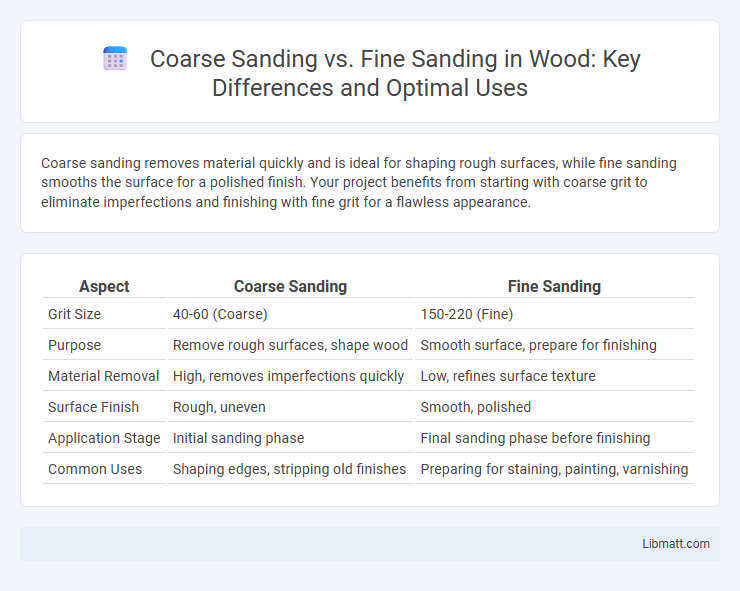

Coarse sanding removes material quickly and is ideal for shaping rough surfaces, while fine sanding smooths the surface for a polished finish. Your project benefits from starting with coarse grit to eliminate imperfections and finishing with fine grit for a flawless appearance.

Table of Comparison

| Aspect | Coarse Sanding | Fine Sanding |

|---|---|---|

| Grit Size | 40-60 (Coarse) | 150-220 (Fine) |

| Purpose | Remove rough surfaces, shape wood | Smooth surface, prepare for finishing |

| Material Removal | High, removes imperfections quickly | Low, refines surface texture |

| Surface Finish | Rough, uneven | Smooth, polished |

| Application Stage | Initial sanding phase | Final sanding phase before finishing |

| Common Uses | Shaping edges, stripping old finishes | Preparing for staining, painting, varnishing |

Understanding Coarse Sanding: Purpose and Applications

Coarse sanding involves using lower grit sandpaper, typically ranging from 40 to 60 grit, to quickly remove material, paint, or rough surfaces on wood or metal. Its primary purpose is surface leveling, shaping, and preparing rough or uneven areas for finer finishing stages. Coarse sanding is essential in heavy-duty restoration, initial woodworking stages, and preparing surfaces for subsequent fine sanding or painting.

Fine Sanding Explained: When and Why to Use It

Fine sanding refines surfaces by smoothing out imperfections left after coarse sanding, typically using higher-grit sandpaper ranging from 180 to 320 grit. It is essential for preparing surfaces for finishing touches such as painting, staining, or sealing, ensuring a flawless, even texture. Fine sanding enhances adhesion of finishes and reduces visible scratches, resulting in a polished, professional appearance.

Key Differences Between Coarse and Fine Sanding

Coarse sanding uses lower grit sandpaper (typically 40-60 grit) to quickly remove material, shape surfaces, and eliminate rough imperfections, while fine sanding employs higher grit sandpaper (usually 180-220 grit) to smooth surfaces and prepare them for finishing. Coarse sanding is essential for heavy sanding tasks such as stripping old paint or leveling uneven wood, whereas fine sanding refines the texture and ensures an even, polished appearance. The key difference lies in the grit size and the finishing stage, with coarse sanding being more abrasive and fine sanding providing a delicate, smooth finish.

Choosing the Right Sandpaper Grit for Your Project

Choosing the right sandpaper grit is essential for achieving a smooth finish and preparing surfaces effectively. Coarse sanding with grits ranging from 40 to 60 is ideal for removing old paint, shaping wood, or smoothing rough surfaces quickly. Fine sanding, using grits between 120 and 220, works best for refining surfaces, removing minor imperfections, and preparing your project for painting or staining.

Surface Preparation: Coarse vs. Fine Sanding Techniques

Coarse sanding removes larger imperfections and old finishes quickly, creating a rough surface ideal for initial preparation before applying new coatings. Fine sanding smooths out scratches left by coarse grit, refining the surface to enhance adhesion and achieve a polished, even finish. Using the appropriate grit sequence ensures optimal surface readiness for paint or stain, resulting in a professional and durable outcome.

Achieving Smooth Finishes: The Role of Fine Sanding

Fine sanding plays a critical role in achieving smooth finishes by removing minor surface imperfections left after coarse sanding. Using higher-grit sandpaper, typically ranging from 180 to 320 grit, fine sanding refines the texture and prepares the surface for painting or staining. This process enhances adhesion and ensures a flawless, professional-quality finish on wood, metal, or painted surfaces.

Common Mistakes in Coarse and Fine Sanding

Common mistakes in coarse sanding include applying excessive pressure, which can create deep scratches and uneven surfaces, while neglecting to use progressively finer grits leads to rough finishes difficult to smooth out later. In fine sanding, frequently overlooked errors involve skipping intermediate grits or sanding too aggressively, resulting in swirl marks and an uneven gloss. Proper sanding requires understanding grit progression and maintaining consistent, gentle strokes to achieve a flawless surface.

Recommended Tools for Coarse and Fine Sanding

Coarse sanding typically requires tools such as a belt sander or a coarse-grit sanding block, ideal for removing large amounts of material or smoothing rough surfaces quickly. Fine sanding is best done with a detail sander or a fine-grit sanding sponge, which helps achieve a smooth finish and prepare surfaces for painting or staining. Choosing the right tool for your coarse and fine sanding tasks ensures efficient work and a high-quality surface outcome.

Safety Tips for Coarse and Fine Sanding Processes

Use appropriate personal protective equipment like dust masks, safety goggles, and gloves to prevent inhalation of fine dust particles and protect eyes during both coarse and fine sanding. Maintain adequate ventilation in the workspace to reduce airborne dust concentration and minimize fire hazards associated with accumulated sanding debris. Regularly clean sanding tools and work areas to prevent clogging and overheating, ensuring safer and more efficient sanding operations.

Finishing Touches: Maximizing Results with Proper Sanding

Coarse sanding removes rough surfaces and imperfections, creating a smooth foundation essential for achieving flawless finishes. Fine sanding refines the surface by smoothing out scratches left by coarse grit, enhancing paint or stain adhesion for a professional look. Properly combining both techniques maximizes the durability and visual appeal of woodworking or painting projects.

Coarse sanding vs Fine sanding Infographic

libmatt.com

libmatt.com