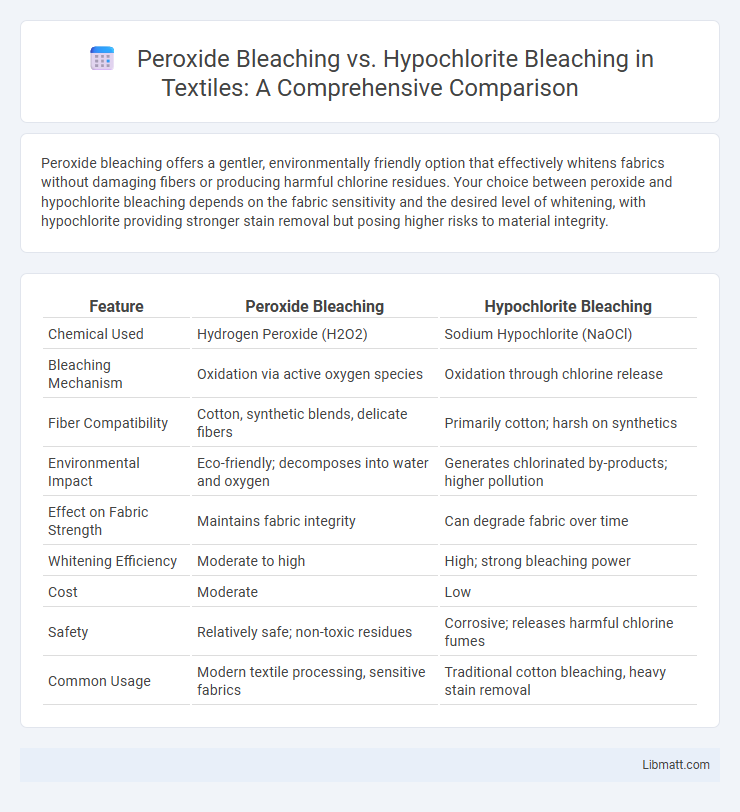

Peroxide bleaching offers a gentler, environmentally friendly option that effectively whitens fabrics without damaging fibers or producing harmful chlorine residues. Your choice between peroxide and hypochlorite bleaching depends on the fabric sensitivity and the desired level of whitening, with hypochlorite providing stronger stain removal but posing higher risks to material integrity.

Table of Comparison

| Feature | Peroxide Bleaching | Hypochlorite Bleaching |

|---|---|---|

| Chemical Used | Hydrogen Peroxide (H2O2) | Sodium Hypochlorite (NaOCl) |

| Bleaching Mechanism | Oxidation via active oxygen species | Oxidation through chlorine release |

| Fiber Compatibility | Cotton, synthetic blends, delicate fibers | Primarily cotton; harsh on synthetics |

| Environmental Impact | Eco-friendly; decomposes into water and oxygen | Generates chlorinated by-products; higher pollution |

| Effect on Fabric Strength | Maintains fabric integrity | Can degrade fabric over time |

| Whitening Efficiency | Moderate to high | High; strong bleaching power |

| Cost | Moderate | Low |

| Safety | Relatively safe; non-toxic residues | Corrosive; releases harmful chlorine fumes |

| Common Usage | Modern textile processing, sensitive fabrics | Traditional cotton bleaching, heavy stain removal |

Introduction to Chemical Bleaching Agents

Peroxide bleaching and hypochlorite bleaching are prominent chemical bleaching agents used in textile and paper industries for whitening and removing color impurities. Peroxide bleaching utilizes hydrogen peroxide (H2O2), which acts as a strong oxidizing agent, offering eco-friendly and fabric-safe properties. Hypochlorite bleaching employs sodium hypochlorite (NaOCl), known for its powerful bleaching effect but associated with potential fiber damage and environmental concerns due to chlorine by-products.

Overview of Peroxide Bleaching

Peroxide bleaching uses hydrogen peroxide as an environmentally friendly oxidizing agent to whiten textiles and paper without producing harmful chlorinated byproducts. This method excels in preserving fabric strength and brightness, making it ideal for sensitive materials and sustainable manufacturing processes. Your choice of peroxide bleaching supports eco-conscious production due to its reduced impact on water pollution compared to hypochlorite bleaching.

