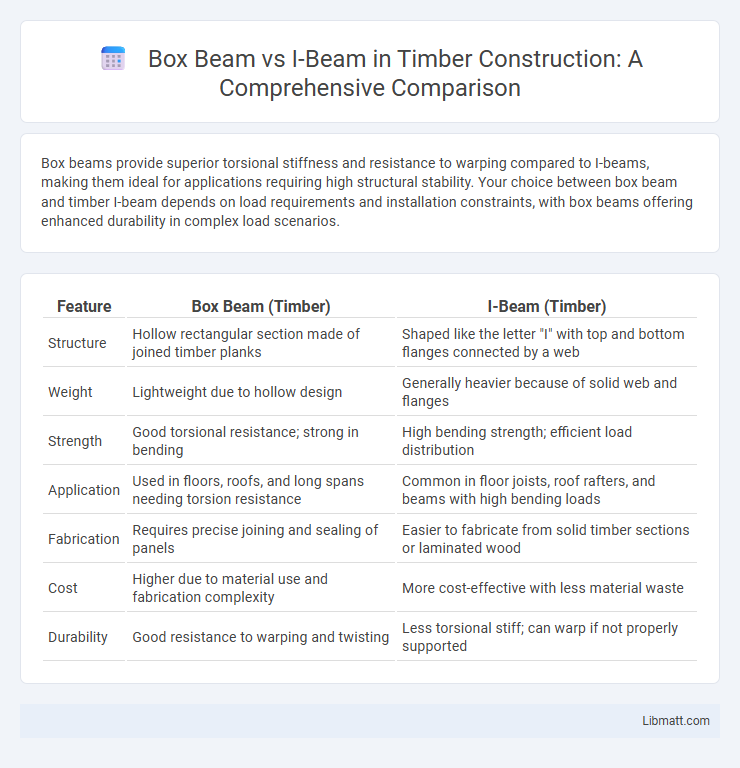

Box beams provide superior torsional stiffness and resistance to warping compared to I-beams, making them ideal for applications requiring high structural stability. Your choice between box beam and timber I-beam depends on load requirements and installation constraints, with box beams offering enhanced durability in complex load scenarios.

Table of Comparison

| Feature | Box Beam (Timber) | I-Beam (Timber) |

|---|---|---|

| Structure | Hollow rectangular section made of joined timber planks | Shaped like the letter "I" with top and bottom flanges connected by a web |

| Weight | Lightweight due to hollow design | Generally heavier because of solid web and flanges |

| Strength | Good torsional resistance; strong in bending | High bending strength; efficient load distribution |

| Application | Used in floors, roofs, and long spans needing torsion resistance | Common in floor joists, roof rafters, and beams with high bending loads |

| Fabrication | Requires precise joining and sealing of panels | Easier to fabricate from solid timber sections or laminated wood |

| Cost | Higher due to material use and fabrication complexity | More cost-effective with less material waste |

| Durability | Good resistance to warping and twisting | Less torsional stiff; can warp if not properly supported |

Introduction: Understanding Timber Beams

Timber beams are crucial structural elements in construction, with box beams and I-beams serving distinct purposes. Box beams offer enhanced torsional resistance and greater load-bearing capacity due to their hollow rectangular shape. Your choice between box beams and I-beams depends on factors like span length, load requirements, and aesthetic preferences.

Box Beam vs I-Beam: Overview

Box beams and I-beams in timber construction differ primarily in shape and load distribution, with box beams featuring a hollow rectangular profile providing exceptional torsional resistance. I-beams consist of a vertical web with horizontal flanges, optimized for bending strength and efficient material use in floor joists and beams. Your choice depends on structural requirements, where box beams excel in rigidity and I-beams offer superior bending performance and weight savings.

Structural Composition and Design

Box beams consist of four wooden panels forming a hollow rectangular shape, offering superior torsional resistance and uniform load distribution compared to I-beams. I-beams feature a vertical web and horizontal flanges that efficiently handle bending stresses, making them ideal for support in longer spans. Choosing between them depends on your structural requirements, with box beams providing enhanced stability and I-beams optimizing material use for bending loads.

Strength and Load-Bearing Capacity

Box beams offer superior strength and load-bearing capacity compared to traditional I-beams due to their enclosed rectangular cross-section, which provides enhanced resistance to bending and torsion. Timber box beams distribute loads more evenly across their surfaces, reducing stress concentrations and increasing overall structural stability. Choosing the appropriate beam type for your project ensures optimal performance and safety under heavy loads.

Weight and Material Efficiency

Box beams offer superior material efficiency compared to I-beams by enclosing a hollow rectangular section that maximizes resistance to bending and torsion while using less timber. Although box beams can be heavier due to their closed section, their enhanced stiffness and strength per unit weight often result in lighter overall structural components. Timber I-beams, with an open shape, are lighter individually but may require additional framing or bracing, decreasing material efficiency in construction.

Installation and Construction Techniques

Box beams offer easier installation due to their enclosed rectangular shape, providing greater torsional rigidity and making them ideal for supporting heavy loads with less lateral bracing. I-beams, characterized by their I-shaped cross-section, require precise alignment during construction to ensure stability and are often used where lighter, more flexible support structures are needed. Timber box beams are typically assembled using glued laminated layers for enhanced strength, while timber I-beams often combine wood flanges with engineered web materials, optimizing material usage and simplifying on-site handling.

Cost Considerations

Box beams typically offer greater strength and stability compared to I-beams, but they often come at a higher cost due to increased material and fabrication requirements. I-beams are generally more economical for projects with budget constraints, providing sufficient load-bearing capacity with less timber. Your choice should balance structural needs with cost efficiency to optimize project expenses.

Applications in Timber Construction

Box beams in timber construction provide enhanced torsional resistance and are commonly used in long-span floor systems and roof structures where stability is critical. I-beams, also known as engineered wood joists, are favored for their high strength-to-weight ratio and efficiency in residential and commercial floor framing. Both beam types optimize material use but are selected based on specific load requirements and structural design criteria.

Durability and Maintenance

Box beams offer enhanced durability compared to I-beams by providing greater resistance to twisting and warping due to their enclosed design, making them ideal for long-term structural integrity. Timber I-beams, while lighter and easier to handle, typically require more frequent maintenance to prevent issues like splitting, insect damage, and moisture intrusion. Your choice impacts maintenance frequency and overall lifespan, with box beams generally demanding less upkeep over time.

Choosing the Right Beam for Your Project

Selecting the right beam type depends on load requirements and structural design; box beams offer superior torsional resistance and aesthetic appeal due to their closed shape, making them ideal for long spans and architectural features. I-beams, commonly used in timber construction, provide efficient bending strength with less material, suitable for standard load-bearing applications. Evaluating factors such as span length, load distribution, and installation constraints ensures optimal performance and cost-effectiveness in your timber project.

Box beam vs I-Beam (Timber) Infographic

libmatt.com

libmatt.com