Pre-finished wood offers a smooth, durable surface with a factory-applied finish that saves time and protects against moisture and scratches. Unfinished wood allows you to customize the stain and finish to match your style but requires additional effort for sanding, staining, and sealing to ensure long-lasting durability.

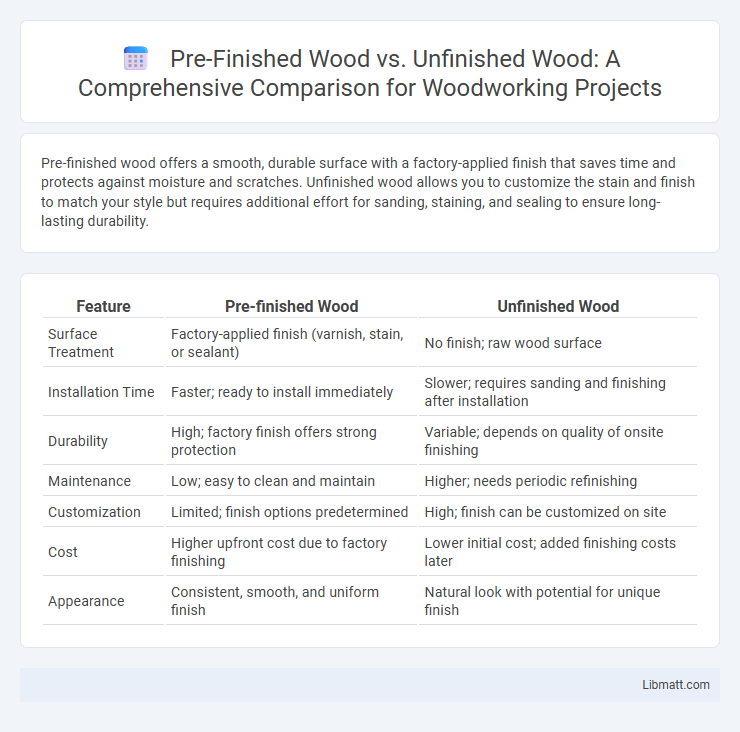

Table of Comparison

| Feature | Pre-finished Wood | Unfinished Wood |

|---|---|---|

| Surface Treatment | Factory-applied finish (varnish, stain, or sealant) | No finish; raw wood surface |

| Installation Time | Faster; ready to install immediately | Slower; requires sanding and finishing after installation |

| Durability | High; factory finish offers strong protection | Variable; depends on quality of onsite finishing |

| Maintenance | Low; easy to clean and maintain | Higher; needs periodic refinishing |

| Customization | Limited; finish options predetermined | High; finish can be customized on site |

| Cost | Higher upfront cost due to factory finishing | Lower initial cost; added finishing costs later |

| Appearance | Consistent, smooth, and uniform finish | Natural look with potential for unique finish |

Introduction to Pre-finished and Unfinished Wood

Pre-finished wood is factory-coated with stains, sealants, and protective finishes, ensuring a consistent appearance and immediate usability for flooring, cabinetry, and furniture. Unfinished wood is raw, without any coatings, allowing complete customization through sanding, staining, and finishing on-site to match specific design preferences. Understanding the differences in preparation, durability, and installation helps homeowners and professionals select the optimal wood type for their projects.

What Is Pre-finished Wood?

Pre-finished wood refers to wood flooring or panels that have been sanded, stained, and sealed at the factory before installation, offering a consistent finish and quicker setup time. This type of wood undergoes multiple coats of protective coating, ensuring durability and resistance to wear right out of the box. Choosing pre-finished wood can save your project time and reduce the need for additional finishing on-site.

What Is Unfinished Wood?

Unfinished wood refers to lumber that has not been treated, stained, or sealed after milling, leaving its natural surface exposed. This type of wood allows for custom finishing options, providing flexibility in choice of stain, paint, or protective coatings tailored to specific project needs. It is commonly used in woodworking, cabinetry, and flooring where a personalized aesthetic or finish is desired.

Key Differences Between Pre-finished and Unfinished Wood

Pre-finished wood comes with a factory-applied coating that ensures a consistent finish, enhanced durability, and immediate usability, whereas unfinished wood requires sanding, staining, and sealing on-site for a customized look. Pre-finished wood offers faster installation and reduced labor costs, while unfinished wood allows for greater control over color and finish but demands more time and skill. Choosing between pre-finished and unfinished wood depends on your project timeline, budget, and desired aesthetic outcome.

Installation Process Comparison

Pre-finished wood flooring offers a quicker and cleaner installation process since it arrives sanded, stained, and sealed, eliminating the need for onsite finishing. Unfinished wood requires additional steps like sanding, staining, and sealing after installation, which prolongs the project timeline and demands more expertise. Your choice affects labor costs and project duration, with pre-finished wood providing a more efficient and less disruptive installation experience.

Durability and Maintenance Considerations

Pre-finished wood offers enhanced durability due to factory-applied coatings that provide superior resistance to scratches, moisture, and UV damage, reducing the need for frequent maintenance. Unfinished wood requires on-site finishing, which can be time-consuming and may result in uneven protection, making it more susceptible to wear and environmental damage over time. Regular sealing and refinishing are essential for maintaining the longevity of unfinished wood, while pre-finished wood typically demands less upkeep.

Design and Customization Options

Pre-finished wood offers a limited range of design and customization options since it comes with factory-applied stains and finishes, ensuring consistency but restricting personalization. Unfinished wood provides greater flexibility for custom colors, stains, and finishes, allowing homeowners to tailor the appearance to specific design aesthetics and project requirements. Choosing unfinished wood is ideal for unique or intricate applications where precise control over texture, color, and finish is essential.

Cost Differences: Pre-finished vs Unfinished Wood

Pre-finished wood typically costs more upfront due to factory-applied finishes that ensure durability and a polished look, reducing the need for additional labor and materials on-site. Unfinished wood is generally less expensive initially but requires extra expenses for sanding, staining, sealing, and labor, which can increase the total project cost. Choosing between pre-finished and unfinished wood depends on budget considerations, desired finish quality, and installation timeline.

Pros and Cons of Pre-finished Wood

Pre-finished wood offers the advantage of reduced installation time and immediate usability since it arrives sanded, stained, and sealed, minimizing on-site labor and mess. However, its surface may show damage more easily and repairs can be challenging due to factory-applied finishes. While pre-finished wood ensures consistent quality and color, it limits customization options compared to unfinished wood that allows for personalized staining and finishing choices.

Pros and Cons of Unfinished Wood

Unfinished wood offers superior customization, allowing you to choose your preferred stain, finish, and level of protection, ensuring a tailored look that matches your design vision perfectly. It tends to be more cost-effective upfront and allows for easier repairs or refinishing over time, as no factory-applied coatings need to be removed. However, unfinished wood requires more time and effort to sand, stain, and seal properly, and it may be more vulnerable to damage or moisture before finishing compared to pre-finished options.

Pre-finished wood vs unfinished wood Infographic

libmatt.com

libmatt.com