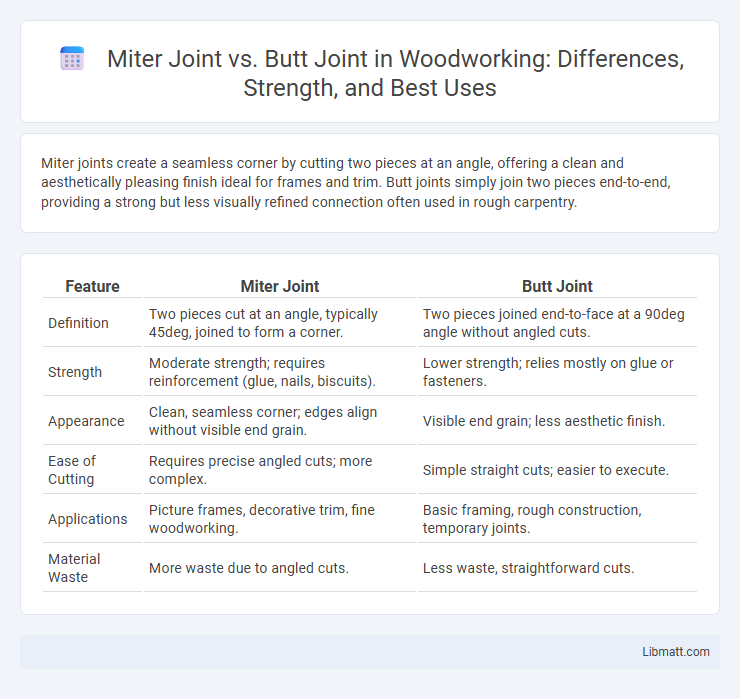

Miter joints create a seamless corner by cutting two pieces at an angle, offering a clean and aesthetically pleasing finish ideal for frames and trim. Butt joints simply join two pieces end-to-end, providing a strong but less visually refined connection often used in rough carpentry.

Table of Comparison

| Feature | Miter Joint | Butt Joint |

|---|---|---|

| Definition | Two pieces cut at an angle, typically 45deg, joined to form a corner. | Two pieces joined end-to-face at a 90deg angle without angled cuts. |

| Strength | Moderate strength; requires reinforcement (glue, nails, biscuits). | Lower strength; relies mostly on glue or fasteners. |

| Appearance | Clean, seamless corner; edges align without visible end grain. | Visible end grain; less aesthetic finish. |

| Ease of Cutting | Requires precise angled cuts; more complex. | Simple straight cuts; easier to execute. |

| Applications | Picture frames, decorative trim, fine woodworking. | Basic framing, rough construction, temporary joints. |

| Material Waste | More waste due to angled cuts. | Less waste, straightforward cuts. |

Overview of Miter Joint and Butt Joint

A miter joint connects two pieces of material at an angle, typically 45 degrees, forming a clean, polished corner often used in picture frames and moldings. A butt joint, in contrast, joins two pieces end-to-end or edge-to-edge without angle cuts, creating a straightforward and strong but less visually seamless connection. Understanding these differences helps you choose the right joint for your woodworking or framing project based on strength and aesthetic requirements.

Definition and Key Characteristics

A miter joint is formed by joining two pieces of material cut at an angle, typically 45 degrees, creating a clean, seamless corner often used in picture frames and trim work. A butt joint connects two pieces end-to-end or edge-to-face without any angled cuts, resulting in a simple, square meeting of surfaces commonly found in basic woodworking and construction. Miter joints offer enhanced aesthetics and better corner alignment, while butt joints are easier to make but generally weaker and less visually refined.

Visual Differences: Miter vs Butt Joint

Miter joints create a seamless, angled edge by joining two pieces at a 45-degree angle, resulting in a clean, professional look ideal for picture frames and trim work. Butt joints, on the other hand, involve simply butting two pieces of wood together at a 90-degree angle, producing a more straightforward and less refined appearance. Your choice between the two affects the visual appeal, with miter joints offering a polished finish while butt joints emphasize simplicity and structural function.

Strength Comparison

Miter joints typically offer less structural strength compared to butt joints because they rely heavily on adhesive or mechanical fasteners along angled cuts, which provide less surface area for bonding. Butt joints, with their square end-to-face contact, create a larger gluing surface, resulting in a stronger and more durable connection under shear and tensile stress. In woodworking and metalworking, the choice between miter and butt joints depends on the required strength and aesthetic, with butt joints favored for high-strength applications.

Common Applications for Each Joint

Miter joints are commonly used in picture frames, door and window casings, and decorative trim work due to their clean, angled edges that enhance aesthetic appeal. Butt joints find frequent application in basic framing, furniture construction, and simple box-making where structural strength is prioritized over decorative appearance. Woodworkers often select miter joints for visible corners requiring precision and butt joints for internal supports or novice woodworking projects.

Tools and Materials Required

Miter joints require precise cutting tools such as a miter saw or miter box to achieve accurate angled cuts, often using wood glue and clamps for assembly, along with nails or brads for added strength. Butt joints typically involve simpler tools like a handsaw or power saw for straight cuts, with wood glue and basic fasteners such as screws or nails being sufficient for joining the materials. Both joints may benefit from sanding tools to smooth edges and surfaces before joining.

Ease of Construction: Which Is Simpler?

A butt joint is simpler to construct compared to a miter joint because it involves joining two flat pieces of wood at a 90-degree angle without any complex cuts. Miter joints require precise 45-degree angled cuts on both pieces for the joint to fit seamlessly, making the process more intricate and time-consuming. If you're seeking ease and speed in your woodworking project, a butt joint is usually the more straightforward option.

Aesthetic Considerations

Miter joints provide a seamless, polished look by joining two pieces at a 45-degree angle, creating a clean corner that conceals end grain for enhanced visual appeal. Butt joints, formed by simply butting two pieces end-to-end, often display exposed edges, resulting in a less refined appearance unless carefully finished or reinforced. Your choice between these joints impacts the overall sophistication and smoothness of the final woodworking or framing project.

Durability and Longevity

Miter joints provide enhanced durability and longevity compared to butt joints due to their angled cuts, which increase the gluing surface area and create stronger, more stable connections. Butt joints, typically simpler and faster to make, tend to be weaker and more prone to separation under stress, especially without additional reinforcement like screws or dowels. You can ensure longer-lasting construction by choosing miter joints where aesthetics and strength are critical.

Choosing the Right Joint for Your Project

Selecting the right joint for your project depends on the desired strength and appearance; miter joints offer a clean, angled finish ideal for frames and trim but require precise cuts and reinforcement for durability. Butt joints are simpler, easier to make, and provide strong structural support when combined with glue, nails, or screws, making them suitable for basic box or carcass construction. Consider the combination of aesthetic needs and load-bearing requirements to determine whether the elegant miter joint or the robust butt joint is best for your woodworking project.

Miter joint vs Butt joint Infographic

libmatt.com

libmatt.com