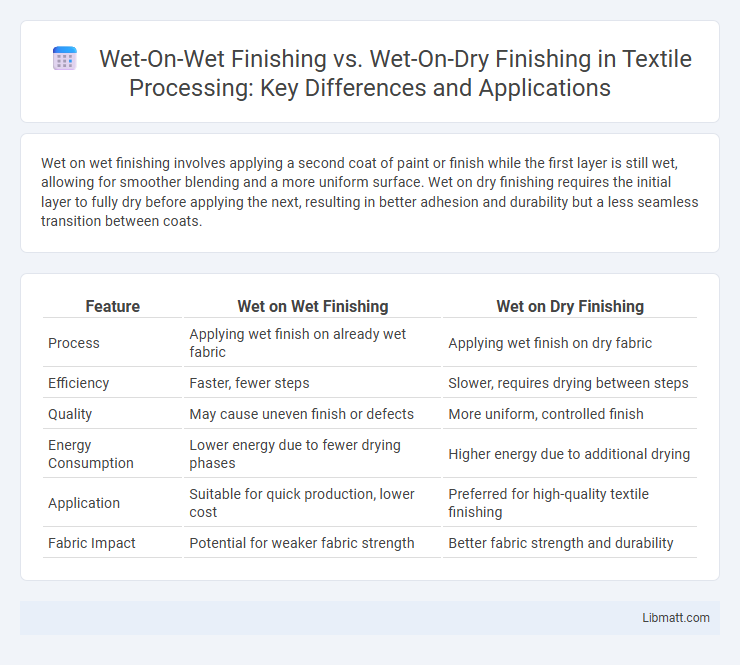

Wet on wet finishing involves applying a second coat of paint or finish while the first layer is still wet, allowing for smoother blending and a more uniform surface. Wet on dry finishing requires the initial layer to fully dry before applying the next, resulting in better adhesion and durability but a less seamless transition between coats.

Table of Comparison

| Feature | Wet on Wet Finishing | Wet on Dry Finishing |

|---|---|---|

| Process | Applying wet finish on already wet fabric | Applying wet finish on dry fabric |

| Efficiency | Faster, fewer steps | Slower, requires drying between steps |

| Quality | May cause uneven finish or defects | More uniform, controlled finish |

| Energy Consumption | Lower energy due to fewer drying phases | Higher energy due to additional drying |

| Application | Suitable for quick production, lower cost | Preferred for high-quality textile finishing |

| Fabric Impact | Potential for weaker fabric strength | Better fabric strength and durability |

Introduction to Wet on Wet and Wet on Dry Finishing

Wet on wet finishing involves applying a new layer of paint or coating directly onto a still-wet previous layer, allowing for smoother blending and faster application times, commonly used in automotive and artistic painting. Wet on dry finishing requires the initial layer to fully dry before applying subsequent coats, enhancing durability and achieving precise, sharp edges ideal for high-quality finishes. Choosing between wet on wet and wet on dry finishing impacts drying time, surface texture, and final appearance in painting and coating processes.

Understanding Wet on Wet Finishing Techniques

Wet on wet finishing techniques involve applying successive layers of finish without allowing the previous layer to dry completely, creating a smooth, blended surface ideal for achieving uniform gloss and reducing sanding between coats. This method enhances adhesion and minimizes imperfections, making it suitable for woodwork and automotive finishes where a seamless appearance is crucial. Your choice between wet on wet and wet on dry finishing depends on the desired texture, drying time, and the specific materials used.

Overview of Wet on Dry Finishing Methods

Wet on dry finishing methods involve applying a wet layer of paint, varnish, or finish over a completely dry surface, allowing for better control over texture and layering. This technique enhances adhesion and provides a more durable, even coat, ideal for detailed projects or surfaces requiring multiple layers. Your choice between wet on dry and wet on wet finishing depends on the desired finish quality and the drying time available.

Key Differences Between Wet on Wet and Wet on Dry

Wet on wet finishing involves applying a fresh coat of paint or finish onto a still-wet layer, promoting seamless blending and a smoother surface ideal for high-gloss or automotive paints. Wet on dry finishing requires waiting for the initial layer to dry completely before applying the next, resulting in better control over texture and thickness, often preferred for decorative or protective coatings. Your choice between these techniques impacts drying time, finish durability, and the final appearance of the painted surface.

Advantages of Wet on Wet Finishing

Wet on wet finishing allows for faster application by eliminating the need to wait for the first coat to dry, reducing overall project time and boosting productivity. This technique enhances paint adhesion and results in a smoother, more uniform surface by blending layers seamlessly. Your painting projects benefit from improved efficiency and a high-quality finish, particularly in professional or time-sensitive environments.

Benefits of Wet on Dry Finishing

Wet on dry finishing offers superior control and precision, allowing you to apply a second coat only after the first has fully dried, which reduces the risk of streaks and uneven texture. This method enhances durability by promoting better adhesion between layers, leading to a smoother, more resilient surface. It is ideal for achieving a high-quality, long-lasting finish on wood, paint, or varnish applications.

Common Applications for Each Finishing Method

Wet on wet finishing is commonly used in automotive painting and industrial coatings for fast turnaround projects where multiple layers need to be applied quickly without waiting for drying times. Wet on dry finishing is preferred in furniture refinishing and high-end cabinetry, where each layer is allowed to cure thoroughly for a durable, smooth surface. Both methods optimize finish quality, but wet on dry ensures better adhesion and long-lasting protection in applications requiring meticulous attention to detail.

Factors to Consider When Choosing a Finishing Technique

Choosing between wet on wet finishing and wet on dry finishing depends on factors such as drying time, surface texture, and desired durability. Wet on wet finishing requires quicker application to avoid blending issues but results in a smoother, more uniform surface, ideal for fast project completion. Your decision should also consider the compatibility of coatings and environmental conditions that affect curing and final finish quality.

Expert Tips for Achieving Optimal Results

Achieving optimal results in wet on wet finishing requires precise timing to ensure the first layer remains tacky for seamless blending, which enhances paint adhesion and reduces drying time. Wet on dry finishing, on the other hand, demands thorough drying to avoid lifting previous layers, providing a more controlled and detailed finish ideal for intricate designs. You can improve outcomes by adjusting your technique based on drying times and environmental conditions, ensuring smoother applications and longer-lasting durability.

Conclusion: Selecting the Right Finishing Method

Wet on wet finishing offers faster application and seamless blending, making it ideal for projects requiring smooth transitions and efficiency. Wet on dry finishing provides better control and durability, suitable for detailed work and surfaces needing multiple layers. Choosing the right method depends on the desired finish quality, project timeline, and surface requirements for optimal results.

Wet on wet finishing vs Wet on dry finishing Infographic

libmatt.com

libmatt.com