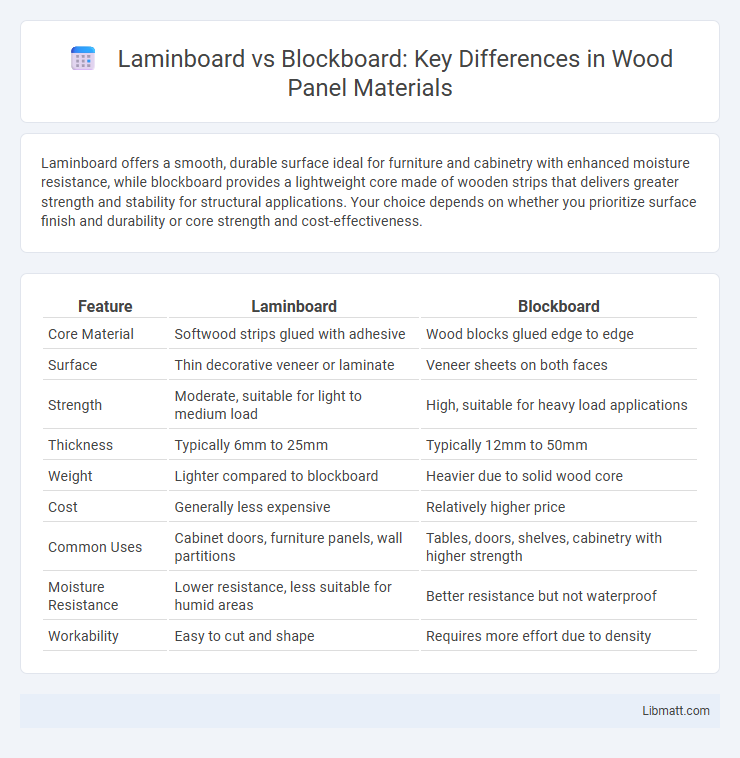

Laminboard offers a smooth, durable surface ideal for furniture and cabinetry with enhanced moisture resistance, while blockboard provides a lightweight core made of wooden strips that delivers greater strength and stability for structural applications. Your choice depends on whether you prioritize surface finish and durability or core strength and cost-effectiveness.

Table of Comparison

| Feature | Laminboard | Blockboard |

|---|---|---|

| Core Material | Softwood strips glued with adhesive | Wood blocks glued edge to edge |

| Surface | Thin decorative veneer or laminate | Veneer sheets on both faces |

| Strength | Moderate, suitable for light to medium load | High, suitable for heavy load applications |

| Thickness | Typically 6mm to 25mm | Typically 12mm to 50mm |

| Weight | Lighter compared to blockboard | Heavier due to solid wood core |

| Cost | Generally less expensive | Relatively higher price |

| Common Uses | Cabinet doors, furniture panels, wall partitions | Tables, doors, shelves, cabinetry with higher strength |

| Moisture Resistance | Lower resistance, less suitable for humid areas | Better resistance but not waterproof |

| Workability | Easy to cut and shape | Requires more effort due to density |

Introduction to Laminboard and Blockboard

Laminboard consists of multiple layers of adhesive-coated wood veneers laminated under heat and pressure, offering a smooth, durable surface ideal for furniture and cabinetry. Blockboard features a core of wooden strips glued together and sandwiched between plywood or veneers, providing strength and resistance to warping for structural applications. Your choice between laminboard and blockboard depends on the desired combination of surface finish, weight, and load-bearing capacity.

What is Laminboard?

Laminboard is a type of engineered wood product consisting of thin wood veneers glued together with a decorative laminate surface, offering durability and aesthetic appeal. It is designed to provide a smooth, moisture-resistant finish ideal for furniture, cabinetry, and interior paneling. Your choice of laminboard ensures enhanced surface protection while maintaining the strength typical of plywood-based boards.

What is Blockboard?

Blockboard is a type of engineered wood made by gluing strips of softwood core between two outer layers of hardwood veneer, offering improved strength and stability compared to plywood. It is commonly used in furniture, doors, and interior paneling, providing a durable and lightweight solution. Your choice of blockboard ensures a cost-effective material with excellent resistance to warping and bending.

Composition and Structure Comparison

Laminboard consists of multiple thin layers of wood veneer glued together with a decorative laminate surface, providing a smooth and durable finish ideal for furniture and cabinetry. Blockboard features a core made of solid wooden strips sandwiched between two plywood veneers, offering superior strength and stability for doors and paneling. Understanding these structural differences helps you choose the right material based on load-bearing capacity and aesthetic requirements.

Strength and Durability Differences

Laminboard offers superior surface hardness and resistance to scratches due to its laminated veneer layer, making it ideal for decorative and light-use applications. Blockboard features a solid core of wooden strips, providing greater tensile strength and structural stability, which excels in heavy-duty and load-bearing furniture. While blockboard resists warping and bending under pressure, laminboard prioritizes aesthetic durability with a smoother finish.

Weight and Workability

Laminboard is generally lighter than blockboard due to its composition of thin veneers bonded over a lightweight core, which enhances ease of handling and reduces transportation costs. Blockboard, constructed with a solid core of softwood strips, offers greater rigidity but results in heavier panels that may be more challenging to maneuver during installation. The superior workability of laminboard allows for smoother cutting and shaping, while blockboard's denser core provides better screw-holding capacity and durability in applications requiring structural strength.

Surface Finish and Aesthetics

Laminboard features a smooth, durable surface achieved by fusing decorative laminate sheets, offering a wide range of colors, patterns, and textures ideal for modern interior designs. Blockboard has a natural wood veneer finish that highlights wood grain, providing an authentic and warm aesthetic preferred in traditional or classic settings. Laminboard's consistent surface is resistant to scratches and stains, while blockboard's surface may require regular maintenance to preserve its appearance.

Common Applications and Uses

Laminboard is widely used for cabinetry, furniture surfaces, and decorative wall panels due to its smooth finish and resistance to moisture. Blockboard is preferred in door cores, table tops, and shelving because of its strength and durability provided by solid wooden strips at its core. Both materials serve key roles in interior construction but differ in structural applications based on their composition.

Cost Comparison

Laminboard typically offers a more budget-friendly option compared to blockboard due to its thinner core and use of laminated veneers, resulting in lower material costs. Blockboard, featuring a solid wooden strip core, tends to be more expensive but provides greater strength and durability, making it suitable for heavy-duty furniture. Understanding your project's structural needs will help you decide which board's cost aligns best with your long-term investment.

Which is Better: Laminboard or Blockboard?

Laminboard offers a durable surface with enhanced resistance to moisture and scratches, making it ideal for furniture that requires a polished, low-maintenance finish. Blockboard provides superior strength and stability due to its solid wooden core, perfect for heavy-duty applications like doors and shelves. Your choice between laminboard and blockboard should depend on the specific needs of your project, balancing aesthetics and structural support.

Laminboard vs blockboard Infographic

libmatt.com

libmatt.com