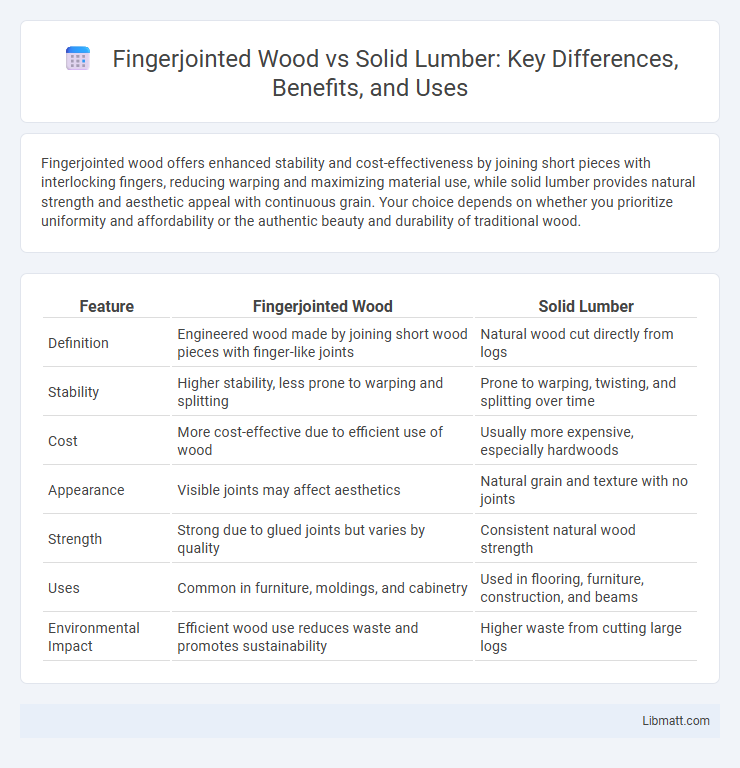

Fingerjointed wood offers enhanced stability and cost-effectiveness by joining short pieces with interlocking fingers, reducing warping and maximizing material use, while solid lumber provides natural strength and aesthetic appeal with continuous grain. Your choice depends on whether you prioritize uniformity and affordability or the authentic beauty and durability of traditional wood.

Table of Comparison

| Feature | Fingerjointed Wood | Solid Lumber |

|---|---|---|

| Definition | Engineered wood made by joining short wood pieces with finger-like joints | Natural wood cut directly from logs |

| Stability | Higher stability, less prone to warping and splitting | Prone to warping, twisting, and splitting over time |

| Cost | More cost-effective due to efficient use of wood | Usually more expensive, especially hardwoods |

| Appearance | Visible joints may affect aesthetics | Natural grain and texture with no joints |

| Strength | Strong due to glued joints but varies by quality | Consistent natural wood strength |

| Uses | Common in furniture, moldings, and cabinetry | Used in flooring, furniture, construction, and beams |

| Environmental Impact | Efficient wood use reduces waste and promotes sustainability | Higher waste from cutting large logs |

Introduction: Understanding Fingerjointed Wood and Solid Lumber

Fingerjointed wood is made by joining short pieces of wood with interlocking fingers glued together, creating long, stable boards resistant to warping and splitting. Solid lumber, cut directly from a single tree, offers natural strength and unique grain patterns but may be more prone to cracking and twisting over time. Understanding these differences helps you choose the best material for your woodworking project in terms of durability, appearance, and cost.

Composition and Manufacturing Processes

Fingerjointed wood consists of short wood pieces joined end-to-end using interlocking finger-like cuts and strong adhesives, creating longer, stable boards with minimal waste. Solid lumber is cut directly from a single log, maintaining natural grain continuity but often displaying variations such as knots and warping. Manufacturing fingerjointed wood involves precise cutting and gluing technology to enhance structural integrity, while solid lumber relies on traditional sawing and drying methods.

Strength and Structural Performance

Fingerjointed wood offers comparable strength and structural performance to solid lumber by joining shorter wood pieces using precise interlocking joints and adhesive, enhancing stability and reducing warping or splitting. Engineering tests show that fingerjointed wood can withstand similar load-bearing stresses and bending forces as solid wood, making it ideal for construction where uniform strength is required. Your choice between fingerjointed and solid lumber should consider consistency, as fingerjointed wood provides reliable, engineered strength with fewer defects.

Appearance and Visual Consistency

Fingerjointed wood offers a uniform appearance with continuous grain patterns created by bonding small wood pieces, reducing natural defects and knots found in solid lumber. Solid lumber exhibits unique, natural grain variations and knots that provide authentic character but may lack the visual consistency found in fingerjointed products. For projects requiring a smooth, consistent look, fingerjointed wood provides a reliable, visually uniform alternative to the varied aesthetics of solid lumber.

Durability and Longevity

Fingerjointed wood offers enhanced stability and resistance to warping compared to solid lumber due to its engineered construction, which joins shorter wood pieces with strong adhesive bonds. While solid lumber boasts natural strength and longevity, fingerjointed wood often surpasses it in durability by minimizing defects like knots and splits. Choosing fingerjointed wood can extend the life of your project by providing consistent performance and reduced risk of damage over time.

Cost Comparison and Budget Considerations

Fingerjointed wood typically costs less than solid lumber due to efficient use of smaller wood pieces and reduced waste during manufacturing. Your budget benefits from the affordability of fingerjointed wood, especially for large projects or where uniformity and stability are essential. Solid lumber, while generally more expensive, offers natural strength and aesthetic appeal but may lead to higher costs and variability in pricing.

Environmental Impact and Sustainability

Fingerjointed wood reduces waste by utilizing smaller wood pieces, making it a more sustainable choice compared to solid lumber, which often requires harvesting larger trees. This engineered wood product promotes efficient use of resources, lowering deforestation rates and minimizing environmental impact. Choosing fingerjointed wood for Your projects supports eco-friendly construction and responsible forestry practices.

Common Applications and Use Cases

Fingerjointed wood is widely used in furniture manufacturing, interior trim, and moldings due to its stability and cost-efficiency, making it ideal for large-scale production and decorative purposes. Solid lumber remains the preferred choice for structural applications, high-end cabinetry, and flooring, where natural grain pattern and strength are essential. Your selection depends on whether you prioritize durability and aesthetic appeal or budget-friendly material with consistent performance.

Pros and Cons of Fingerjointed Wood

Fingerjointed wood offers enhanced stability and uniformity, reducing warping and defects compared to solid lumber, making it ideal for cost-effective construction and furniture projects. However, fingerjointed wood may have slightly lower strength and aesthetic appeal due to visible joints, which could impact the look and load-bearing capacity in certain applications. Your choice depends on balancing budget considerations with the desired durability and appearance for the project.

Pros and Cons of Solid Lumber

Solid lumber offers superior strength, natural beauty, and enhanced durability, making it ideal for furniture and structural applications requiring long-lasting performance. However, it is prone to warping, cracking, and shrinking due to moisture changes, and typically costs more than engineered alternatives like fingerjointed wood. Your choice should consider the balance between aesthetic quality and potential maintenance needs over time.

Fingerjointed wood vs solid lumber Infographic

libmatt.com

libmatt.com