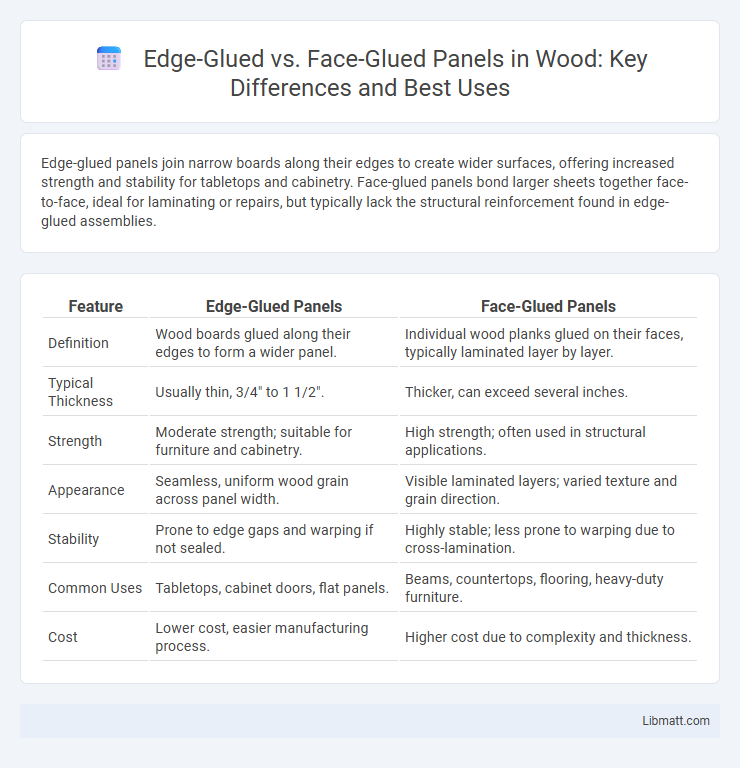

Edge-glued panels join narrow boards along their edges to create wider surfaces, offering increased strength and stability for tabletops and cabinetry. Face-glued panels bond larger sheets together face-to-face, ideal for laminating or repairs, but typically lack the structural reinforcement found in edge-glued assemblies.

Table of Comparison

| Feature | Edge-Glued Panels | Face-Glued Panels |

|---|---|---|

| Definition | Wood boards glued along their edges to form a wider panel. | Individual wood planks glued on their faces, typically laminated layer by layer. |

| Typical Thickness | Usually thin, 3/4" to 1 1/2". | Thicker, can exceed several inches. |

| Strength | Moderate strength; suitable for furniture and cabinetry. | High strength; often used in structural applications. |

| Appearance | Seamless, uniform wood grain across panel width. | Visible laminated layers; varied texture and grain direction. |

| Stability | Prone to edge gaps and warping if not sealed. | Highly stable; less prone to warping due to cross-lamination. |

| Common Uses | Tabletops, cabinet doors, flat panels. | Beams, countertops, flooring, heavy-duty furniture. |

| Cost | Lower cost, easier manufacturing process. | Higher cost due to complexity and thickness. |

Introduction to Edge-Glued and Face-Glued Panels

Edge-glued panels are constructed by bonding narrow wood strips along their edges, creating a wider board primarily used for furniture and tabletop surfaces due to their stability and aesthetic appeal. Face-glued panels consist of multiple layers bonded over their broad faces, often forming plywood or laminated boards known for enhanced structural strength and dimensional stability. Understanding these bonding techniques helps in selecting the appropriate panel type for specific woodworking or construction applications.

Understanding Edge-Glued Panels

Edge-glued panels consist of narrow wood strips joined along their edges using strong adhesive to create wider boards that maintain structural integrity and minimize warping. These panels offer enhanced dimensional stability and are commonly used in furniture making and cabinetry due to their strength and consistent grain appearance. Properly manufactured edge-glued panels provide superior durability compared to face-glued alternatives, which simply bond larger faces rather than narrow edges.

What are Face-Glued Panels?

Face-glued panels consist of multiple lumber boards glued together side by side along their wide faces to form a larger, flat panel, commonly used in furniture and cabinetry. These panels provide a smooth, continuous surface ideal for aesthetic applications while maintaining structural stability in the plane of the panel. Understanding the difference helps you choose the right panel type for projects requiring either surface uniformity or edge strength.

Manufacturing Processes Explained

Edge-glued panels are created by joining narrow wood strips along their edges using waterproof adhesive and clamps, producing a wider board that maintains grain continuity for enhanced strength and stability. Face-glued panels involve bonding larger wood sheets or veneers face-to-face with adhesive under pressure, resulting in laminated surfaces ideal for decorative applications and structural layering. Both manufacturing methods rely on precise adhesive application and controlled curing to ensure durability while serving different functional and aesthetic purposes in woodworking.

Key Differences Between Edge-Glued and Face-Glued Panels

Edge-glued panels are made by joining narrow wood strips glued along their edges to create wider boards, offering increased strength and reduced warping ideal for tabletops and furniture. Face-glued panels consist of multiple plywood or veneer sheets glued face-to-face, resulting in thicker panels with stability suited for cabinetry and structural uses. Understanding these key differences helps you select the right panel type based on project requirements for durability and appearance.

Structural Strength and Durability Comparison

Edge-glued panels feature narrow strips bonded along their edges, resulting in enhanced dimensional stability and resistance to warping, making them ideal for load-bearing applications. Face-glued panels, created by bonding entire surface areas, generally offer less structural strength and can be prone to delamination under stress. The continuity of grain orientation in edge-glued panels contributes significantly to their superior durability compared to the broader adhesive surfaces in face-glued panels.

Aesthetic and Visual Considerations

Edge-glued panels feature visible seams between narrow wood strips that create a distinct, linear pattern enhancing rustic or traditional aesthetics. Face-glued panels consist of wider boards glued flat without noticeable lines, offering a smoother, more uniform surface ideal for modern, seamless designs. Your choice depends on whether you prefer the textured, handcrafted look of edge-gluing or the clean, consistent appearance of face-glued panels.

Common Applications in Woodworking

Edge-glued panels are commonly used for tabletops, cabinet doors, and shelving due to their strength and ability to create wide boards from narrow strips of wood. Face-glued panels are ideal for decorative surfaces and laminates where a smooth, continuous veneer is needed, often seen in furniture design and wall paneling. Your choice depends on whether you prioritize structural integrity or aesthetic surface quality in your woodworking project.

Cost Comparison and Material Efficiency

Edge-glued panels typically offer better cost efficiency due to reduced glue usage and simpler fabrication processes, making them ideal for budget-conscious projects. Face-glued panels, while often providing enhanced surface strength and appearance, tend to be more expensive because of increased adhesive requirements and labor intensity. Your choice between the two should consider the balance between upfront material costs and the desired durability or finish quality of the final product.

Choosing the Right Panel for Your Project

Edge-glued panels are constructed by joining narrow strips of wood side-by-side, offering enhanced stability and reduced warping, making them ideal for furniture and cabinetry requiring strength and durability. Face-glued panels, formed by bonding entire wood sheets, provide a smooth, continuous surface suitable for decorative applications where visual uniformity is essential. Selecting the right panel depends on the specific project requirements such as load-bearing capacity, aesthetic demands, and environmental exposure to ensure longevity and performance.

Edge-glued vs face-glued panels Infographic

libmatt.com

libmatt.com