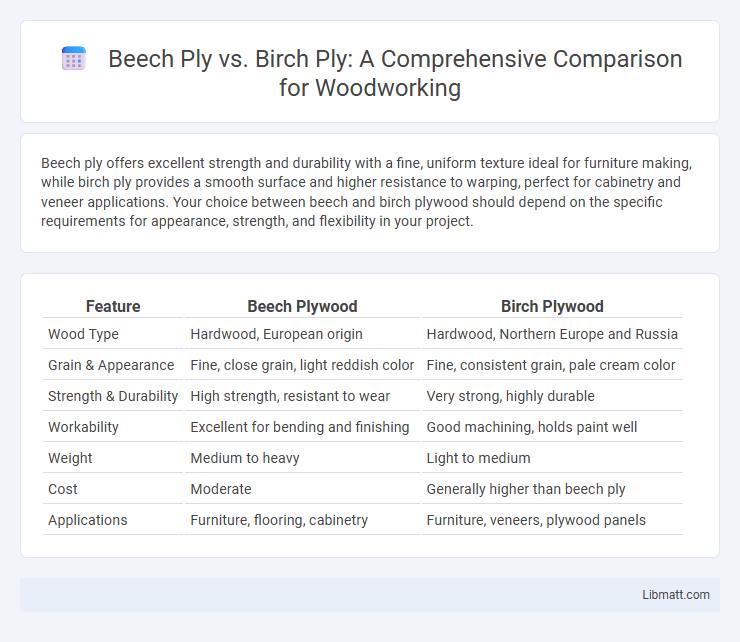

Beech ply offers excellent strength and durability with a fine, uniform texture ideal for furniture making, while birch ply provides a smooth surface and higher resistance to warping, perfect for cabinetry and veneer applications. Your choice between beech and birch plywood should depend on the specific requirements for appearance, strength, and flexibility in your project.

Table of Comparison

| Feature | Beech Plywood | Birch Plywood |

|---|---|---|

| Wood Type | Hardwood, European origin | Hardwood, Northern Europe and Russia |

| Grain & Appearance | Fine, close grain, light reddish color | Fine, consistent grain, pale cream color |

| Strength & Durability | High strength, resistant to wear | Very strong, highly durable |

| Workability | Excellent for bending and finishing | Good machining, holds paint well |

| Weight | Medium to heavy | Light to medium |

| Cost | Moderate | Generally higher than beech ply |

| Applications | Furniture, flooring, cabinetry | Furniture, veneers, plywood panels |

Introduction to Beech Ply and Birch Ply

Beech ply features dense, fine-grained wood known for high durability and smooth finishing, making it ideal for furniture and cabinetry. Birch ply offers a light, pale color with strong structural integrity, commonly used in plywood applications requiring strength and aesthetic appeal. Understanding the specific properties of beech and birch ply helps you select the best material for your woodworking or construction projects.

Origins and Types of Beech and Birch Plywood

Beech plywood originates from the European beech tree (Fagus sylvatica), prized for its fine grain and durability, often used in furniture and cabinetry. Birch plywood comes from various birch species, notably Betula pendula and Betula papyrifera, valued for its light color, smooth finish, and strength in construction and interior projects. Understanding the distinct origins and types of beech and birch plywood helps you select the best material suited for specific applications.

Physical and Mechanical Properties Comparison

Beech ply exhibits higher density, typically around 700-750 kg/m3, offering greater hardness and resistance to wear compared to birch ply, which has a density of approximately 600-650 kg/m3. Mechanically, beech plywood demonstrates superior bending strength and stiffness, making it ideal for applications requiring load-bearing capabilities, while birch plywood provides excellent flexibility and shock resistance. Both types measure similar tensile strength levels, but beech ply's enhanced durability makes it more suitable for heavy-duty furniture and flooring solutions.

Grain Pattern and Aesthetic Appeal

Beech ply features a tight, uniform grain pattern with a smooth texture, providing a consistent, light color that enhances modern and minimalist designs. Birch ply displays a more pronounced, fine grain with subtle variations in tone, resulting in a warm and natural aesthetic favored in high-end furniture and cabinetry. Both offer excellent aesthetic appeal, but beech ply's sleek look contrasts with birch ply's distinctive, attractive grain for versatile interior applications.

Workability and Machining Differences

Beech ply offers superior workability with its fine, even texture, making it easier to cut, shape, and sand compared to birch ply, which tends to be harder and denser. Birch ply features tightly packed grains that can require sharper tools and slower feed rates to avoid tear-out during machining. Choosing between these materials depends on your project's precision needs and the type of tools available for efficient fabrication.

Durability and Strength: Beech vs Birch

Beech plywood offers exceptional durability due to its dense grain structure and resistance to wear, making it ideal for heavy-use furniture and flooring. Birch plywood is renowned for its high strength-to-weight ratio and uniform grain, providing excellent structural stability for cabinetry and plywood panels. Both woods are strong, but beech ply is typically harder and more impact-resistant, while birch ply excels in bending strength and resistance to splitting.

Cost Analysis and Market Availability

Beech plywood generally costs more than birch plywood due to its higher density and durability, making it a preferred choice for premium furniture and flooring. Birch plywood is widely available in most markets, offering a budget-friendly and versatile option suitable for cabinetry and general construction purposes. When choosing between the two, your decision should factor in both the cost premium of beech ply and the ease of sourcing birch ply for your specific project needs.

Best Use Cases for Beech Ply

Beech ply offers exceptional strength and durability, making it ideal for furniture manufacturing, cabinetry, and flooring applications where a smooth surface finish and resistance to wear are essential. Its fine grain and consistent texture also suit interior joinery and decorative veneers, providing both aesthetic appeal and functional resilience. Compared to birch ply, beech ply performs better under heavy loads and in environments requiring high stability and impact resistance.

Ideal Applications for Birch Ply

Birch plywood is ideal for applications requiring high strength, durability, and a smooth surface finish, such as cabinetry, furniture-making, and interior paneling. Its fine grain and consistent layers allow for excellent machining and finishing, making it suitable for decorative veneers and detailed woodworking. You will find birch ply especially favored in projects demanding superior structural integrity and aesthetic appeal.

Choosing the Right Ply for Your Project

Beech ply offers superior hardness and a fine, uniform texture ideal for furniture and flooring that demands durability and a smooth finish. Birch ply provides excellent strength-to-weight ratio and a pale, consistent appearance, making it suitable for lightweight constructions and cabinetry. Assess your project's requirements for strength, aesthetics, and weight to determine whether beech ply or birch ply aligns best with your goals.

Beech ply vs birch ply Infographic

libmatt.com

libmatt.com