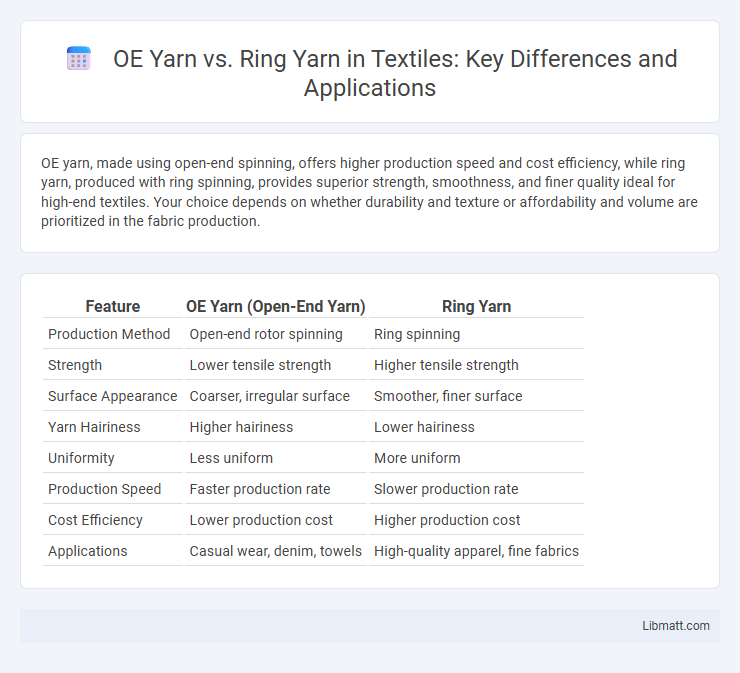

OE yarn, made using open-end spinning, offers higher production speed and cost efficiency, while ring yarn, produced with ring spinning, provides superior strength, smoothness, and finer quality ideal for high-end textiles. Your choice depends on whether durability and texture or affordability and volume are prioritized in the fabric production.

Table of Comparison

| Feature | OE Yarn (Open-End Yarn) | Ring Yarn |

|---|---|---|

| Production Method | Open-end rotor spinning | Ring spinning |

| Strength | Lower tensile strength | Higher tensile strength |

| Surface Appearance | Coarser, irregular surface | Smoother, finer surface |

| Yarn Hairiness | Higher hairiness | Lower hairiness |

| Uniformity | Less uniform | More uniform |

| Production Speed | Faster production rate | Slower production rate |

| Cost Efficiency | Lower production cost | Higher production cost |

| Applications | Casual wear, denim, towels | High-quality apparel, fine fabrics |

Introduction to OE Yarn and Ring Yarn

OE yarn, or Open-End yarn, is produced using a rotor spinning process that delivers higher production speed and coarser yarns ideal for denim and towels. Ring yarn, created through traditional ring spinning, offers finer, stronger, and smoother threads favored in high-quality textiles and garments. Understanding these differences can help you choose the right yarn type based on fabric strength, texture, and application needs.

Key Differences Between OE Yarn and Ring Yarn

OE yarn features open-end spinning technology, producing coarser, less uniform yarn ideal for denim and towels, while ring yarn uses ring spinning for finer, stronger, and smoother yarn suited for high-quality apparel. OE yarn generally offers higher productivity and lower cost but sacrifices tensile strength and surface smoothness compared to ring yarn, which exhibits superior durability and appearance. The choice between OE and ring yarn depends on the end-use requirements emphasizing texture, strength, and cost-efficiency.

Manufacturing Process of OE Yarn

OE yarn manufacturing involves an open-end rotor spinning process where fibers are fed into a rotor and spun continuously, creating yarn without the need for roving. This method allows higher production speeds and reduced labor costs compared to ring spinning, which requires drafting, twisting, and winding steps. The open-end spinning process produces yarn with a more irregular surface and lower tensile strength, making it ideal for casual wear and denim.

Manufacturing Process of Ring Yarn

The manufacturing process of Ring Yarn involves spinning fibers onto a rotating spindle using a ring and traveler mechanism, which controls yarn tension and twist for a smooth, strong, and uniform thread. This precise method creates fine, durable yarns ideal for knitting and weaving applications requiring high quality and consistency. Your choice of Ring Yarn ensures superior fabric strength and softness compared to OE yarn produced through open-end spinning.

Fiber Characteristics in OE and Ring Yarn

OE yarn features shorter fibers with a more irregular, open structure, resulting in a softer, more textured feel suitable for casual fabrics. Ring yarn uses longer, tightly twisted fibers that produce a smoother, stronger, and more durable yarn ideal for high-quality, polished textiles. Your choice between OE and Ring yarn should consider desired fabric softness versus strength and uniformity.

Strength and Durability Comparison

OE yarn offers greater strength due to its longer staple fibers and reduced fiber damage during the open-end spinning process, resulting in enhanced durability for heavy-duty textile applications. Ring yarn, characterized by its finer and more uniform fiber alignment, provides superior tensile strength and abrasion resistance, making it ideal for high-quality garments requiring softness and longevity. Your choice between OE yarn and ring yarn should consider the balance between maximum durability and fabric fineness based on the intended end use.

Applications of OE Yarn vs Ring Yarn

OE yarn, produced through open-end spinning, is widely utilized in manufacturing denim, towels, and upholstery fabrics due to its high production speed and cost efficiency. Ring yarn, known for its superior strength, smoothness, and uniformity, is predominantly applied in high-quality apparel, shirting, and knitwear where durability and finish are critical. Industrial sectors such as fashion and home textiles selectively use OE yarn for bulkier, less uniform fabrics, while ring yarn dominates premium garment production requiring finer texture and tensile strength.

Cost Considerations: OE Yarn vs Ring Yarn

OE yarn generally offers lower production costs due to higher machine speed and less labor intensity compared to ring yarn. Ring yarn, while more expensive to produce, provides superior strength and uniformity, which can justify the higher price for specialized applications. You should weigh initial cost savings of OE yarn against the quality advantages and long-term durability of ring yarn for your specific project needs.

Advantages and Disadvantages of Each Yarn Type

OE yarn offers advantages such as higher production speed and cost-effectiveness due to its open-end spinning technique, but often results in coarser texture and lower strength compared to ring yarn. Ring yarn provides superior fiber alignment and tensile strength, producing a smoother, finer fabric ideal for high-quality textiles; however, it involves slower production and higher manufacturing expenses. Choosing between OE and ring yarn depends on balancing cost efficiency against fabric quality requirements in textile production.

Choosing the Right Yarn for Your Textile Needs

OE yarn offers high production speed and cost efficiency, making it ideal for mass-produced textiles requiring consistent quality. Ring yarn, known for its strength, uniformity, and smooth finish, suits applications where durability and premium feel are essential. Understanding your project's requirements for fabric appearance, performance, and budget will guide you in choosing between OE yarn and ring yarn for optimal textile results.

OE Yarn vs Ring Yarn Infographic

libmatt.com

libmatt.com