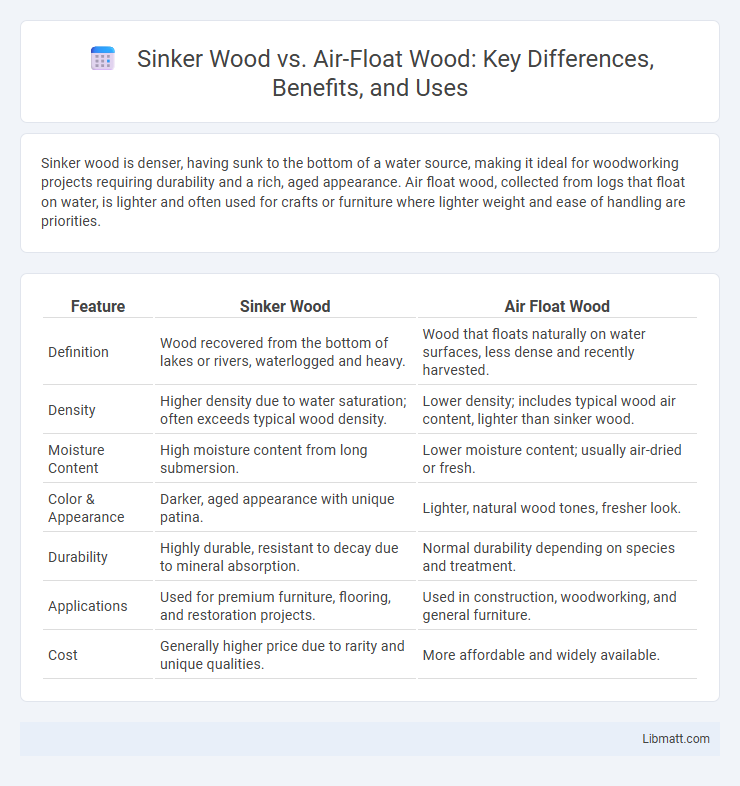

Sinker wood is denser, having sunk to the bottom of a water source, making it ideal for woodworking projects requiring durability and a rich, aged appearance. Air float wood, collected from logs that float on water, is lighter and often used for crafts or furniture where lighter weight and ease of handling are priorities.

Table of Comparison

| Feature | Sinker Wood | Air Float Wood |

|---|---|---|

| Definition | Wood recovered from the bottom of lakes or rivers, waterlogged and heavy. | Wood that floats naturally on water surfaces, less dense and recently harvested. |

| Density | Higher density due to water saturation; often exceeds typical wood density. | Lower density; includes typical wood air content, lighter than sinker wood. |

| Moisture Content | High moisture content from long submersion. | Lower moisture content; usually air-dried or fresh. |

| Color & Appearance | Darker, aged appearance with unique patina. | Lighter, natural wood tones, fresher look. |

| Durability | Highly durable, resistant to decay due to mineral absorption. | Normal durability depending on species and treatment. |

| Applications | Used for premium furniture, flooring, and restoration projects. | Used in construction, woodworking, and general furniture. |

| Cost | Generally higher price due to rarity and unique qualities. | More affordable and widely available. |

Introduction to Sinker Wood and Air Float Wood

Sinker wood, distinguished by its high density and water absorption, is wood that has sunk in water for decades, often salvaged from lake beds or river bottoms. Air float wood, in contrast, is timber that originally floated on water before being harvested, generally exhibiting lower density and lighter weight. These differences impact their durability, applications, and value in woodworking and furniture making.

What is Sinker Wood?

Sinker wood is timber that has naturally sunk and been preserved underwater for extended periods, often decades or even centuries, resulting in a denser, more durable wood due to water absorption. Compared to air float wood, which has been dried and floated in water, sinker wood typically exhibits enhanced stability, resistance to decay, and unique aesthetic qualities like rich color and tighter grain patterns. If you're seeking wood with exceptional longevity and strength for specialized applications, sinker wood may offer significant advantages.

What is Air Float Wood?

Air float wood refers to timber that naturally floats on water due to its lower density and higher buoyancy compared to sinker wood, which sinks because of its increased density from prolonged submersion. This distinction occurs as air float wood typically contains more air pockets and less waterlogged material, affecting its properties and suitability for different woodworking or construction applications. You can identify air float wood by its lighter weight and buoyant behavior, important factors for specific uses in boat building and marine construction.

Sourcing and Availability

Sinker wood originates from trees submerged in water for extended periods, often recovered from riverbeds or lakes, making its sourcing limited and dependent on specific geographic areas with historic logging activity. Air float wood, by contrast, is harvested from timber that has floated and dried naturally after falling into water, resulting in more readily available supplies from conventional logging regions. The rarity of sinker wood contributes to higher market value and scarcity, whereas air float wood remains more accessible and consistent due to regular forestry operations.

Physical and Structural Differences

Sinker wood is denser and heavier than air float wood, resulting from its prolonged submersion in water, which increases its moisture content and mineral absorption. Air float wood is lighter and less dense because it originates from the upper sections of a log that float during water transport, retaining more air and fewer minerals. Structurally, sinker wood tends to have tighter growth rings and a more uniform texture, while air float wood often displays wider growth rings and less compact fiber arrangement.

Color, Grain, and Aesthetic Appeal

Sinker wood typically displays deeper, richer hues ranging from dark browns to reddish tones, offering a unique aesthetic appeal due to its dense and often intricate grain patterns formed under waterlogged conditions. Air float wood, cured more traditionally, tends to be lighter in color with more uniform grain, providing a cleaner and more consistent look preferred for fine woodworking. The natural variations in sinker wood's color and grain make it highly sought after for rustic or artistic projects, while air float wood favors sleek, modern designs.

Durability and Stability

Sinker wood, submerged for decades in oxygen-poor environments, exhibits enhanced durability due to reduced decay and fungal growth, making it highly resistant to rot and pests. Its dense, waterlogged structure also contributes to excellent dimensional stability, minimizing warping and shrinking over time. In contrast, air float wood, dried naturally in open air, tends to have lower durability and is more susceptible to environmental changes, which can cause greater movement and decreased longevity.

Common Uses and Applications

Sinker wood, often valued in fine woodworking and boat building, is prized for its density and resistance to water, making it ideal for outdoor furniture and flooring applications. Air float wood, which dries naturally in open air, is frequently used in construction, cabinetry, and general carpentry due to its stable moisture content and cost-effectiveness. Understanding these characteristics helps you select the right wood type for durable, high-quality projects.

Environmental Impact and Sustainability

Sinker wood, typically sourced from submerged ancient forests, represents a non-renewable resource due to its limited and finite underwater deposits, raising concerns about environmental depletion and habitat disturbance during extraction. In contrast, air float wood is harvested from living trees above ground, allowing for sustainable forestry practices such as selective logging and replanting, which support ecosystem balance and carbon sequestration. Choosing air float wood over sinker wood significantly reduces environmental impact by promoting renewable resource management and minimizing disruption to aquatic ecosystems.

Sinker Wood vs Air Float Wood: Key Takeaways

Sinker wood, typically found in waterlogged environments, is denser and more durable due to its prolonged exposure to saturated conditions, making it ideal for heavy construction and outdoor projects. Air float wood, which grows in well-drained soils, has a lighter density and more uniform grain, often preferred for furniture and interior applications requiring finer finishes. Understanding the distinct characteristics of sinker wood versus air float wood is crucial for selecting the appropriate material based on strength, moisture content, and long-term performance.

Sinker wood vs Air float wood Infographic

libmatt.com

libmatt.com