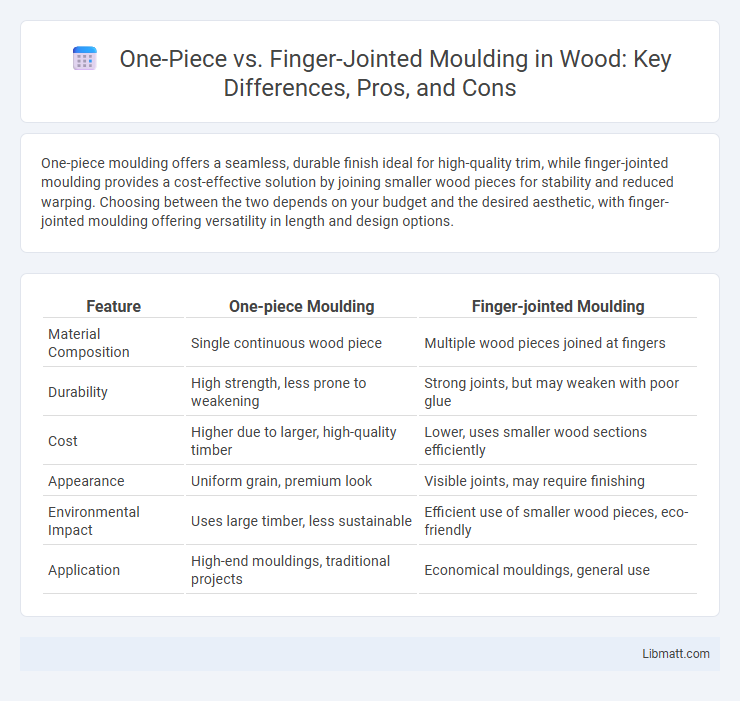

One-piece moulding offers a seamless, durable finish ideal for high-quality trim, while finger-jointed moulding provides a cost-effective solution by joining smaller wood pieces for stability and reduced warping. Choosing between the two depends on your budget and the desired aesthetic, with finger-jointed moulding offering versatility in length and design options.

Table of Comparison

| Feature | One-piece Moulding | Finger-jointed Moulding |

|---|---|---|

| Material Composition | Single continuous wood piece | Multiple wood pieces joined at fingers |

| Durability | High strength, less prone to weakening | Strong joints, but may weaken with poor glue |

| Cost | Higher due to larger, high-quality timber | Lower, uses smaller wood sections efficiently |

| Appearance | Uniform grain, premium look | Visible joints, may require finishing |

| Environmental Impact | Uses large timber, less sustainable | Efficient use of smaller wood pieces, eco-friendly |

| Application | High-end mouldings, traditional projects | Economical mouldings, general use |

Introduction to Moulding Types

One-piece moulding consists of a single continuous piece of wood, offering a seamless and smooth finish ideal for aesthetic appeal and structural integrity. Finger-jointed moulding is created by joining short wood pieces with interlocking "fingers," enhancing stability while maximizing material efficiency and reducing waste. Understanding these types helps you select the best moulding for durability, design, and cost-effectiveness in your woodworking or construction project.

What is One-Piece Moulding?

One-piece moulding is a manufacturing technique where the entire moulding profile is crafted from a single solid piece of material, often wood, providing enhanced structural integrity and a seamless appearance. This method reduces potential weak points and joints, making it more durable and visually appealing in architectural and furniture applications. Its continuous grain pattern also offers superior aesthetic qualities compared to finger-jointed moulding, which is assembled from multiple smaller pieces.

What is Finger-Jointed Moulding?

Finger-jointed moulding is a woodworking technique where short pieces of wood, cut with interlocking "fingers," are glued together to create longer, stable boards. This method enhances structural integrity by minimizing warping and ensuring consistent grain patterns, making it a reliable choice for various construction and decorative applications. Your projects benefit from finger-jointed moulding's strength and cost-efficiency compared to one-piece moulding.

Manufacturing Process Comparison

One-piece moulding is created by extruding or machining a single solid piece, resulting in uniform grain and enhanced structural integrity, while finger-jointed moulding involves joining shorter wood segments with interlocking fingers and adhesive, optimizing material usage by utilizing smaller wood pieces. The one-piece process typically requires more raw material and longer machining time but delivers higher strength and aesthetic consistency. Finger-jointed moulding manufacturing emphasizes efficiency with automated cutting and gluing systems, allowing for sustainable production with reduced waste and cost.

Durability and Strength Differences

One-piece moulding offers superior durability due to its continuous grain structure, reducing the risk of splitting and providing consistent strength along its entire length. Finger-jointed moulding, made by joining shorter wood pieces with interlocking "fingers," may have slightly lower strength but enhances material stability and reduces warping by distributing stresses. Your choice depends on the need for maximum strength in structural applications or cost-effective material use with moderate durability.

Cost and Budget Considerations

One-piece moulding typically incurs higher initial costs due to specialized machinery and material waste, making it suitable for projects with larger budgets. Finger-jointed moulding offers a cost-effective alternative by utilizing shorter wood pieces joined together, reducing material costs and minimizing waste. Budget-conscious projects often favor finger-jointed moulding for its affordability and efficient use of resources without sacrificing structural integrity.

Aesthetic Appeal and Finish Quality

One-piece moulding offers a seamless and uniform appearance, enhancing aesthetic appeal with smooth surfaces and consistent grain patterns that elevate finish quality. Finger-jointed moulding, while economical and eco-friendly, may display visible joints that can affect the uniformity of the finish but allows for efficient use of shorter wood sections. Both methods can achieve high-quality finishes, but one-piece moulding is preferred for premium applications where flawless aesthetics are critical.

Environmental Impact and Sustainability

One-piece moulding typically generates less waste as it is crafted from a single, solid section of wood, reducing the need for adhesives and minimizing offcuts. Finger-jointed moulding, made by joining smaller wood segments with adhesives, maximizes material usage by repurposing shorter wood pieces, contributing to sustainable forestry practices. Both methods can support environmental sustainability when sourced from certified sustainably managed forests, but finger-jointed moulding often offers enhanced resource efficiency through optimal wood utilization.

Common Applications and Best Uses

One-piece moulding is commonly used for decorative trim and door casings where seamless joints enhance aesthetic appeal and structural integrity. Finger-jointed moulding excels in settings requiring long lengths or intricate patterns, such as baseboards and window frames, offering superior strength and reduced material waste. Both types are favored in interior woodwork, with one-piece moulding suited for visible, high-finish applications and finger-jointed moulding ideal for cost-effective, durable installations.

How to Choose the Right Moulding for Your Project

One-piece moulding offers a seamless, sturdy finish ideal for simpler designs and shorter runs, while finger-jointed moulding provides enhanced dimensional stability and cost efficiency for longer lengths and complex projects. Consider the environmental conditions, desired aesthetic, and budget constraints when selecting between these moulding types for your project. Your choice should align with the need for durability and appearance, ensuring optimal performance throughout the lifecycle of your design.

One-piece vs finger-jointed moulding Infographic

libmatt.com

libmatt.com