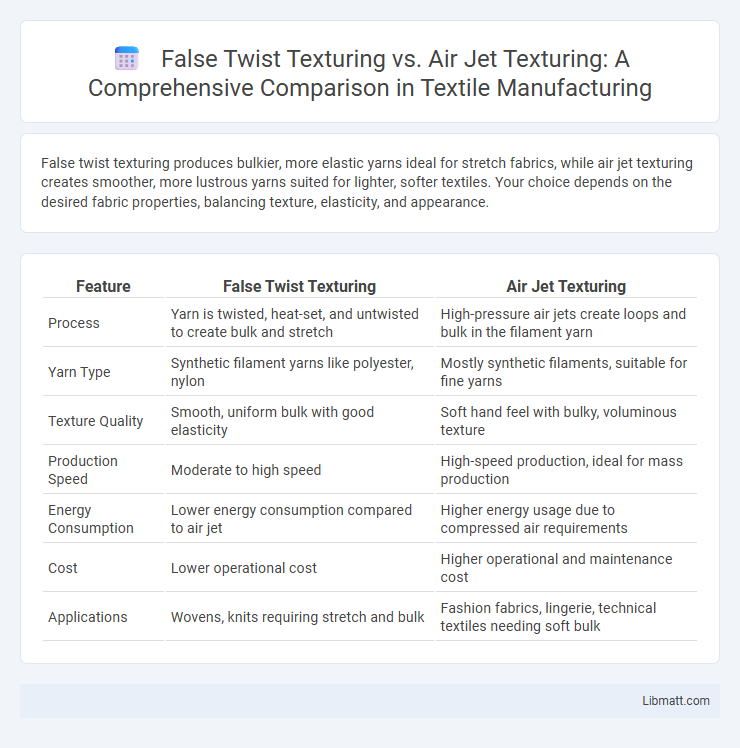

False twist texturing produces bulkier, more elastic yarns ideal for stretch fabrics, while air jet texturing creates smoother, more lustrous yarns suited for lighter, softer textiles. Your choice depends on the desired fabric properties, balancing texture, elasticity, and appearance.

Table of Comparison

| Feature | False Twist Texturing | Air Jet Texturing |

|---|---|---|

| Process | Yarn is twisted, heat-set, and untwisted to create bulk and stretch | High-pressure air jets create loops and bulk in the filament yarn |

| Yarn Type | Synthetic filament yarns like polyester, nylon | Mostly synthetic filaments, suitable for fine yarns |

| Texture Quality | Smooth, uniform bulk with good elasticity | Soft hand feel with bulky, voluminous texture |

| Production Speed | Moderate to high speed | High-speed production, ideal for mass production |

| Energy Consumption | Lower energy consumption compared to air jet | Higher energy usage due to compressed air requirements |

| Cost | Lower operational cost | Higher operational and maintenance cost |

| Applications | Wovens, knits requiring stretch and bulk | Fashion fabrics, lingerie, technical textiles needing soft bulk |

Introduction to Yarn Texturing Techniques

False twist texturing and air jet texturing are two prominent yarn texturing techniques used to enhance fabric properties such as elasticity, bulk, and appearance. False twist texturing involves mechanically twisting and heat-setting yarn to create permanent crimps, ideal for producing textured filament yarns with high durability. Air jet texturing utilizes high-pressure air to entangle fibers, resulting in soft, textured yarns with improved bulk and minimal twist, often preferred for lightweight and breathable textiles.

Understanding False Twist Texturing

False twist texturing imparts bulk, stretch, and softness to synthetic yarns by twisting the filament, heating it to set the twist, and untwisting it to create permanent crimps. This process enhances yarn elasticity and improves fabric handling properties, making it ideal for producing textured polyester and nylon fibers. Compared to air jet texturing, which uses high-pressure air to create loops and entanglements, false twist texturing provides a more uniform and resilient yarn surface.

Overview of Air Jet Texturing

Air jet texturing is a high-speed process that uses compressed air streams to entangle filaments, creating textured yarn with improved bulk and elasticity. This method offers greater uniformity and is suitable for delicate or fine fibers, providing enhanced softness and sheen in the final fabric. Your textile products benefit from air jet texturing's efficient production and consistent yarn quality, ideal for lightweight and stretchable fabrics.

Process Comparison: False Twist vs Air Jet

False twist texturing utilizes a mechanical twisting and heat-setting process to create bulk and elasticity in synthetic yarns, making it ideal for producing textured yarns with high durability and strength. In contrast, air jet texturing employs compressed air to interlace fibers without twist, resulting in smoother, softer yarns with less bulk and enhanced uniformity. Your choice depends on whether you prioritize the stretch and resilience from false twist or the lightweight softness from air jet texturing.

Equipment and Machinery Requirements

False twist texturing machines require complex spindle-based equipment capable of quickly twisting and heat-setting synthetic filaments, demanding precision control of temperature and tension for consistent yarn quality. Air jet texturing machinery relies on high-pressure air jets to entangle filaments, necessitating robust compressors and specialized nozzles designed to create textured yarns without applying mechanical twist. Both systems require sophisticated automation and monitoring controls, but false twist machines tend to have higher energy consumption and more intricate mechanical components compared to the pneumatic-driven air jet texturing equipment.

Properties of False Twist Textured Yarns

False twist textured yarns exhibit high bulk, excellent stretch recovery, and enhanced durability due to their twisted and heat-set process. Their smooth surface and uniform texture make them ideal for applications requiring elasticity and resilience, such as activewear and upholstery. You can expect superior dimensional stability and softer hand feel compared to air jet textured yarns, which are more open and less elastic.

Characteristics of Air Jet Textured Yarns

Air jet textured yarns feature a smooth, bulky structure with a soft handle and high tensile strength, producing fabrics with excellent coverage and lightweight properties. These yarns offer uniformity, low shrinkage, and improved abrasion resistance, making them ideal for applications requiring durability and aesthetic appeal. Your choice of air jet textured yarn ensures enhanced fabric performance, particularly in activewear and home textiles.

Advantages and Limitations of Each Method

False twist texturing offers high flexibility in creating various yarn textures and is ideal for producing soft, elastic, and bulked yarns; however, it involves higher energy consumption and slower production speeds. Air jet texturing excels in rapid processing and lower energy usage, producing smooth, uniform textured yarns suitable for high-speed weaving, yet it may result in less elasticity and limited yarn types. Your choice depends on whether you prioritize yarn diversity and elasticity or production efficiency and smoother yarn texture.

Applications in the Textile Industry

False twist texturing excels in producing bulkier, highly textured yarns ideal for knitted garments, upholstery, and sportswear due to its high-speed twisting and heat-setting process. Air jet texturing is preferred for creating smoother, softer textured yarns with enhanced elasticity, commonly used in woven fabrics, hosiery, and lingerie where lightweight and comfort are crucial. Both methods significantly impact fabric performance but cater to distinct end-use requirements within the textile industry.

Choosing the Right Texturing Method for Your Needs

False twist texturing excels in producing durable, high-quality yarns with strong bulk and elasticity, ideal for stretch fabrics and intricate designs, while air jet texturing offers faster processing rates with smoother, cleaner yarn surfaces suited for lightweight and sheer textiles. Your choice depends on factors such as fabric application, desired texture, production speed, and budget constraints. Evaluating these criteria ensures the best texturing method enhances fabric performance and meets specific manufacturing requirements.

False twist texturing vs Air jet texturing Infographic

libmatt.com

libmatt.com