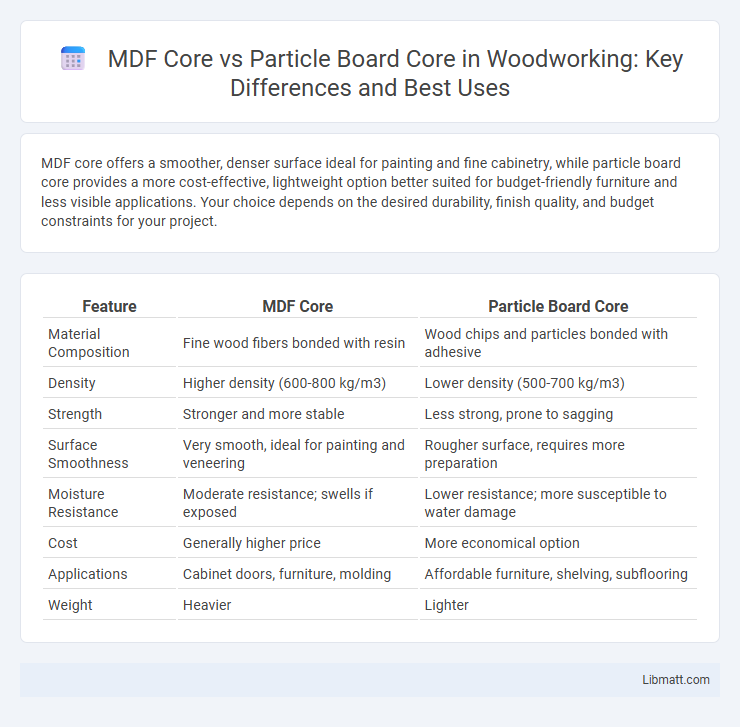

MDF core offers a smoother, denser surface ideal for painting and fine cabinetry, while particle board core provides a more cost-effective, lightweight option better suited for budget-friendly furniture and less visible applications. Your choice depends on the desired durability, finish quality, and budget constraints for your project.

Table of Comparison

| Feature | MDF Core | Particle Board Core |

|---|---|---|

| Material Composition | Fine wood fibers bonded with resin | Wood chips and particles bonded with adhesive |

| Density | Higher density (600-800 kg/m3) | Lower density (500-700 kg/m3) |

| Strength | Stronger and more stable | Less strong, prone to sagging |

| Surface Smoothness | Very smooth, ideal for painting and veneering | Rougher surface, requires more preparation |

| Moisture Resistance | Moderate resistance; swells if exposed | Lower resistance; more susceptible to water damage |

| Cost | Generally higher price | More economical option |

| Applications | Cabinet doors, furniture, molding | Affordable furniture, shelving, subflooring |

| Weight | Heavier | Lighter |

Introduction to MDF Core and Particle Board Core

MDF core consists of finely ground wood fibers bonded with resin under high heat and pressure, providing a smooth, uniform structure ideal for painting and veneering. Particle board core is made from larger wood chips and particles bonded with adhesive, offering a cost-effective but less dense and durable option compared to MDF. Both cores serve as substrates for engineered wood products, with MDF core preferred for precision and finish quality whereas particle board core is valued for budget-friendly applications.

Composition and Manufacturing Process

MDF core is made from fine wood fibers bonded together with resin under high pressure and heat, resulting in a smooth, dense, and uniform material ideal for detailed machining. Particle board core consists of larger wood chips and particles mixed with adhesive, pressed into sheets with lower density and less smoothness compared to MDF. Understanding these differences in composition and manufacturing helps you select the right core for applications requiring strength, finish quality, or cost-efficiency.

Physical Properties Comparison

MDF core offers a smoother, denser texture with superior uniformity, resulting in enhanced strength and stability compared to particle board core, which is more porous and prone to chipping. Your choice impacts durability, as MDF core exhibits better resistance to warping and provides a finer finish ideal for detailed cabinetry or furniture. Particle board core, while more affordable, typically has lower moisture resistance and compressive strength, making it less suitable for high-stress or humid environments.

Strength and Durability

MDF core offers higher density and uniformity, resulting in superior strength and durability compared to particle board core, which is more prone to chipping and warping under stress. Its fine fibers make MDF core resistant to splitting and provide a smoother surface finish, ideal for cabinetry and furniture that require longevity. Choosing MDF core for your projects ensures greater structural integrity and a longer lifespan than particle board core.

Surface Smoothness and Finish

MDF core offers a superior surface smoothness compared to particle board core, making it ideal for high-quality finishes and detailed painting. Its uniform density allows for a consistent and smooth finish without the need for excessive sanding or fillers. If your project demands a flawless surface for veneers or laminates, MDF core is the preferred choice to achieve professional results.

Weight and Density Differences

MDF core typically exhibits higher density values, ranging from 600 to 800 kg/m3, making it significantly denser and heavier than particle board core, which generally falls between 400 and 700 kg/m3. The increased density of MDF results from its fine wood fibers being tightly compressed, enhancing strength and weight compared to the coarser, flake-based composition of particle board. These weight and density differences influence their suitability for applications requiring durability, with MDF cores favored for heavier load-bearing furniture and particle board cores preferred for lightweight, cost-effective uses.

Cost Considerations

MDF core panels generally cost more than particle board core due to higher density and superior performance in strength and smoothness, making them ideal for fine finishes and cabinetry. Particle board core offers a budget-friendly alternative with adequate durability for basic furniture and shelving but may require more frequent replacements. Cost-efficiency depends on project requirements, balancing MDF's premium pricing against its longer lifespan and better aesthetics compared to the economical particle board core.

Applications and Common Uses

MDF core is widely used in high-end furniture, cabinetry, and decorative applications due to its smooth surface and uniform density, ideal for painting and veneering. Particle board core is commonly found in affordable furniture, shelving, and underlayment, favored for its cost-effectiveness and adequate structural support despite lower moisture resistance. Both materials serve as substrates in laminate flooring and kitchen countertops, with MDF preferred for precision machining and particle board chosen for budget-friendly construction.

Environmental Impact and Sustainability

MDF core typically has a higher density and requires more energy and chemicals in its production compared to particle board core, which is made from larger wood chips and resins. Particle board core often uses more recycled wood materials, making it a more sustainable choice with a lower carbon footprint. When selecting materials for your project, considering the environmental impact of MDF versus particle board core helps support eco-friendly decisions.

How to Choose Between MDF Core and Particle Board Core

Choosing between MDF core and particle board core depends on the specific requirements of your project, such as durability, weight, and budget. MDF core offers a denser, smoother surface ideal for detailed painting and machining, while particle board core is lighter and more cost-effective but less moisture-resistant and durable. Evaluate the intended use, environmental exposure, and finish quality to determine the best core material for furniture, cabinetry, or doors.

MDF core vs particle board core Infographic

libmatt.com

libmatt.com