Twill tape offers a soft, flexible texture ideal for reinforcing seams and edges, while grosgrain provides a firm, ribbed appearance perfect for decorative trims and sturdy applications. Choosing between the two depends on whether your project requires durability or a polished, structured look.

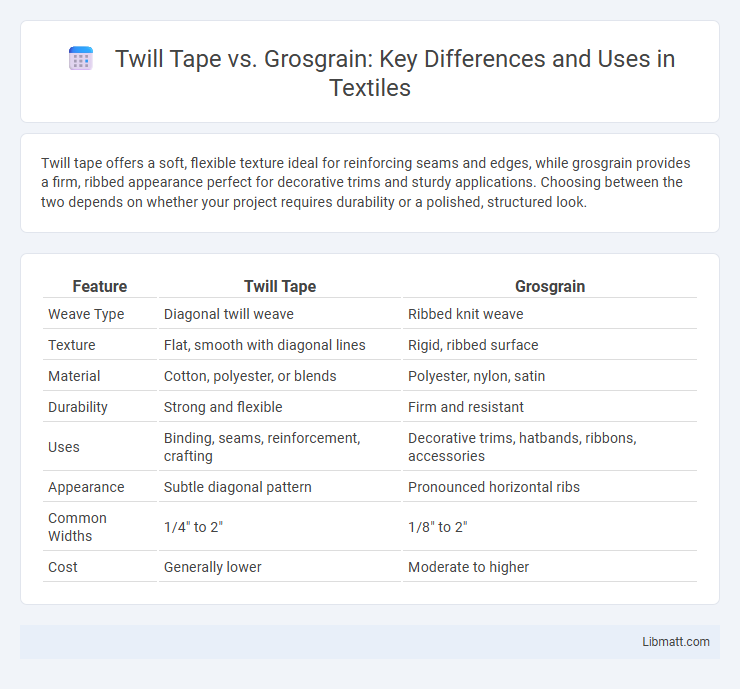

Table of Comparison

| Feature | Twill Tape | Grosgrain |

|---|---|---|

| Weave Type | Diagonal twill weave | Ribbed knit weave |

| Texture | Flat, smooth with diagonal lines | Rigid, ribbed surface |

| Material | Cotton, polyester, or blends | Polyester, nylon, satin |

| Durability | Strong and flexible | Firm and resistant |

| Uses | Binding, seams, reinforcement, crafting | Decorative trims, hatbands, ribbons, accessories |

| Appearance | Subtle diagonal pattern | Pronounced horizontal ribs |

| Common Widths | 1/4" to 2" | 1/8" to 2" |

| Cost | Generally lower | Moderate to higher |

Introduction to Twill Tape and Grosgrain

Twill tape is a narrow, woven fabric strip characterized by its diagonal weave pattern, typically made from cotton, polyester, or cotton-poly blends, and is widely used for reinforcing seams, binding edges, and creating durable ties. Grosgrain ribbon features a distinct ribbed texture with closely spaced horizontal ridges, made from silk, nylon, or polyester, commonly utilized in garment trims, hatbands, and crafting for its stiffness and decorative appeal. Both materials serve unique functional and aesthetic roles in sewing and fashion industries, offering varying levels of durability, flexibility, and visual texture.

Material Composition and Manufacturing

Twill tape is typically made from cotton, polyester, or a blend, featuring a distinctive diagonal weave that provides flexibility and durability, while grosgrain is woven from heavier fibers like silk, nylon, or polyester to create pronounced, ribbed ribs that offer stiffness and texture. The manufacturing process for twill tape involves a simpler weave pattern that results in a flatter, softer tape ideal for binding and sewing, whereas grosgrain's complex weaving produces a firm, resilient ribbon often used for trims and garment accents. When selecting between Twill tape and Grosgrain for your project, consider the desired texture and strength based on their material composition and weave structure.

