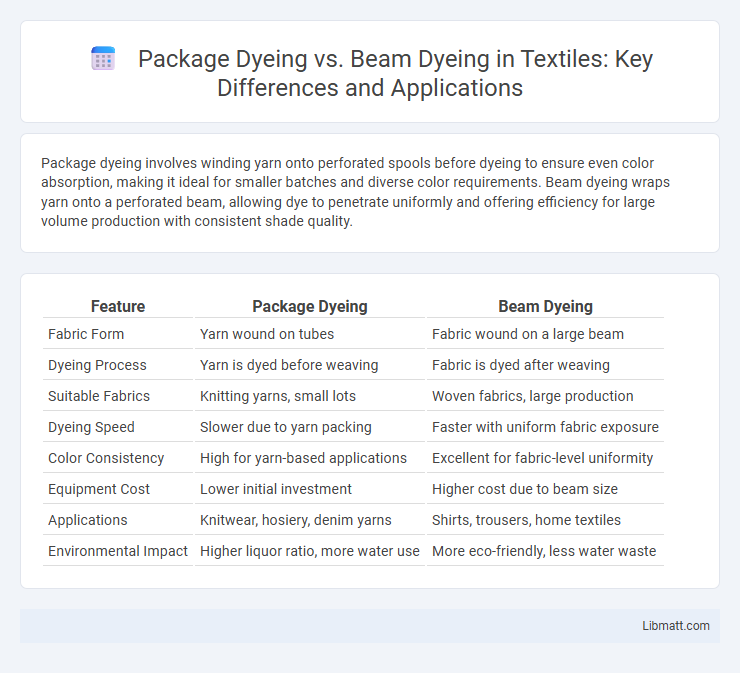

Package dyeing involves winding yarn onto perforated spools before dyeing to ensure even color absorption, making it ideal for smaller batches and diverse color requirements. Beam dyeing wraps yarn onto a perforated beam, allowing dye to penetrate uniformly and offering efficiency for large volume production with consistent shade quality.

Table of Comparison

| Feature | Package Dyeing | Beam Dyeing |

|---|---|---|

| Fabric Form | Yarn wound on tubes | Fabric wound on a large beam |

| Dyeing Process | Yarn is dyed before weaving | Fabric is dyed after weaving |

| Suitable Fabrics | Knitting yarns, small lots | Woven fabrics, large production |

| Dyeing Speed | Slower due to yarn packing | Faster with uniform fabric exposure |

| Color Consistency | High for yarn-based applications | Excellent for fabric-level uniformity |

| Equipment Cost | Lower initial investment | Higher cost due to beam size |

| Applications | Knitwear, hosiery, denim yarns | Shirts, trousers, home textiles |

| Environmental Impact | Higher liquor ratio, more water use | More eco-friendly, less water waste |

Introduction to Package Dyeing and Beam Dyeing

Package dyeing involves tightly wound yarns on perforated spools, allowing dye liquor to penetrate evenly for uniform color results. Beam dyeing uses a large cylindrical beam holding warp yarns under tension, enabling efficient dyeing of long continuous yarn lengths with minimal entanglement. Your choice between package dyeing and beam dyeing impacts fabric quality, production speed, and dyeing uniformity in textile manufacturing.

Overview of Dyeing Processes

Package dyeing involves dyeing textile yarns wound on perforated spools, allowing dye liquor to penetrate through the yarn package for uniform color application. Beam dyeing uses large perforated cylindrical beams holding wound warp yarns, enabling dye to flow through yarn layers under controlled temperature and pressure for consistent dye uptake. Both methods optimize dye penetration and color fastness but differ in equipment design and suitability for yarn types and fabric production processes.

Key Differences Between Package and Beam Dyeing

Package dyeing involves winding yarn into cylindrical packages and dyeing them under pressure, allowing even penetration but higher tension, while beam dyeing wraps yarn around perforated beams for gentle dyeing with less tension and less risk of yarn damage. Package dyeing suits shorter yarn lengths and offers faster processing but can cause more tangling, whereas beam dyeing is ideal for longer yarns, providing uniform dyeing and reduced yarn stress. The choice hinges on yarn type, fabric requirements, and production scale, with package dyeing being common in denim and beam dyeing preferred for delicate or high-quality yarns.

Machinery Used in Package vs Beam Dyeing

Package dyeing utilizes cylindrical perforated tubes where yarn is wound tightly, requiring specialized package dyeing machines equipped with precise tension control and high-pressure dye circulation systems. Beam dyeing employs large cylindrical beams holding yarn wound under low tension, necessitating beam dyeing machines designed for uniform dye penetration through controlled liquor flow and pressure regulation. Your choice between package and beam dyeing machinery depends on factors like yarn type, desired dye uniformity, and production scale.

Process Efficiency and Productivity Comparison

Package dyeing offers higher productivity for short to medium-length yarn batches due to its faster dye penetration and simpler setup, while beam dyeing excels in process efficiency for long and continuous yarn lengths by enabling uniform dyeing with less mechanical stress. Beam dyeing reduces fabric tension and energy consumption, leading to lower processing costs and improved dye consistency. The choice between the two methods depends on batch size and production goals, with package dyeing favored for flexibility and beam dyeing for large-scale uniformity.

Color Consistency and Dye Penetration

Package dyeing offers superior dye penetration due to the yarn being tightly wound, allowing your fibers to absorb color more evenly and resulting in consistent hues throughout the material. Beam dyeing, while faster for high-volume runs, tends to provide less uniform color consistency because the dye may not penetrate as deeply into tightly packed yarn layers. Choosing package dyeing enhances the vibrancy and longevity of your textile's color, ensuring a more reliable and uniform finish.

Suitable Applications for Each Dyeing Method

Package dyeing is suitable for short to medium-length yarns and small to medium production batches, making it ideal for textiles requiring vibrant and consistent colors such as cotton and blended yarns. Beam dyeing is preferred for long yarn lengths and large-scale production runs, especially for synthetic and fine yarns, providing uniform dye penetration and reduced yarn tension. Your choice depends on production volume and yarn type, with package dyeing favoring flexibility and beam dyeing excelling in efficiency and quality for high-volume processing.

Environmental Impact: Water and Energy Usage

Package dyeing consumes significantly more water and energy due to the high liquor ratio and longer processing times compared to beam dyeing. Beam dyeing uses a smaller amount of water, up to 80% less, and more efficient circulation methods that reduce energy consumption during the dyeing process. Consequently, beam dyeing is recognized as an environmentally sustainable alternative with lower carbon emissions and wastewater generation.

Cost Implications and Economic Considerations

Package dyeing generally incurs higher costs due to longer processing times, increased labor, and greater energy consumption, making it less economical for large production runs. Beam dyeing offers significant cost savings by enabling faster dyeing of wound fabric on a beam, reducing water usage and minimizing waste, which benefits Your bottom line in industrial-scale operations. Selecting beam dyeing can optimize economic efficiency, especially when managing bulk fabric volumes and aiming to lower per-yard dyeing expenses.

Choosing the Right Dyeing Method for Your Needs

Package dyeing offers deep, uniform color penetration ideal for high-volume yarn batches, while beam dyeing is more efficient for delicate, fine yarns, minimizing tension and damage. Your choice depends on fabric type, production scale, and desired colorfastness, with package dyeing suited for durable, evenly dyed textiles and beam dyeing for lightweight, sensitive materials. Understanding these differences ensures optimal dye quality and process efficiency tailored to your manufacturing requirements.

Package dyeing vs Beam dyeing Infographic

libmatt.com

libmatt.com