structural integrity by aligning fibers for enhanced performance in both synthetic and natural materials.

What is Doubling? A Clear Explanation

Doubling is a textile process where two or more slivers of fiber are combined and drawn out together to improve uniformity, strength, and consistency in the yarn. This technique reduces unevenness and enhances the quality of the final product, making it essential in producing smooth, durable yarns for weaving and knitting. Understanding doubling helps you optimize fiber preparation for superior fabric performance.

Key Differences Between Twisting and Doubling

Twisting involves intertwining multiple fibers or yarns to create a single stronger thread, primarily enhancing strength and elasticity, while doubling refers to combining two or more strands side by side without twisting to increase thickness and uniformity. Twisting affects the yarn's tensile strength and texture, making it more durable for applications like weaving and knitting, whereas doubling mainly impacts the yarn's weight and consistency for smoother fabric production. The key difference lies in twisting modifying the yarn's structural integrity through torque, whereas doubling simply layers yarns together to achieve desired thickness.

Benefits of Twisting in Practice

Twisting in practice enhances yarn strength by interlocking fibers more tightly, resulting in improved durability and resistance to wear. This process also promotes better elasticity, allowing textiles to maintain shape and comfort under stress. The increased cohesion from twisting reduces fiber slippage, leading to higher-quality fabrics suitable for diverse applications.

Advantages of Doubling Techniques

Doubling techniques enhance yarn strength and uniformity by combining multiple fibers, resulting in improved durability and reduced breakage during weaving or knitting processes. This method also allows for finer control over yarn thickness and texture, optimizing fabric quality for various textile applications. Increased production efficiency and material savings are achieved by minimizing waste and facilitating smoother downstream processing.

Common Uses of Twisting vs Doubling

Twisting and doubling are essential processes in textile manufacturing, where twisting is commonly used to enhance yarn strength and create textured patterns in fabrics like ropes, sewing threads, and knitting yarns. Doubling combines multiple yarns to improve thickness, uniformity, and durability, frequently applied in producing heavier textiles such as upholstery, denim, and industrial fabrics. Your choice between twisting and doubling depends on the desired fabric characteristics and specific application requirements.

Factors to Consider When Choosing Twisting or Doubling

Choosing between twisting and doubling depends on the desired yarn strength, texture, and end-use application. Twisting is ideal for creating strong, durable yarns with enhanced elasticity, while doubling combines multiple strands to increase thickness and uniformity. Your decision should consider fiber type, yarn thickness requirements, and the final product's performance needs.

Latest Trends in Twisting and Doubling

Latest trends in twisting and doubling emphasize enhanced precision and automation with advanced machinery to improve yarn strength and uniformity. Integration of real-time monitoring systems and AI-driven analytics allows manufacturers to optimize twist levels and doubling ratios for diverse textile applications. Sustainable practices are also gaining traction, focusing on energy-efficient processes and eco-friendly materials in twisting and doubling operations.

Conclusion: Twisting vs Doubling—Which Is Better?

Twisting fibers enhances yarn strength and elasticity by interlocking strands into a cohesive structure, ideal for applications requiring durability and stretch. Doubling increases yarn thickness and uniformity by combining fibers without additional stress, suited for producing bulkier, even threads. Choosing between twisting and doubling depends on the specific textile requirement, with twisting favored for tensile strength and doubling preferred for achieving consistent yarn weight.

Twisting vs Doubling Infographic

libmatt.com

libmatt.com