Chipboard offers a smooth surface ideal for furniture and interior applications, while OSB provides superior strength and moisture resistance, making it suitable for structural uses like flooring and wall sheathing. Choosing between chipboard and OSB depends on your project's specific requirements for durability, appearance, and exposure to elements.

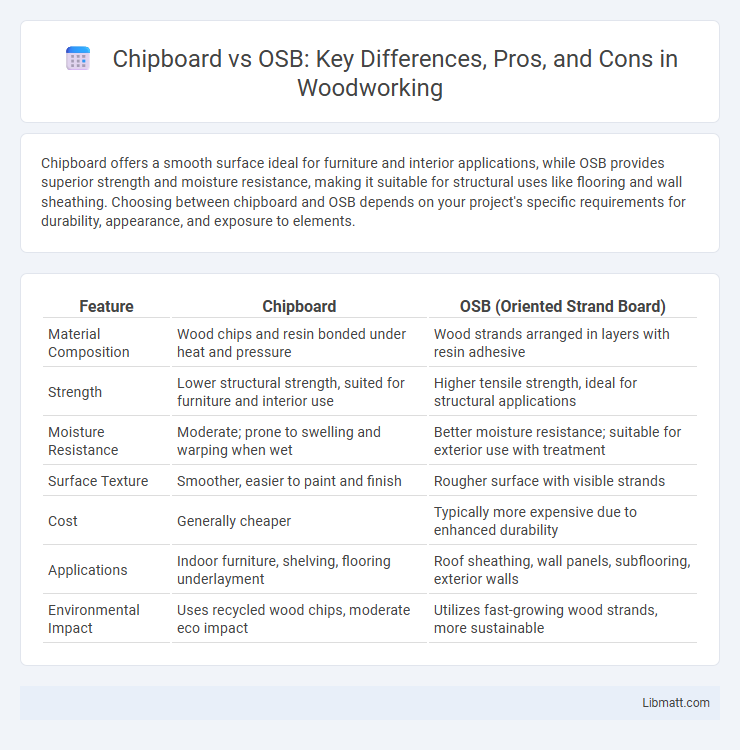

Table of Comparison

| Feature | Chipboard | OSB (Oriented Strand Board) |

|---|---|---|

| Material Composition | Wood chips and resin bonded under heat and pressure | Wood strands arranged in layers with resin adhesive |

| Strength | Lower structural strength, suited for furniture and interior use | Higher tensile strength, ideal for structural applications |

| Moisture Resistance | Moderate; prone to swelling and warping when wet | Better moisture resistance; suitable for exterior use with treatment |

| Surface Texture | Smoother, easier to paint and finish | Rougher surface with visible strands |

| Cost | Generally cheaper | Typically more expensive due to enhanced durability |

| Applications | Indoor furniture, shelving, flooring underlayment | Roof sheathing, wall panels, subflooring, exterior walls |

| Environmental Impact | Uses recycled wood chips, moderate eco impact | Utilizes fast-growing wood strands, more sustainable |

Introduction to Chipboard and OSB

Chipboard, also known as particleboard, consists of wood particles bonded together with resin, offering a smooth, flat surface ideal for furniture and cabinetry. Oriented Strand Board (OSB) is made from compressed wood strands arranged in specific orientations, providing superior strength and durability for structural applications like flooring and wall sheathing. Understanding the distinct composition and uses of chipboard and OSB helps you select the right material for your construction or woodworking project.

What is Chipboard?

Chipboard, also known as particleboard, is an engineered wood product made from wood chips, sawdust, and resin compressed under heat and pressure to form dense panels. It is commonly used in furniture manufacturing, cabinetry, and flooring due to its smooth surface and affordability compared to plywood or OSB (Oriented Strand Board). Your choice between chipboard and OSB will depend on the specific strength, moisture resistance, and appearance requirements of your project.

What is OSB?

OSB (Oriented Strand Board) is an engineered wood panel made by layering strands of wood in specific orientations and bonding them with adhesives under heat and pressure. It offers excellent structural strength and moisture resistance, making it a common choice for subflooring, wall sheathing, and roofing applications. You will find OSB to be more uniform in density and less prone to warping compared to traditional chipboard.

Manufacturing Processes Compared

Chipboard is manufactured by compressing wood chips, sawmill shavings, and resin under high heat and pressure, resulting in a dense and smooth panel ideal for furniture and flooring. OSB (Oriented Strand Board) production involves layering large wood strands in specific orientations, bonded with waterproof adhesives, and pressed to create a strong, moisture-resistant panel commonly used in construction sheathing. The key difference in manufacturing lies in the size and orientation of wood particles, impacting durability, moisture resistance, and structural performance.

Strength and Durability Differences

OSB (Oriented Strand Board) offers superior strength and durability compared to traditional chipboard due to its layered construction of wood strands bonded with adhesives in specific orientations. Chipboard is composed of small wood particles pressed together, making it less dense and more prone to moisture damage and breakage under heavy loads. For your construction or furniture projects requiring robust support and long-term performance, OSB is generally the more reliable choice.

Moisture Resistance: Chipboard vs OSB

OSB (Oriented Strand Board) offers superior moisture resistance compared to chipboard, making it more suitable for areas prone to humidity or occasional water exposure. Chipboard tends to absorb moisture, leading to swelling and reduced structural integrity, whereas OSB's layered strand composition enables better water repellency and durability. This makes OSB the preferred choice for subflooring, roofing, and external sheathing where moisture exposure is a concern.

Common Applications for Chipboard

Chipboard is commonly used in furniture manufacturing, interior fittings, and shelving due to its smooth surface and ease of veneering. It is ideal for decorative applications such as cabinet backing and drawer bottoms, where a finished appearance is important. Chipboard's affordability and lightweight nature make it popular for temporary construction uses and packaging as well.

Common Applications for OSB

OSB (Oriented Strand Board) is widely used in wall sheathing, roofing, and subflooring due to its strength and moisture resistance. Its engineered layers provide excellent structural performance, making it ideal for load-bearing applications in residential and commercial construction. You can rely on OSB for durability in areas exposed to varying weather conditions and heavy usage.

Environmental Impact and Sustainability

Chipboard, made from wood chips and synthetic resin, often utilizes recycled wood waste, contributing to resource efficiency and reducing landfill use, while its formaldehyde emissions vary by product grade. OSB (Oriented Strand Board) is manufactured from fast-growing trees with adhesives designed for durability, offering a renewable and less wasteful alternative to traditional plywood without significant deforestation. Choosing between chipboard and OSB impacts your project's environmental footprint depending on factors like raw material sourcing, formaldehyde content, and end-of-life recyclability.

Cost Comparison and Value for Money

Chipboard typically costs less than OSB, making it an attractive option for budget-conscious projects. However, OSB offers greater strength and durability, providing better long-term value for money in structural applications. Your choice depends on balancing upfront savings with performance requirements.

Chipboard vs OSB Infographic

libmatt.com

libmatt.com