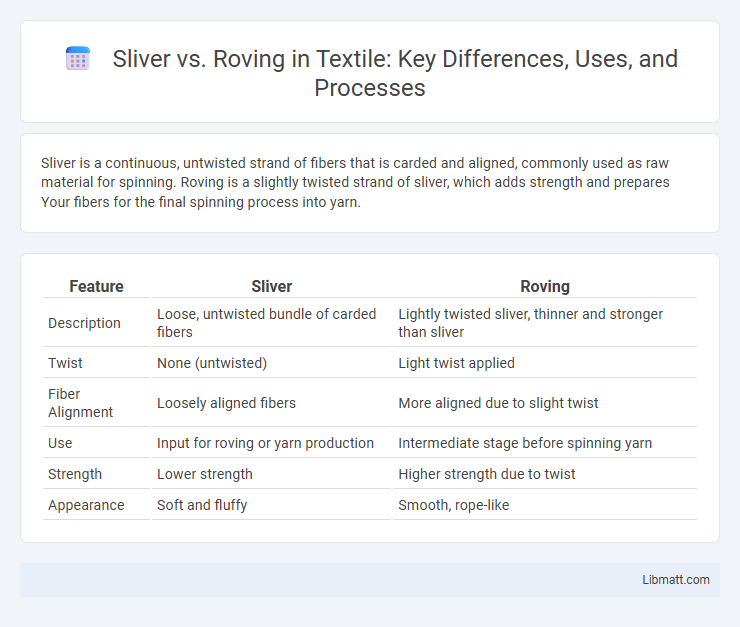

Sliver is a continuous, untwisted strand of fibers that is carded and aligned, commonly used as raw material for spinning. Roving is a slightly twisted strand of sliver, which adds strength and prepares Your fibers for the final spinning process into yarn.

Table of Comparison

| Feature | Sliver | Roving |

|---|---|---|

| Description | Loose, untwisted bundle of carded fibers | Lightly twisted sliver, thinner and stronger than sliver |

| Twist | None (untwisted) | Light twist applied |

| Fiber Alignment | Loosely aligned fibers | More aligned due to slight twist |

| Use | Input for roving or yarn production | Intermediate stage before spinning yarn |

| Strength | Lower strength | Higher strength due to twist |

| Appearance | Soft and fluffy | Smooth, rope-like |

Introduction to Sliver and Roving

Sliver and roving are crucial intermediate products in the textile manufacturing process, derived from carded fibers aligned into a loose, continuous strand. Sliver is a soft, untwisted fiber bundle that maintains parallel fibers for further processing, while roving is a slightly twisted, thinner strand created by drawing out and adding a light twist to the sliver, preparing it for spinning. Understanding the differences between sliver and roving helps optimize your yarn quality and efficiency in spinning operations.

Definitions: What is Sliver?

Sliver is a continuous bundle of loosely twisted fibers produced after carding, used as the raw material for subsequent stages of spinning. It typically measures uniform thickness and is essential for ensuring consistent yarn quality. Unlike roving, sliver remains untwisted or lightly drawn out, maintaining fiber alignment for efficient processing.

Definitions: What is Roving?

Roving is a long, narrow bundle of fiber that has been drawn out and slightly twisted to hold the strands together, used primarily in spinning and textile production. Unlike sliver, which is untwisted and thick, roving provides more strength and control for your spinning wheel or machine to create yarn. Its uniform thickness and slight twist make roving ideal for producing consistent, high-quality yarns.

Key Differences Between Sliver and Roving

Sliver and roving are both intermediate products in the textile fiber processing chain, with sliver being a continuous rope of loosely assembled fibers and roving being a slightly twisted version of sliver designed for further spinning. Sliver maintains a parallel alignment of fibers without twist, making it lightweight and bulky, whereas roving includes a slight twist to add strength for easier handling during spinning. Your choice between sliver and roving depends on the specific requirements of fiber strength, twist level, and processing stage in yarn production.

Manufacturing Processes of Sliver

Sliver manufacturing involves a carding process that transforms loose fibers into a continuous, untwisted strand, ensuring uniform alignment and thickness essential for high-quality yarn production. The carding machine uses fine teeth to clean and separate fibers, removing impurities and neps before the sliver is drawn through drafting rollers to enhance fiber parallelism. This process is crucial for achieving consistent sliver weight and preparing fibers for subsequent spinning or roving stages in textile manufacturing.

Manufacturing Processes of Roving

Roving manufacturing involves drawing and attenuating slivers into continuous, loosely twisted strands used for spinning or weaving, enhancing fiber alignment and uniformity. The process includes drafting the sliver through rollers and introducing a slight twist to improve handling characteristics without full yarn strength. Roving production is essential in textile mills for preparing fibers that balance strength and flexibility before final spinning.

Applications of Sliver in Textile Industry

Sliver is primarily used in the spinning process to create yarns for weaving and knitting applications, providing uniformity and strength to the final fabric. It serves as the intermediate material in textile production, facilitating the transformation of raw fibers into fine yarns suitable for apparel, home textiles, and industrial fabrics. Sliver's consistent thickness and alignment enhance the quality of carded and combed yarns, critical for high-performance textiles.

Applications of Roving in Textile Industry

Roving is widely used in the textile industry for producing yarns through spinning processes, offering uniform fiber alignment that enhances fabric strength and consistency. It serves as an intermediate product between sliver and final yarn, facilitating efficient drafting and twisting essential for weaving and knitting. Common applications include manufacturing high-quality cotton, wool, and synthetic yarns utilized in apparel, home textiles, and industrial fabrics.

Quality Factors: Sliver vs Roving

Sliver offers higher uniformity and consistency in fiber alignment, enhancing the quality for fine spinning processes, while roving provides slightly thicker and more twisted strands suited for preliminary yarn production. The reduced twist in sliver minimizes fiber damage and allows for smoother drafting, leading to superior strength and evenness in the final yarn. Your choice between sliver and roving should depend on the desired yarn quality and the specific requirements of the textile manufacturing stage.

Choosing the Right Intermediate: Sliver or Roving?

Selecting the appropriate intermediate in fiber processing depends on the desired yarn characteristics and spinning technique precision. Sliver, a loose, untwisted bundle of fibers, offers greater flexibility for hand spinning and finer yarn production, while roving includes a slight twist that enhances strength and makes it suitable for machine spinning and bulkier yarns. Understanding the specific requirements of the final product and the spinning method helps in choosing between sliver and roving for optimal fiber alignment and efficiency.

Sliver vs Roving Infographic

libmatt.com

libmatt.com