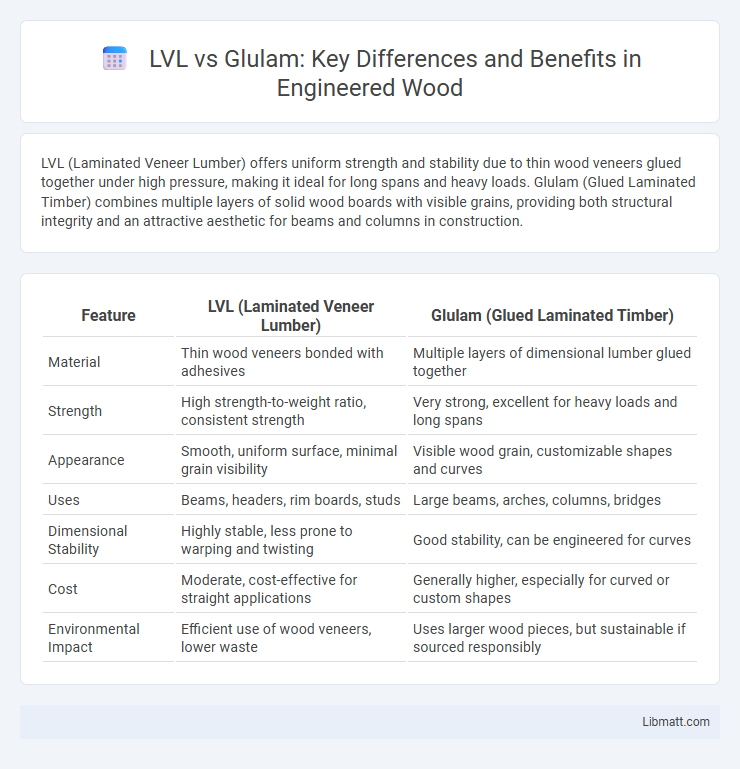

LVL (Laminated Veneer Lumber) offers uniform strength and stability due to thin wood veneers glued together under high pressure, making it ideal for long spans and heavy loads. Glulam (Glued Laminated Timber) combines multiple layers of solid wood boards with visible grains, providing both structural integrity and an attractive aesthetic for beams and columns in construction.

Table of Comparison

| Feature | LVL (Laminated Veneer Lumber) | Glulam (Glued Laminated Timber) |

|---|---|---|

| Material | Thin wood veneers bonded with adhesives | Multiple layers of dimensional lumber glued together |

| Strength | High strength-to-weight ratio, consistent strength | Very strong, excellent for heavy loads and long spans |

| Appearance | Smooth, uniform surface, minimal grain visibility | Visible wood grain, customizable shapes and curves |

| Uses | Beams, headers, rim boards, studs | Large beams, arches, columns, bridges |

| Dimensional Stability | Highly stable, less prone to warping and twisting | Good stability, can be engineered for curves |

| Cost | Moderate, cost-effective for straight applications | Generally higher, especially for curved or custom shapes |

| Environmental Impact | Efficient use of wood veneers, lower waste | Uses larger wood pieces, but sustainable if sourced responsibly |

Introduction to LVL and Glulam

LVL (Laminated Veneer Lumber) consists of thin wood veneers bonded under heat and pressure, offering high strength and consistent performance for structural applications. Glulam (Glue-Laminated Timber) is composed of multiple layers of dimensional lumber glued together, providing versatile, scalable beams ideal for architectural and load-bearing uses. Your choice between LVL and glulam depends on factors like strength requirements, appearance, and project specifications.

What is LVL?

LVL (Laminated Veneer Lumber) is an engineered wood product made by layering thin wood veneers with adhesive, then compressing them under high pressure to form strong, uniform structural beams. It offers superior strength-to-weight ratio, dimensional stability, and resistance to warping compared to traditional solid timber, making it ideal for beams, headers, and columns in construction. LVL is widely used in residential and commercial buildings for load-bearing applications due to its consistent quality and predictable performance.

