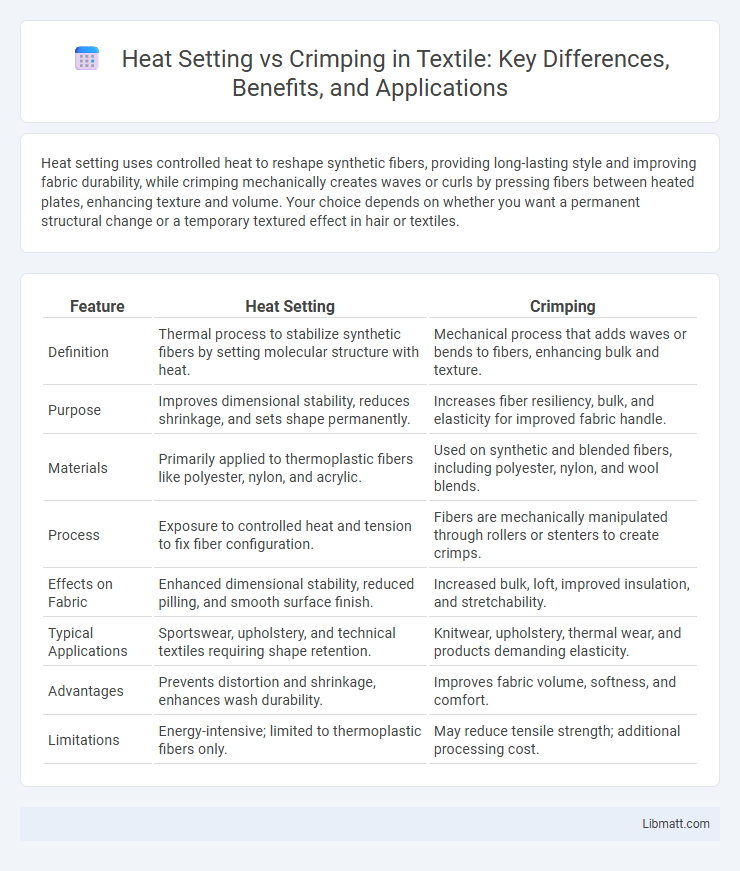

Heat setting uses controlled heat to reshape synthetic fibers, providing long-lasting style and improving fabric durability, while crimping mechanically creates waves or curls by pressing fibers between heated plates, enhancing texture and volume. Your choice depends on whether you want a permanent structural change or a temporary textured effect in hair or textiles.

Table of Comparison

| Feature | Heat Setting | Crimping |

|---|---|---|

| Definition | Thermal process to stabilize synthetic fibers by setting molecular structure with heat. | Mechanical process that adds waves or bends to fibers, enhancing bulk and texture. |

| Purpose | Improves dimensional stability, reduces shrinkage, and sets shape permanently. | Increases fiber resiliency, bulk, and elasticity for improved fabric handle. |

| Materials | Primarily applied to thermoplastic fibers like polyester, nylon, and acrylic. | Used on synthetic and blended fibers, including polyester, nylon, and wool blends. |

| Process | Exposure to controlled heat and tension to fix fiber configuration. | Fibers are mechanically manipulated through rollers or stenters to create crimps. |

| Effects on Fabric | Enhanced dimensional stability, reduced pilling, and smooth surface finish. | Increased bulk, loft, improved insulation, and stretchability. |

| Typical Applications | Sportswear, upholstery, and technical textiles requiring shape retention. | Knitwear, upholstery, thermal wear, and products demanding elasticity. |

| Advantages | Prevents distortion and shrinkage, enhances wash durability. | Improves fabric volume, softness, and comfort. |

| Limitations | Energy-intensive; limited to thermoplastic fibers only. | May reduce tensile strength; additional processing cost. |

Introduction to Heat Setting and Crimping

Heat setting is a thermal process used to stabilize synthetic fibers by applying heat to lock molecular chains in place, enhancing fabric durability and wrinkle resistance. Crimping involves mechanically creating permanent waves or bends in fibers to increase bulk, elasticity, and insulation properties of textiles. Both techniques optimize fiber performance but differ in method and end-use applications within the textile industry.

What is Heat Setting?

Heat setting is a process used to stabilize the shape and texture of synthetic fibers by applying controlled heat, which locks the fibers into a desired form. This technique enhances the durability and resilience of textiles, preventing deformation during use or laundering. Your fabrics gain improved dimensional stability and a longer-lasting appearance through precise heat setting methods.

What is Crimping?

Crimping is a mechanical process that joins two pieces of metal or other ductile materials by deforming one or both to hold the other. It is commonly used in electrical work to create a secure connection between wires and terminals without the need for soldering or heat. This method ensures a reliable, conductive, and strong bond, ideal for applications requiring durability and resistance to vibration.

Key Differences Between Heat Setting and Crimping

Heat setting involves applying controlled heat to fibers to stabilize their shape and texture, enhancing fabric durability and wrinkle resistance. Crimping mechanically imparts a zigzag or wave-like pattern to fibers, increasing bulk, elasticity, and insulation properties. Your choice impacts fabric performance, with heat setting focusing on permanence and crimping enhancing volume and texture.

Benefits of Heat Setting

Heat setting enhances fiber stability by locking synthetic fibers into a fixed shape, resulting in long-lasting crease retention and fabric durability. This process reduces shrinkage and improves wrinkle resistance, making garments easier to maintain and care for. Your textiles will benefit from improved texture and shape retention, ensuring a polished appearance over time.

Advantages of Crimping

Crimping offers precise mechanical connections that ensure higher durability and resistance to vibrations, making it ideal for automotive and industrial applications. This technique eliminates the need for heat, reducing the risk of damage to heat-sensitive components and improving overall safety. Your electrical connections benefit from improved conductivity and consistent quality, enhancing long-term reliability.

Applications of Heat Setting

Heat setting is widely used in textile manufacturing to stabilize synthetic fibers like polyester and nylon, enhancing fabric dimensional stability and wrinkle resistance. It is essential in carpet production to lock in fiber shape and ensure durability under heavy foot traffic. Heat setting also plays a critical role in producing technical textiles, such as automotive upholstery and filtration materials, by improving fiber strength and maintaining desired fabric properties.

Common Uses of Crimping

Crimping is commonly used in electrical and mechanical applications to join connectors, wires, or terminals securely without soldering, ensuring reliable conductivity and mechanical stability. It is essential in automotive wiring harnesses, telecommunications cables, and HVAC systems where quick, durable connections are required. Heat setting, in contrast, primarily involves heat-activated materials and is less suited for creating permanent electrical joins compared to crimping.

Choosing the Right Method: Heat Setting vs Crimping

Choosing the right method between heat setting and crimping depends on the specific application and material properties; heat setting uses controlled heat to shape synthetic fibers permanently, ideal for creating durable curls or waves. Crimping mechanically presses the hair or fabric with patterned plates to form textured ridges, suitable for temporary styles or adding volume. Selecting heat setting offers long-lasting results on thermoplastic fibers, while crimping provides quick, reversible styling without altering fiber structure.

Conclusion: Which Process Is Best?

Heat setting provides long-lasting fiber stability by permanently altering the synthetic fiber structure through controlled temperature treatment. Crimping enhances bulk and texture by mechanically creating waves or bends without chemical changes, suitable for applications needing moderate resilience. The best process depends on desired fabric properties: heat setting for durability and shape retention, crimping for increased volume and softness.

Heat setting vs Crimping Infographic

libmatt.com

libmatt.com