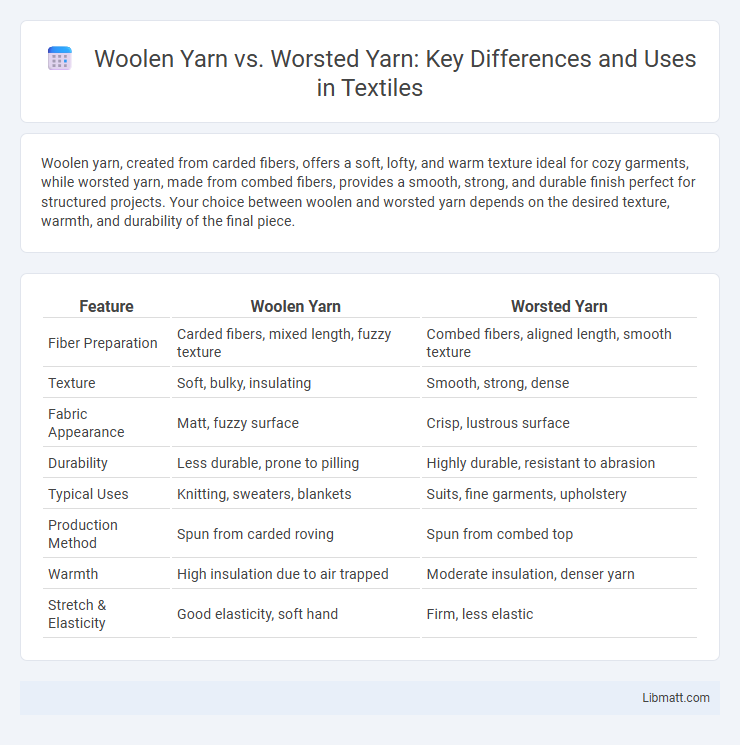

Woolen yarn, created from carded fibers, offers a soft, lofty, and warm texture ideal for cozy garments, while worsted yarn, made from combed fibers, provides a smooth, strong, and durable finish perfect for structured projects. Your choice between woolen and worsted yarn depends on the desired texture, warmth, and durability of the final piece.

Table of Comparison

| Feature | Woolen Yarn | Worsted Yarn |

|---|---|---|

| Fiber Preparation | Carded fibers, mixed length, fuzzy texture | Combed fibers, aligned length, smooth texture |

| Texture | Soft, bulky, insulating | Smooth, strong, dense |

| Fabric Appearance | Matt, fuzzy surface | Crisp, lustrous surface |

| Durability | Less durable, prone to pilling | Highly durable, resistant to abrasion |

| Typical Uses | Knitting, sweaters, blankets | Suits, fine garments, upholstery |

| Production Method | Spun from carded roving | Spun from combed top |

| Warmth | High insulation due to air trapped | Moderate insulation, denser yarn |

| Stretch & Elasticity | Good elasticity, soft hand | Firm, less elastic |

Introduction to Woolen and Worsted Yarn

Woolen yarn is spun from carded fibers that are short and fuzzy, creating a soft, warm, and insulating texture ideal for cozy sweaters and blankets. Worsted yarn, produced from combed fibers that are long and smooth, results in a strong, durable, and smooth yarn commonly used for fine garments like suits and tailored clothing. The spinning process and fiber preparation differentiate woolen from worsted yarn, influencing their texture, strength, and end-product applications.

Defining Woolen Yarn

Woolen yarn is created from carded wool fibers that are short and randomly aligned, resulting in a soft, warm, and fluffy texture ideal for insulation. Its looser spun fibers trap more air, providing enhanced warmth compared to worsted yarn, which is smoother and more tightly spun. Your choice of woolen yarn suits cozy garments or accessories where softness and thermal insulation are priorities.

Defining Worsted Yarn

Worsted yarn is defined by its smooth, fine texture achieved through a combing process that aligns long fibers parallel before spinning, resulting in strong, durable yarn with minimal fuzziness. Unlike woolen yarn, which is carded and has a softer, loftier feel with more air trapped inside, worsted yarn is denser and ideal for projects requiring crisp stitch definition and long-lasting wear. If your project demands clarity in pattern and a polished finish, worsted yarn offers superior performance and resilience.

Key Differences in Yarn Structure

Woolen yarn features a loosely spun structure with short, fluffy fibers that trap air, resulting in a soft, warm, and bulky texture ideal for insulating garments. Worsted yarn is tightly spun using long fibers aligned parallel, producing a smooth, strong, and durable yarn with a sleek appearance suited for fine knitting and weaving. Understanding these key structural differences helps you choose the right yarn for your project's texture, warmth, and durability requirements.

Preparation and Spinning Processes

Woolen yarn is produced from carded fibers that remain loosely aligned, resulting in a soft, airy texture ideal for insulation. Worsted yarn undergoes combing to remove shorter fibers and align strands parallel, creating a smooth, strong, and fine yarn suited for durable fabrics. Your choice depends on the desired fabric characteristics, with woolen offering bulk and warmth, while worsted provides strength and a sleek finish.

Characteristics and Texture Comparison

Woolen yarn is characterized by its soft, fluffy texture with fibers that are carded but not combed, resulting in a loftier, insulating fabric ideal for warmth. Worsted yarn undergoes combing processes to align fibers parallel, producing a smoother, stronger, and finer yarn with a sleek, durable texture suitable for tailored garments. The difference in fiber preparation gives woolen yarn a bulkier hand and more air retention, whereas worsted yarn offers a firmer, more lustrous finish with less bulk.

Common Applications and Uses

Woolen yarn is commonly used in products that require softness and warmth, such as sweaters, scarves, and blankets, due to its loosely spun fibers that trap air for insulation. Worsted yarn, characterized by tightly spun, smooth fibers, is preferred for durable, fine-textured garments like suits, dress pants, and tailored coats that demand strength and a polished finish. Both yarn types cater to distinct textile needs, with woolen yarn favored in cozy, casual wear and worsted yarn ideal for structured, formal clothing.

Durability and Performance

Worsted yarn, spun from long-staple fibers tightly twisted, offers superior durability and strength compared to woolen yarn, which is made from shorter fibers and a looser spin. This structural difference allows worsted yarn to perform better in applications requiring abrasion resistance and longevity, such as tailored garments and upholstery. Woolen yarn's softer texture provides warmth and elasticity but tends to be less durable under heavy wear or frequent washing.

Pros and Cons of Each Yarn Type

Woolen yarn offers superior warmth and softness due to its loosely spun fibers and air-trapping loft, making it ideal for cozy garments, but it can be prone to pilling and less durability. Worsted yarn features tightly spun, smooth fibers that provide strength, durability, and a sleek finish, suitable for tailored clothing, though it may lack the insulating qualities and softness of woolen yarn. Choosing between woolen and worsted yarn hinges on balancing the need for warmth and texture versus durability and a polished appearance.

Choosing the Right Yarn for Your Project

Woolen yarn has a soft, fluffy texture due to its short, carded fibers, making it ideal for warm, cozy garments like sweaters and scarves that require insulation and a rustic look. Worsted yarn is tightly spun with long, combed fibers, producing a smooth, durable fabric perfect for projects needing structure and stitch definition, such as tailored suits or detailed knitting patterns. Choosing between woolen and worsted yarn depends on whether your project prioritizes warmth and softness or strength and clarity in the finished piece.

Woolen Yarn vs Worsted Yarn Infographic

libmatt.com

libmatt.com