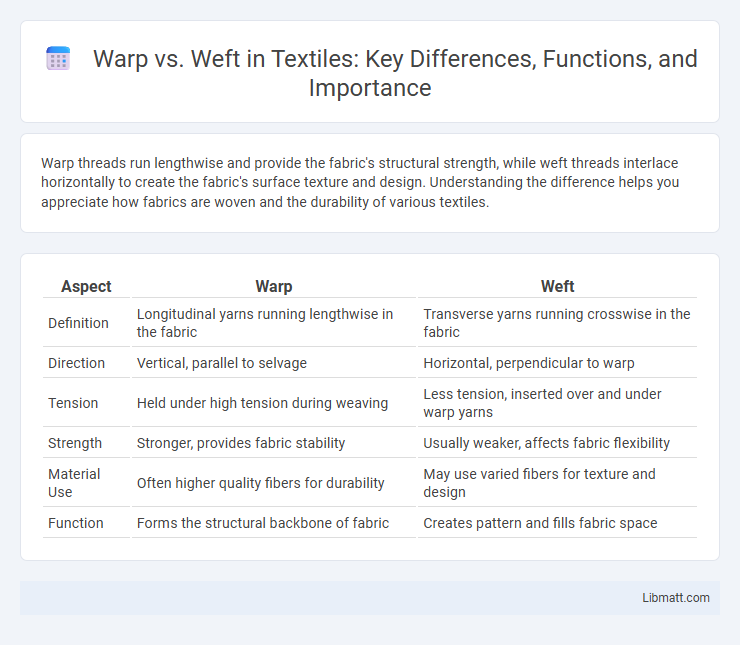

Warp threads run lengthwise and provide the fabric's structural strength, while weft threads interlace horizontally to create the fabric's surface texture and design. Understanding the difference helps you appreciate how fabrics are woven and the durability of various textiles.

Table of Comparison

| Aspect | Warp | Weft |

|---|---|---|

| Definition | Longitudinal yarns running lengthwise in the fabric | Transverse yarns running crosswise in the fabric |

| Direction | Vertical, parallel to selvage | Horizontal, perpendicular to warp |

| Tension | Held under high tension during weaving | Less tension, inserted over and under warp yarns |

| Strength | Stronger, provides fabric stability | Usually weaker, affects fabric flexibility |

| Material Use | Often higher quality fibers for durability | May use varied fibers for texture and design |

| Function | Forms the structural backbone of fabric | Creates pattern and fills fabric space |

Introduction to Warp and Weft

Warp threads run vertically and form the foundational structure in weaving, providing strength and stability to the fabric. Weft threads interlace horizontally, crossing over and under the warp to create the fabric's pattern and texture. Understanding the distinction between warp and weft is essential in textile production and fabric design.

Defining Warp and Weft in Textiles

Warp threads run vertically along the loom, providing the structural foundation for woven textiles, essential for fabric strength and stability. Weft threads interlace horizontally with the warp, weaving back and forth to create the fabric's pattern and texture. Understanding the distinct roles of warp and weft is crucial for textile manufacturing, influencing durability and design complexity.

Historical Significance of Warp and Weft

Warp and weft threads have shaped textile production since ancient civilizations, with evidence of their use dating back over 5,000 years in regions like Mesopotamia and Egypt. The warp provides the foundational structure, while the weft interlaces to create durable and intricate fabrics essential for clothing, trade, and cultural identity. Understanding these roles reveals how your textiles carry centuries of craftsmanship and heritage woven into every thread.

Key Differences Between Warp and Weft

Warp threads run lengthwise along the fabric, providing structural strength and stability by remaining taut during weaving. Weft threads are woven crosswise through the warp, creating the fabric's pattern and texture by interlacing horizontally. Understanding the distinction between warp and weft helps you identify fabric characteristics like durability and flexibility essential for textile design.

Types of Fibers Used for Warp and Weft

Warp threads typically require strong, durable fibers such as cotton, linen, or polyester to withstand tension during weaving, while weft fibers can be more varied and softer, including wool, silk, or rayon, to add texture and flexibility. You should consider that warp fibers need superior tensile strength and stability, often making natural or synthetic fibers with high elongation resistance ideal. Weft fibers complement the warp by enhancing the fabric's aesthetic and comfort, allowing a broader choice of fiber types depending on the desired end-use of the textile.

Weaving Techniques: Warp vs Weft

Warp threads run vertically on a loom and provide the structural foundation for weaving, while weft threads are woven horizontally over and under the warp to create the fabric. Your choice of weaving technique affects the texture, strength, and design of the textile, with warp threads typically being stronger to maintain tension. Understanding the interplay between warp and weft is essential for crafting durable, visually appealing fabrics in various textile applications.

Strength and Durability: Warp vs Weft

Warp fibers run longitudinally along the loom and are typically stronger and more durable due to higher tension during weaving, providing structural integrity to the fabric. Weft fibers, woven horizontally across the warp, generally experience less stress and are more flexible but less resistant to tearing and wear. The interplay between warp's tensile strength and weft's flexibility determines the overall fabric durability and performance.

Applications in Modern Textiles

Warp fibers run lengthwise and provide structural strength, while weft fibers interlace crosswise, offering flexibility and design versatility in modern textiles. Your choice between warp and weft influences fabric durability, stretch, and pattern intricacy, crucial for applications in sportswear, upholstery, and performance fabrics. Optimizing warp and weft combinations enhances comfort, aesthetics, and technical performance in contemporary textile engineering.

Common Myths About Warp and Weft

Common myths about warp and weft often confuse their roles, with many assuming the warp threads run horizontally and the weft vertically, when in fact, the warp runs lengthwise on the loom while the weft threads weave crosswise. Another misconception is that only the weft determines fabric design, whereas both warp and weft interact to create the pattern and texture. Understanding these fundamentals helps you accurately identify and manipulate textile structure for better fabric creation and analysis.

Choosing the Right Yarn: Warp or Weft?

Choosing the right yarn for warp or weft depends on strength and flexibility requirements, as warp yarns must be strong and tightly twisted to withstand tension during weaving, while weft yarns can be softer and more elastic for comfort and texture. Cotton or linen yarns are often preferred for warp due to their durability, whereas wool or acrylic yarns work well for weft to add warmth and softness. Understanding these differences ensures your fabric achieves the desired balance of resilience and appearance for your project.

Warp vs Weft Infographic

libmatt.com

libmatt.com