What is Glulam?

Glulam, or glued laminated timber, is an engineered wood product composed of multiple layers of dimensional lumber bonded together with durable, moisture-resistant adhesives. It offers high strength, dimensional stability, and design flexibility, making it ideal for large structural applications such as beams, arches, and long-span roof systems. Unlike LVL (Laminated Veneer Lumber), which is made from thin wood veneers, glulam utilizes thicker lumber layers, resulting in distinct aesthetic qualities and performance characteristics.

Manufacturing Processes Compared

LVL (Laminated Veneer Lumber) is manufactured by bonding thin wood veneers together under high pressure and heat, creating a strong, stable, and uniform product ideal for structural use. Glulam (Glue-Laminated Timber) involves bonding multiple layers of dimensioned lumber boards with durable adhesives, allowing for customized sizes and curved shapes that emphasize versatility in design. Both processes enhance wood strength and durability, but LVL offers more consistent quality due to the veneer-based lamination, whereas glulam provides greater flexibility in architectural applications.

Structural Strength and Performance

LVL (Laminated Veneer Lumber) offers high tensile and bending strength due to its thin wood veneers bonded under heat and pressure, making it ideal for long-span beams and heavy-load applications. Glulam (Glued Laminated Timber) combines solid wood lamellas, enabling excellent load distribution and resistance to twisting, which enhances its performance in columns and curved structures. Both materials provide superior structural strength compared to traditional lumber, but LVL's uniformity delivers more consistent performance, while glulam allows greater design flexibility.

Applications in Construction

LVL (Laminated Veneer Lumber) and glulam (glued laminated timber) are engineered wood products widely used in construction for structural applications such as beams, headers, and columns. LVL offers high strength and uniformity, making it ideal for long-span floor joists and roof rafters, while glulam's versatility enables curved or custom shapes for architectural features and heavy-load beams. Your choice depends on the specific structural demands and design flexibility required in your construction project.

Durability and Longevity

LVL (Laminated Veneer Lumber) offers high durability due to its dense, engineered structure resisting warping, twisting, and splitting, making it ideal for long-term structural applications. Glulam (Glued Laminated Timber) provides excellent longevity through its multiple layers of solid wood glued under pressure, allowing it to withstand heavy loads and environmental stress with proper maintenance. Your choice between LVL and glulam should consider durability needs, as LVL excels in uniform strength and resistance, while glulam offers superior performance in large-span beams and exposed timber aesthetics.

Cost Considerations

LVL (Laminated Veneer Lumber) typically costs more upfront than glulam due to its manufacturing process and higher strength-to-weight ratio. Glulam offers greater design flexibility and often lower material costs, making it a budget-friendly option for larger structural elements. Your choice should account for long-term performance and installation expenses alongside initial purchase price.

Sustainability and Environmental Impact

LVL (Laminated Veneer Lumber) and glulam (glue-laminated timber) both offer sustainable alternatives to traditional steel and concrete, with glulam generally having a lower environmental impact due to its use of solid wood layers and minimal adhesive. LVL production involves thin wood veneers bonded with resins, which can result in higher energy consumption and potential formaldehyde emissions compared to glulam's thicker, natural wood laminations. Both materials contribute to carbon sequestration, but glulam's simpler manufacturing process often leads to a smaller carbon footprint and enhanced recyclability.

Choosing Between LVL and Glulam

Choosing between LVL (Laminated Veneer Lumber) and glulam depends on your project's structural requirements, aesthetic preferences, and budget. LVL offers high strength and uniformity due to its layered veneer construction, making it ideal for load-bearing beams with consistent performance. Glulam provides design flexibility and a natural wood appearance from its glued laminations, often preferred for visible architectural elements or curved structures.

LVL vs glulam Infographic

libmatt.com

libmatt.com