Rotary cut veneers are produced by peeling the entire log in a continuous sheet, resulting in broad, bold grain patterns ideal for covering large surfaces, while flat cut veneers are sliced tangentially, producing a more refined, cathedral-like grain that enhances the natural beauty of your wood projects. Choosing between rotary cut vs flat cut depends on the desired aesthetic and application, with rotary cuts offering cost-effectiveness and flat cuts providing a classic, detailed appearance.

Table of Comparison

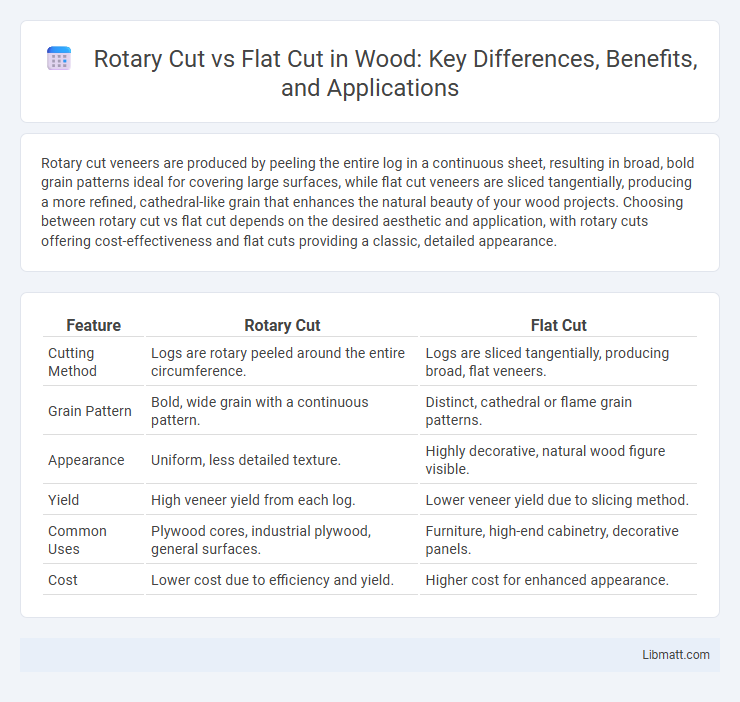

| Feature | Rotary Cut | Flat Cut |

|---|---|---|

| Cutting Method | Logs are rotary peeled around the entire circumference. | Logs are sliced tangentially, producing broad, flat veneers. |

| Grain Pattern | Bold, wide grain with a continuous pattern. | Distinct, cathedral or flame grain patterns. |

| Appearance | Uniform, less detailed texture. | Highly decorative, natural wood figure visible. |

| Yield | High veneer yield from each log. | Lower veneer yield due to slicing method. |

| Common Uses | Plywood cores, industrial plywood, general surfaces. | Furniture, high-end cabinetry, decorative panels. |

| Cost | Lower cost due to efficiency and yield. | Higher cost for enhanced appearance. |

Introduction to Veneer Cutting Techniques

Rotary cut veneer utilizes a log mounted horizontally on a lathe to peel continuous sheets of wood, maximizing yield and creating bold grain patterns ideal for plywood and architectural panels. Flat cut veneer, also known as plain slicing, involves slicing the log tangentially to produce a more varied and natural grain appearance favored in furniture and cabinetry. Each technique optimizes wood utilization and aesthetic qualities, influencing the final veneer's texture, pattern, and structural application.

What is Rotary Cut?

Rotary cut is a woodworking technique where a log is mounted on a lathe and peeled in a continuous sheet, producing wide, veneer sheets with a unique grain pattern. This method reveals the full diameter of the log, creating broad, flowing grain figures often used in plywood and decorative panels. Rotary cut veneers are valued for their efficient use of wood and distinctive, natural appearance.

What is Flat Cut?

Flat cut, also known as plain slicing, is a lumber cutting method where the log is sliced parallel to the growth rings, producing boards with a uniform grain pattern and fewer distortions. This technique results in wider boards with a traditional cathedral grain appearance, often preferred for flooring and paneling due to its aesthetic appeal. Compared to rotary cut, flat cut yields more dimensional stability and visually attractive hardwood surfaces ideal for furniture and decorative uses.

Visual Differences Between Rotary and Flat Cut

Rotary cut veneer displays large, bold grain patterns with a pronounced swirl or loop effect due to the log being sliced in a continuous rotary motion. Flat cut veneer, also known as plain sawn, reveals a more uniform and symmetrical grain pattern characterized by cathedral or flame shapes, offering a classic and traditional appearance. The distinct visual difference lies in rotary cut's dramatic and varied texture versus flat cut's consistent, natural wood grain presentation.

Grain Pattern Characteristics

Rotary cut veneers display a broad, bold grain pattern with large, swirling figures due to the wood being sliced directly from the log, showcasing a more rustic and natural appearance. Flat cut veneers, also known as plain sawn, reveal a cathedral or flame-like grain with symmetrical patterns running parallel to the board edges, highlighting the wood's growth rings. The distinctive grain characteristics of rotary cut emphasize volume and texture, while flat cut emphasizes elegance and uniformity in wood grain presentation.

Manufacturing Processes Explained

Rotary cut veneer involves peeling a log in a continuous, spiral manner, producing wide sheets with a broad grain pattern ideal for covering large surfaces efficiently. Flat cut, also known as plain sawn, slices the log tangentially to the growth rings, resulting in a varied, cathedral grain pattern prized for its aesthetic appeal in furniture and cabinetry. Understanding these manufacturing processes helps you choose the right veneer type for durability, cost, and design preferences.

Typical Applications of Rotary and Flat Cuts

Rotary cut veneers are typically used in applications requiring large sheets with broader grain patterns, such as plywood, laminated panels, and veneer plywood for furniture and cabinetry. Flat cut veneers are preferred for decorative surfaces, fine furniture, architectural millwork, and paneling where a more uniform and aesthetically pleasing grain pattern is desired. Industries focused on interior design and high-end woodworking often select flat cut veneers to maximize visual appeal, while rotary cut is favored for cost-effective, large-scale production.

Advantages and Disadvantages of Each Method

Rotary cut veneer offers the advantage of maximizing wood yield by peeling logs in a continuous spiral, resulting in a broad, consistent grain pattern ideal for plywood and panel products, but it often compromises aesthetic quality due to its less refined appearance. Flat cut veneer provides superior visual appeal with natural grain highlights and symmetrical patterns favored in furniture and cabinetry, though it generates more waste and higher costs because the log is sliced tangentially. Choosing between rotary and flat cut veneers depends on balancing cost-efficiency and material yield against visual quality and grain characteristics for specific woodworking applications.

Cost Comparison: Rotary Cut vs Flat Cut

Rotary cut veneer is generally more cost-effective than flat cut veneer due to its efficient production process that yields larger sheets with less waste. Flat cut veneer involves more labor-intensive slicing techniques, resulting in higher manufacturing costs reflected in the price. Your choice between rotary cut and flat cut should consider budget constraints alongside the desired aesthetic qualities of the wood grain.

Choosing the Right Cut for Your Project

Rotary cut veneer offers a wide, continuous grain pattern ideal for large surfaces like furniture panels, creating a natural and uniform look. Flat cut veneer, also known as plain sliced, showcases a cathedral grain with more variation, perfect for decorative pieces where visual appeal matters most. Understanding how these cuts influence texture and appearance helps you choose the right cut for your project's aesthetic and functional needs.

Rotary cut vs flat cut Infographic

libmatt.com

libmatt.com