Overview of Hypochlorite Bleaching

Hypochlorite bleaching utilizes sodium hypochlorite as a strong oxidizing agent to effectively remove color impurities and whiten textiles, paper, and other materials. This method is highly efficient in decolorizing but can cause fiber damage and environmental concerns due to the release of chlorinated compounds. Understanding the chemical properties of hypochlorite helps you balance bleaching performance with material safety and sustainability requirements.

Mechanisms of Bleaching Action

Peroxide bleaching works through the release of active oxygen that breaks down chromophores, effectively whitening materials without damaging fibers. Hypochlorite bleaching involves chlorine-based compounds that oxidize stains by disrupting molecular structures, which can sometimes weaken the fabric. You can choose peroxide bleaching for a gentler, more environmentally friendly option and hypochlorite bleaching for stronger stain removal on durable textiles.

Comparative Effectiveness on Different Substrates

Peroxide bleaching exhibits superior effectiveness on delicate substrates such as textiles and paper, offering brightening without significant fiber damage due to its mild oxidative action. Hypochlorite bleaching delivers rapid and powerful stain removal, proving more effective on heavily soiled or durable materials like cotton and industrial fabrics but may cause fiber weakening and discoloration. Selecting between peroxide and hypochlorite bleaching depends on substrate sensitivity, with peroxide preferred for preserving material integrity and hypochlorite utilized for aggressive cleaning tasks.

Environmental Impact and Sustainability

Peroxide bleaching generates water and oxygen as byproducts, making it environmentally friendly and highly sustainable compared to hypochlorite bleaching, which releases harmful chlorinated compounds and produces toxic effluents that can contaminate water sources. Choosing peroxide bleaching helps reduce your ecological footprint by minimizing hazardous waste and supporting cleaner production processes. This approach aligns with sustainable industry practices by conserving resources and protecting ecosystems from chemical pollution.

Health and Safety Considerations

Peroxide bleaching is generally safer than hypochlorite bleaching due to its lower toxicity and reduced risk of releasing harmful chlorine gas, posing fewer health hazards in handling and disposal. Hypochlorite bleaching can cause skin and respiratory irritation, and improper use may lead to exposure to toxic chlorine compounds, necessitating stricter safety protocols. When choosing a bleaching method, your health and safety risks are minimized with peroxide, making it a preferred option in environments requiring safer chemical handling.

Cost Efficiency and Industrial Applications

Peroxide bleaching offers superior cost efficiency in textile and paper industries due to lower chemical consumption and reduced environmental compliance costs compared to hypochlorite bleaching. Hypochlorite bleaching, while effective for rapid disinfection and whitening in pulp and water treatment, incurs higher expenses from corrosion management and hazardous waste disposal. Industrial applications favor peroxide bleaching for sustainable processes in cotton and synthetic fibers, whereas hypochlorite remains prevalent in short-cycle cleaning and sterilization where immediate oxidative power is critical.

Whitening Quality and Fabric Integrity

Peroxide bleaching offers superior whitening quality with a bright, clean finish while preserving fabric integrity due to its gentle chemical action, making it ideal for delicate textiles. Hypochlorite bleaching delivers strong whitening effects but can compromise fabric strength and cause yellowing or fiber damage over time. Choosing peroxide bleaching ensures your fabrics maintain their durability and appearance without harsh degradation.

Future Trends in Textile Bleaching Technologies

Emerging trends in textile bleaching show a significant shift towards eco-friendly alternatives, with peroxide bleaching gaining popularity due to its lower environmental impact compared to hypochlorite bleaching. Innovations in enzyme-assisted peroxide bleaching and advanced catalysis methods are enhancing efficiency while reducing chemical usage and waste. Your choice of bleaching technology will likely benefit from ongoing developments aimed at sustainability and improved fabric quality.

Peroxide Bleaching vs Hypochlorite Bleaching Infographic

libmatt.com

libmatt.com