Texture and Appearance Differences

Twill tape features a flat, diagonal weave that creates a smooth texture with subtle ridges, imparting a classic, understated appearance ideal for binding and reinforcing edges. Grosgrain ribbon is characterized by its pronounced ribbed texture with closely spaced horizontal ribs, giving it a more textured and visually striking look often used in decorative applications like bows and trims. The distinct weave patterns result in twill tape having a softer, more flexible feel compared to the stiffer, sturdier nature of grosgrain.

Common Uses in Sewing and Crafts

Twill tape is commonly used for reinforcing seams, binding edges, and creating durable straps or ties in sewing projects due to its flat weave and sturdy texture. Grosgrain ribbon, characterized by its ribbed appearance and slight stiffness, is favored for decorative trims, hair accessories, and garment embellishments that require a structured yet flexible material. Both materials serve distinct functional and aesthetic purposes in crafting, with twill tape prioritizing strength and grosgrain emphasizing decorative appeal.

Durability and Strength Comparison

Twill tape offers exceptional durability due to its tight diagonal weave, making it highly resistant to wear and tear, while grosgrain features a heavier ribbed texture that provides strong structural integrity and resistance to stretching. Your choice between the two depends on the specific application, as twill tape excels in flexibility and strength for binding and reinforcing seams, whereas grosgrain is preferred for decorative trims requiring a firm, resilient finish. When strength under stress and longevity are critical, twill tape generally outperforms grosgrain in durability despite grosgrain's robust appearance.

Flexibility and Handling

Twill tape offers superior flexibility and a softer hand, making it ideal for applications requiring ease of manipulation and a smooth finish. Grosgrain ribbon is stiffer and holds its shape better, providing structure and durability in projects where crisp edges and firm handling are essential. The choice between twill tape and grosgrain depends on the need for pliability versus rigidity in sewing, crafting, or garment construction.

Color and Pattern Availability

Twill tape typically offers a limited range of solid colors, emphasizing muted tones and subtle patterns due to its diagonal weave structure. Grosgrain ribbon stands out with a diverse palette and extensive pattern options, including stripes, polka dots, and custom prints, making it more versatile for creative projects. Your choice depends on whether you prioritize understated elegance or vibrant, patterned designs.

Cost and Accessibility

Twill tape is generally more affordable and widely accessible due to its simple weave and availability in various fabrics, making it ideal for budget-conscious projects. Grosgrain, featuring a more textured ribbed pattern, tends to cost more and may be found primarily in specialty craft stores or fabric outlets. You can easily source twill tape online or in most fabric shops, while grosgrain might require extra effort to find specific colors or widths.

Tips for Choosing Between Twill Tape and Grosgrain

When choosing between twill tape and grosgrain, consider the material's texture and durability for your project needs; twill tape offers a softer, more flexible feel ideal for garment seams and binding, while grosgrain features a ribbed texture providing greater stiffness suitable for decorative trims and bows. Evaluate the width and weight requirements, as twill tape comes in narrower, lightweight versions for subtle finishes, whereas grosgrain is available in wider, sturdier forms for structural support. Assess colorfastness and availability in specific colors to match designs accurately, since grosgrain often has vibrant, fade-resistant hues, and twill tape may require pre-washing to prevent shrinking.

Frequently Asked Questions

Twill tape is a flat, tightly woven fabric strip often made from cotton, polyester, or a blend, known for its durability and flexibility in sewing and binding applications, whereas grosgrain features a heavily ribbed texture with a tighter weave, made primarily from silk or synthetic fibers, prized for its stiffness and decorative use in ribbons and trims. Frequently asked questions highlight differences in texture, usage, and durability, with users often asking which tape is better suited for garment reinforcement, crafting, or upholstery projects. Both materials offer unique qualities: twill tape excels in strength and ease of sewing, while grosgrain stands out for resistance to fraying and aesthetic appeal in fashion accessories.

Twill tape vs Grosgrain Infographic

libmatt.com

libmatt.com