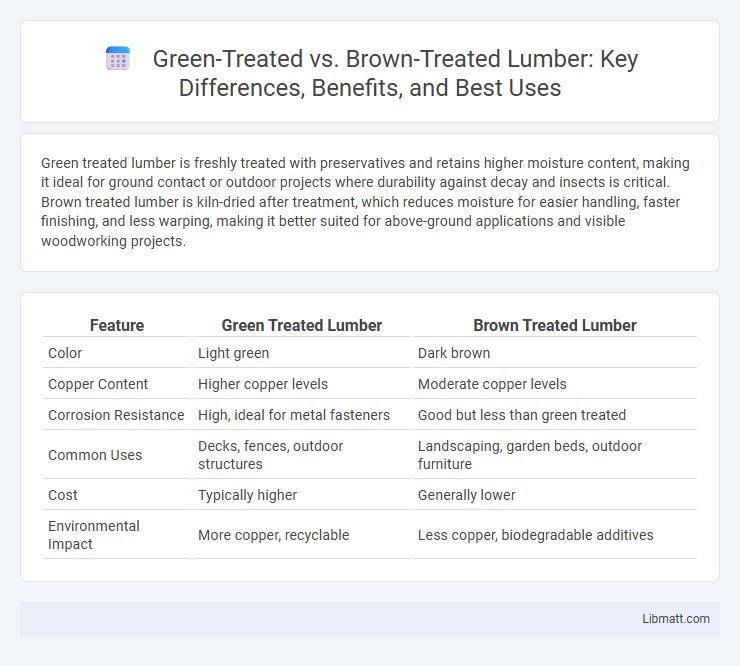

Green treated lumber is freshly treated with preservatives and retains higher moisture content, making it ideal for ground contact or outdoor projects where durability against decay and insects is critical. Brown treated lumber is kiln-dried after treatment, which reduces moisture for easier handling, faster finishing, and less warping, making it better suited for above-ground applications and visible woodworking projects.

Table of Comparison

| Feature | Green Treated Lumber | Brown Treated Lumber |

|---|---|---|

| Color | Light green | Dark brown |

| Copper Content | Higher copper levels | Moderate copper levels |

| Corrosion Resistance | High, ideal for metal fasteners | Good but less than green treated |

| Common Uses | Decks, fences, outdoor structures | Landscaping, garden beds, outdoor furniture |

| Cost | Typically higher | Generally lower |

| Environmental Impact | More copper, recyclable | Less copper, biodegradable additives |

Introduction to Treated Lumber

Treated lumber is essential for outdoor construction due to its resistance to decay, insects, and moisture. Green treated lumber undergoes pressure treatment with water-based preservatives, giving it a greenish tint, while brown treated lumber uses different preservatives or overlay stains to provide a darker appearance without compromising durability. Both types enhance structural longevity, but color choice often depends on aesthetic preferences and project requirements.

What is Green Treated Lumber?

Green treated lumber is wood preserved with a water-based chemical treatment that retains moisture, giving it a greenish hue. This treatment protects the wood from decay, insects, and fungal growth, making it ideal for outdoor construction projects such as decks, fences, and landscaping. Understanding the properties of green treated lumber helps you choose the right material for durability and resistance in moist or exposed environments.

What is Brown Treated Lumber?

Brown treated lumber is wood that has been pressure-treated with copper azole or similar preservatives, giving it a distinctive brown color that blends well with natural landscapes. This type of lumber is designed to resist decay, fungal growth, and insect damage, making it ideal for outdoor projects like decks, fences, and landscaping structures. You can choose brown treated lumber for its aesthetic appeal and durability in environments where protection against moisture and pests is essential.

Key Differences: Green vs Brown Treated Lumber

Green treated lumber is freshly treated with preservatives and retains high moisture content, making it heavier and prone to shrinkage, while brown treated lumber has been dried after treatment, offering greater stability and less warping. Green lumber is typically used for ground contact and outdoor applications requiring immediate pressure treatment, whereas brown lumber is preferred for indoor projects or visible structures requiring a cleaner appearance. Your choice depends on moisture tolerance and aesthetic needs, with brown treated wood providing enhanced dimensional stability.

Chemical Treatments and Safety

Green treated lumber undergoes copper-based chemical treatments, primarily copper azole (CA) or alkaline copper quaternary (ACQ), offering strong resistance against rot and insects while being relatively low in toxicity. Brown treated lumber, often coated with a brown-colored water repellent or a different preservative, provides added protection against moisture but may contain higher levels of copper or other biocides, requiring careful handling. Both types of treated wood necessitate the use of gloves and masks during cutting or sanding to minimize exposure to chemical residues and dust.

Durability and Longevity Comparison

Green treated lumber uses copper-based preservatives that penetrate deeply, providing enhanced resistance to rot, decay, and insect damage, resulting in superior durability and longer lifespan compared to brown treated lumber. Brown treated lumber often uses older, less effective chemicals, making it more susceptible to weathering and reducing its longevity in outdoor applications. For projects requiring maximum durability and extended service life, green treated lumber is the preferred choice due to its advanced preservative technology and proven performance.

Applications: Where to Use Each Type

Green treated lumber is ideal for outdoor projects requiring high moisture resistance, such as decks, fences, and retaining walls, due to its copper-based preservative retaining natural wood flexibility. Brown treated lumber, often processed with a different preservative and colorant, is suited for decorative structures and outdoor furniture where aesthetics are important, blending better with natural surroundings. Choose green treated wood for structural durability in wet environments and brown treated wood for visible, less exposed applications that benefit from a natural look.

Environmental Impact and Sustainability

Green treated lumber uses alkaline copper quat (ACQ) or other water-based preservatives, which are less toxic and more environmentally friendly compared to the older brown treated lumber that often contained arsenic-based chemicals like chromated copper arsenate (CCA). Your choice of green treated lumber supports sustainability by reducing harmful chemical leaching into soil and water, promoting safer disposal and recycling. Brown treated lumber, while durable, poses greater environmental risks throughout its lifecycle due to its toxic components and limited eco-friendly disposal options.

Cost Comparison: Green vs Brown Treated Lumber

Green treated lumber generally costs less than brown treated lumber due to simpler drying processes and lower labor requirements. Brown treated lumber undergoes additional heat treatment, increasing production time and expenses, which is reflected in higher market prices. Contractors often choose green treated wood for budget projects, while brown treated lumber is preferred for applications demanding enhanced durability and aesthetic appeal despite the extra cost.

Conclusion: Choosing the Right Treated Lumber

Green treated lumber offers higher moisture content and longer drying time, making it ideal for projects where dimensional stability is less critical. Brown treated lumber contains less moisture, provides better initial strength, and is preferred for visible or finished wood applications. Assess your project's specific needs for moisture tolerance and appearance to select the right treated lumber for optimal durability and performance.

Green treated vs brown treated lumber Infographic

libmatt.com

libmatt.com